Your Wire mesh for concrete pad images are ready. Wire mesh for concrete pad are a topic that is being searched for and liked by netizens today. You can Get the Wire mesh for concrete pad files here. Get all free vectors.

If you’re looking for wire mesh for concrete pad images information connected with to the wire mesh for concrete pad interest, you have visit the ideal blog. Our website frequently provides you with hints for refferencing the highest quality video and picture content, please kindly surf and locate more enlightening video articles and images that match your interests.

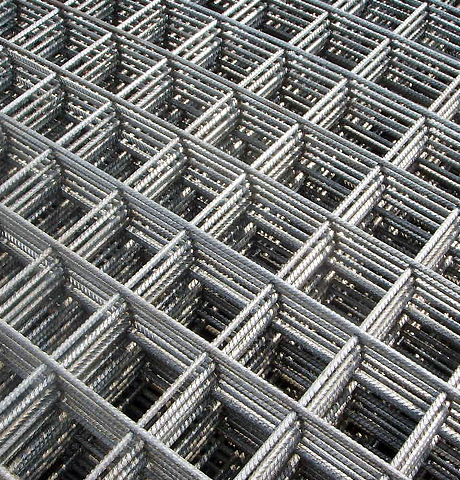

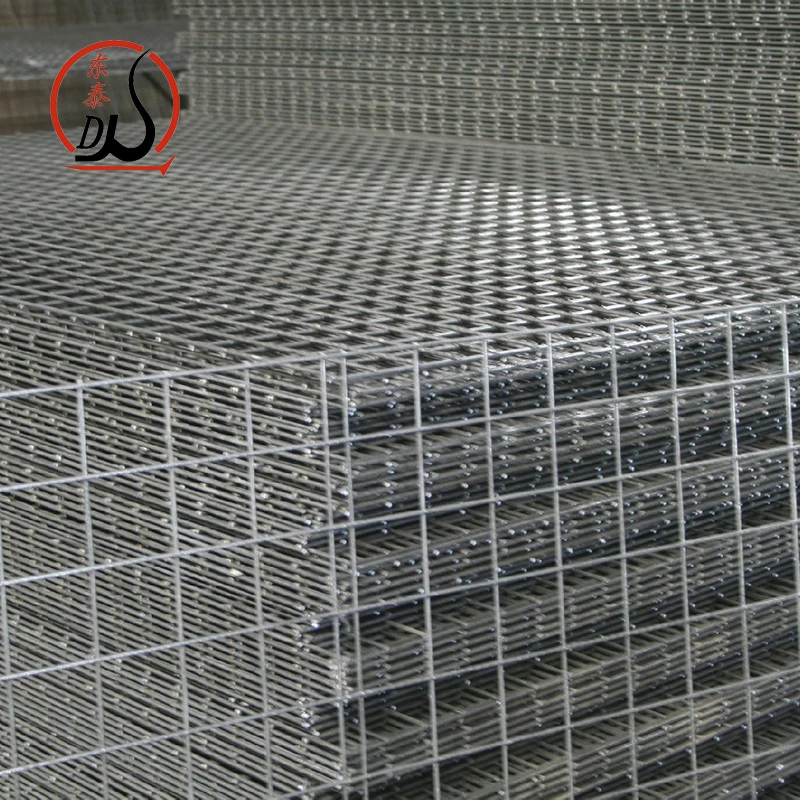

Wire Mesh For Concrete Pad. Welded wire mesh provides no increase in pavement structural capacity as some mistakenly believe. Lower labor and in-place costs and reduced liability. Steel mesh is a popular way to reinforce concrete. Galvanized tie wire or plastic clips should be used when assembling or installing galvanized bar and bar supports also should be galvanized steel.

