Your What does cast in place concrete mean images are available. What does cast in place concrete mean are a topic that is being searched for and liked by netizens today. You can Get the What does cast in place concrete mean files here. Get all free photos.

If you’re looking for what does cast in place concrete mean pictures information linked to the what does cast in place concrete mean interest, you have pay a visit to the ideal blog. Our website always gives you hints for viewing the maximum quality video and image content, please kindly hunt and find more informative video content and graphics that fit your interests.

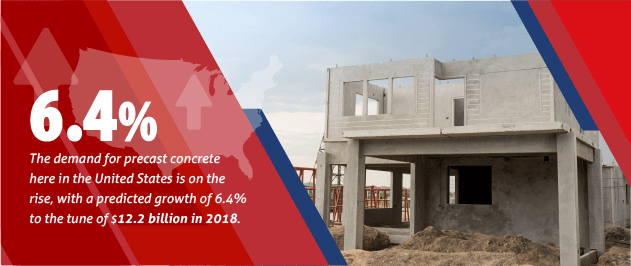

What Does Cast In Place Concrete Mean. Shells and folded plate members. 85 03 54 Cast Underlayment. What does CAST-IN-PLACE CONCRETE mean. Building better outcomes The Cellcast Floor System provides the first high-capacity low-cost wire and cable distribution system for cast-in-place concrete structures.

Simple Steel Beam Supported Cast In Place Concrete Floor On Corrugated Steel Decking Watch Out For The Wall Connection S Steel Beams Concrete Floors Concrete From pinterest.com

Simple Steel Beam Supported Cast In Place Concrete Floor On Corrugated Steel Decking Watch Out For The Wall Connection S Steel Beams Concrete Floors Concrete From pinterest.com

Building better outcomes The Cellcast Floor System provides the first high-capacity low-cost wire and cable distribution system for cast-in-place concrete structures. What does CIPC mean. If you are visiting our non-English version and want to see the English version of Cast-In-Place Concrete please scroll down to the bottom and you will see the meaning of Cast-In-Place Concrete in English language. 85 03 61 Cementitious Grouting. Cast-in-place Concrete often known as poured-in-place or cast in situ is a method of concreting that is carried out in situ or in the finished location of the concrete component. What is cast-in-situ concrete.

6 bar and large bars.

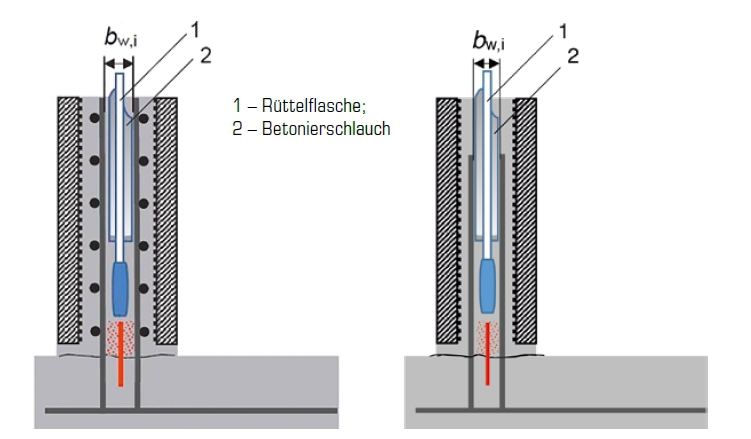

The clear cover for cast-in-place concrete is given in the below table. Concrete tilt-up panels cast against a rigid horizontal surface like concrete slab. The concrete is typically transported to site in an unhardened state. What is Cast In Place Concrete Cast in place concrete is the concrete uses that forms on site and is poured directly into those forms. High-slump concrete is then poured through a hopper placed on top of the casing to cast the pile shaft. What is cast-in-situ concrete.

Source: youtube.com

Source: youtube.com

03 48 Precast Concrete Specialties. The healthcare law looks promising but well have to wait until its cast in concrete before we know exactly what it will do. Sometimes it can be hard to control the mix when weather. 8 bar and smaller. 7Beams may or may not be present.

Source: in.pinterest.com

Source: in.pinterest.com

The shape and size looks good as it does not need to be shifted. For example some foundations and other very large concrete components would be difficult to transport between a concrete plant and job site making cast-in-place. Pouring concrete onsite is a common practice in trenchless construction. It involves pouring liquid concrete into removable forms and then dismantling the forms once the concrete has hardened to leave a solid wall behind. 84 03 53 Concrete Topping.

Source: sciencedirect.com

Source: sciencedirect.com

84 03 51 Cast Roof Decks. Cast-in-place concrete also known as site-cast or poured-in-place concrete is poured and cured onsite in the concretes finished position. Cast-in-place concrete is a common type of building material for commercial structures and residential homes alike. The healthcare law looks promising but well have to wait until its cast in concrete before we know exactly what it will do. Cast in situ concrete simply means the process of pouring liquid material which is concrete composed of mixture of cementsand and aggregate at the required ratio then poured into the mould or form work ieslab formwork or column formworkwhich is found at the building site.

Source: bft-international.com

Source: bft-international.com