232 Wire Mesh Concrete Slab Photos Free Royalty Free Stock Photos From Dreamstime From dreamstime.com

232 Wire Mesh Concrete Slab Photos Free Royalty Free Stock Photos From Dreamstime From dreamstime.com

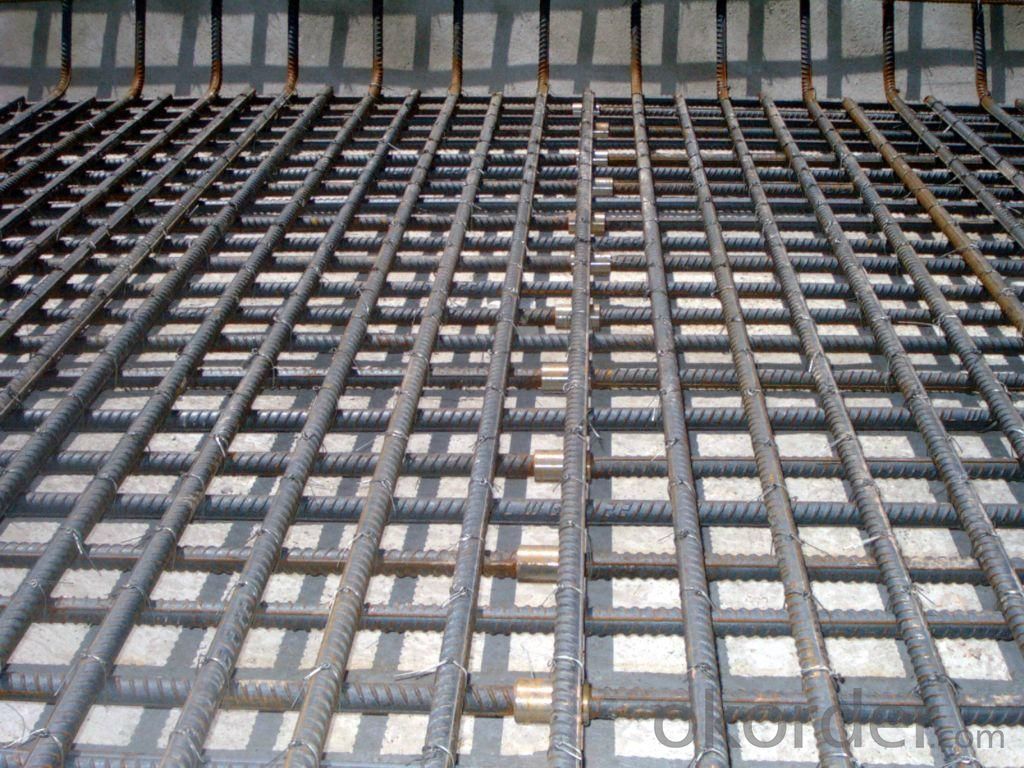

Tie into the existing slabs When youre joining two concrete slabs connect the two with rebar to keep them at the same height. If possible get wire mesh paneling pre-cut to size so you can lay it directly on top of the fill with minimal adjustments. This will give you the number of linear feet. -to resist breaking apart and deteriorating when the slab eventually does crack -to increase flexural strength of the slab. Also another situation where wire mesh can offer benefits is when a poor or weak subgrade exists and may be expected to move Skip to content HomeMenu. Concrete foundations should be a minimum of 4 1016cm thick and should be reinforced with either rebar or mesh.

The table provided in this slide lists common styles of welded wire fabric.

A L1L2 Divide the area number calculated in Step 3 by 5 as wire mesh in most commonly sold by the linear foot in 5-foot wide rolls. With the features of high strength high rigidity and corrosion rust resistant it is widely used for foundations reinforcing and roads reinforcing to improve concrete adhesion prevent the emergence of concrete cracks and increase the bearing weight and so on. When it comes to wire mesh you will typically see 6 gauge and 10 gauge. Wire mesh is available in stainless steel and polymer varieties too although these are often more expensive. To keep cracks tight the mesh has to be put in the correct place which is rarely done. Along with accurately estimating the quantities of concrete forms tools and labour for a project it is also important to be able to calculate the amount of wire mesh needed.

Source: marsarebar.com

Source: marsarebar.com

Now if the concrete pad has rebar and you can get to it for bonding use a approved clamp. If you include professional installation your overall cost of wire mesh will range between 094sf and 210sf. Wire mesh is commonly placed in concrete slabs for two primary reasons. It does not offer the strength that rebar does but it is very close. Once the wire mesh is in place you can pour the concrete flatten it level it and then cure it.

Source: 123rf.com

Source: 123rf.com

A L1L2 4 Divide the area number calculated in Step 3 by 5 as wire mesh in most commonly sold by the linear foot in 5-foot wide rolls. Concrete wire mesh prices range between 014sf and 060sf. If you include professional installation your overall cost of wire mesh will range between 094sf and 210sf. One may also ask how do you put rebar on a concrete pad. Finishes easily and smoothly with common.

Source: dreamstime.com

Source: dreamstime.com

Along with accurately estimating the quantities of concrete forms tools and labour for a project it is also important to be able to calculate the amount of wire mesh needed. A142 mesh is often used in 100mm thick light-use slabs such as paths driveways and garage bases while A252 is normally associated with heavier-duty 150-200mm thick slabs with A193 used in either. Many contractors use welded wire mesh to reinforce their concrete slabs. Multiply the measurements from Step 1 and Step 2 together. The past decade has seen many production builders switch to synthetic fiber mesh reinforcement for concrete slabs to help reduce surface cracking.

Source: alibaba.com

Source: alibaba.com

A L1L2 Divide the area number calculated in Step 3 by 5 as wire mesh in most commonly sold by the linear foot in 5-foot wide rolls. A L1L2 4 Divide the area number calculated in Step 3 by 5 as wire mesh in most commonly sold by the linear foot in 5-foot wide rolls. In either case a minimum of one chair per 25 square feet of mesh should be used to adequately support the reinforcement above the sub-grade. Tie into the existing slabs When youre joining two concrete slabs connect the two with rebar to keep them at the same height. -to resist breaking apart and deteriorating when the slab eventually does crack -to increase flexural strength of the slab.

Source: homedepot.com

Source: homedepot.com

This is generally manufactured from steel and sold in large sheets cut to size on the construction site. The most commonly specified steel fabrics for paving works are A142 6mm wires A193 7mm wires and A252 8mm wires. The past decade has seen many production builders switch to synthetic fiber mesh reinforcement for concrete slabs to help reduce surface cracking. Now if the concrete pad has rebar and you can get to it for bonding use a approved clamp. Concrete foundations should be a minimum of 4 1016cm thick and should be reinforced with either rebar or mesh.

Source: colourbox.com

Source: colourbox.com

Steel mesh unlike rebar is easily formed making it very popular. Ad Gratis Versand und eBay-Käuferschutz für Millionen von Artikeln. Galvanized tie wire or plastic clips should be used when assembling or installing galvanized bar and bar supports also should be galvanized steel. This reduction or elimination of plastic cracks enables the concrete to develop its optimum long-term integrity and increase robustness. One may also ask how do you put rebar on a concrete pad.

Source: dreamstime.com

Source: dreamstime.com

If possible get wire mesh paneling pre-cut to size so you can lay it directly on top of the fill with minimal adjustments. The table provided in this slide lists common styles of welded wire fabric. With the features of high strength high rigidity and corrosion rust resistant it is widely used for foundations reinforcing and roads reinforcing to improve concrete adhesion prevent the emergence of concrete cracks and increase the bearing weight and so on. Finishes easily and smoothly with common. Many contractors use welded wire mesh to reinforce their concrete slabs.

Source: reinforcingmesh.org

Source: reinforcingmesh.org

A L1L2 4 Divide the area number calculated in Step 3 by 5 as wire mesh in most commonly sold by the linear foot in 5-foot wide rolls. When using welded wire fabric prefabricated sheets should be used in lieu of rolled fabric in order to help assure proper location of the steel within the concrete. Concrete wire mesh prices range between 014sf and 060sf. The 10 gauge is a bit thinner and easier to work with and will serve the purpose of holding the top third together and help reduce the chances of cracking. To keep cracks tight the mesh has to be put in the correct place which is rarely done.

Source: reinforcingmesh.org

Source: reinforcingmesh.org

With the features of high strength high rigidity and corrosion rust resistant it is widely used for foundations reinforcing and roads reinforcing to improve concrete adhesion prevent the emergence of concrete cracks and increase the bearing weight and so on. Finishes easily and smoothly with common. Saves construction time-quicker pouring schedule. This will give you the number of linear feet of mesh needed. The steel mesh used to reinforce concrete looks just like any other type of fine woven material but made from metal.

Source: 123rf.com

Source: 123rf.com

If you include professional installation your overall cost of wire mesh will range between 094sf and 210sf. When using welded wire fabric prefabricated sheets should be used in lieu of rolled fabric in order to help assure proper location of the steel within the concrete. Compared to welded wire fabric or rebar there is no lifting cutting chairing tripping and scrapes. The job of WWM is to keep cracks tight that may form from environmental or traffic loading stresses. Unfortunately the mesh often ends up in the dirt at the bottom of the slab barely.

Source: ontariorebars.ca

Source: ontariorebars.ca

The past decade has seen many production builders switch to synthetic fiber mesh reinforcement for concrete slabs to help reduce surface cracking. But while fiber mesh has advantages it also comes with potentially costly drawbacks. Steel mesh unlike rebar is easily formed making it very popular. Lower labor and in-place costs and reduced liability. The past decade has seen many production builders switch to synthetic fiber mesh reinforcement for concrete slabs to help reduce surface cracking.

Source: dreamstime.com

Source: dreamstime.com

Concrete slab mesh is also called reinforced welded wire mesh which is made of galvanized stainless steel wires. Also another situation where wire mesh can offer benefits is when a poor or weak subgrade exists and may be expected to move Skip to content HomeMenu. It does not offer the strength that rebar does but it is very close. Rebar steel rods go around the footing and welded wire mesh goes into the main slab. Lower labor and in-place costs and reduced liability.

Source: okorder.com

Source: okorder.com

The job of WWM is to keep cracks tight that may form from environmental or traffic loading stresses. Also another situation where wire mesh can offer benefits is when a poor or weak subgrade exists and may be expected to move Skip to content HomeMenu. Multiply the measurements from Step 1 and Step 2 together. This reduction or elimination of plastic cracks enables the concrete to develop its optimum long-term integrity and increase robustness. One may also ask how do you put rebar on a concrete pad.

Source: shutterstock.com

Source: shutterstock.com

Welded wire mesh provides no increase in pavement structural capacity as some mistakenly believe. Many construction projects are now calling for welded wire mesh to be used in making concrete slabs instead of rebar. Can you use galvanized wire in concrete. This reduction or elimination of plastic cracks enables the concrete to develop its optimum long-term integrity and increase robustness. For me when using both rebar and mesh I feel the 6 gauge is overkill.

Source: indiamart.com

Source: indiamart.com

When placed within the framework of the concrete forms prior to pouring the pad wire mesh has proven to be an effective reinforcing material. For me when using both rebar and mesh I feel the 6 gauge is overkill. Welded wire mesh provides no increase in pavement structural capacity as some mistakenly believe. Compared to welded wire fabric or rebar there is no lifting cutting chairing tripping and scrapes. It does not offer the strength that rebar does but it is very close.

Source: homedepot.com

Source: homedepot.com

For me when using both rebar and mesh I feel the 6 gauge is overkill. Galvanized tie wire or plastic clips should be used when assembling or installing galvanized bar and bar supports also should be galvanized steel. Concrete slab mesh is also called reinforced welded wire mesh which is made of galvanized stainless steel wires. The most commonly specified steel fabrics for paving works are A142 6mm wires A193 7mm wires and A252 8mm wires. When it comes to wire mesh you will typically see 6 gauge and 10 gauge.

Source: 123rf.com

Source: 123rf.com

To keep cracks tight the mesh has to be put in the correct place which is rarely done. This resulting number is the area A in square feet of the concrete pad. A L1L2 4 Divide the area number calculated in Step 3 by 5 as wire mesh in most commonly sold by the linear foot in 5-foot wide rolls. One may also ask how do you put rebar on a concrete pad. Wire mesh allows for thinner slab pours and protects against future cracking by providing a framework for the concrete to hold to.

Source: knightscompanies.com

Source: knightscompanies.com

Compared to welded wire fabric or rebar there is no lifting cutting chairing tripping and scrapes. Lower labor and in-place costs and reduced liability. -to resist breaking apart and deteriorating when the slab eventually does crack -to increase flexural strength of the slab. Position the wire mesh about two inches from the forms using heavy-duty wire cutters to cut the edges as needed. Wire mesh allows for thinner slab pours and protects against future cracking by providing a framework for the concrete to hold to.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site adventageous, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title wire mesh for concrete pad by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.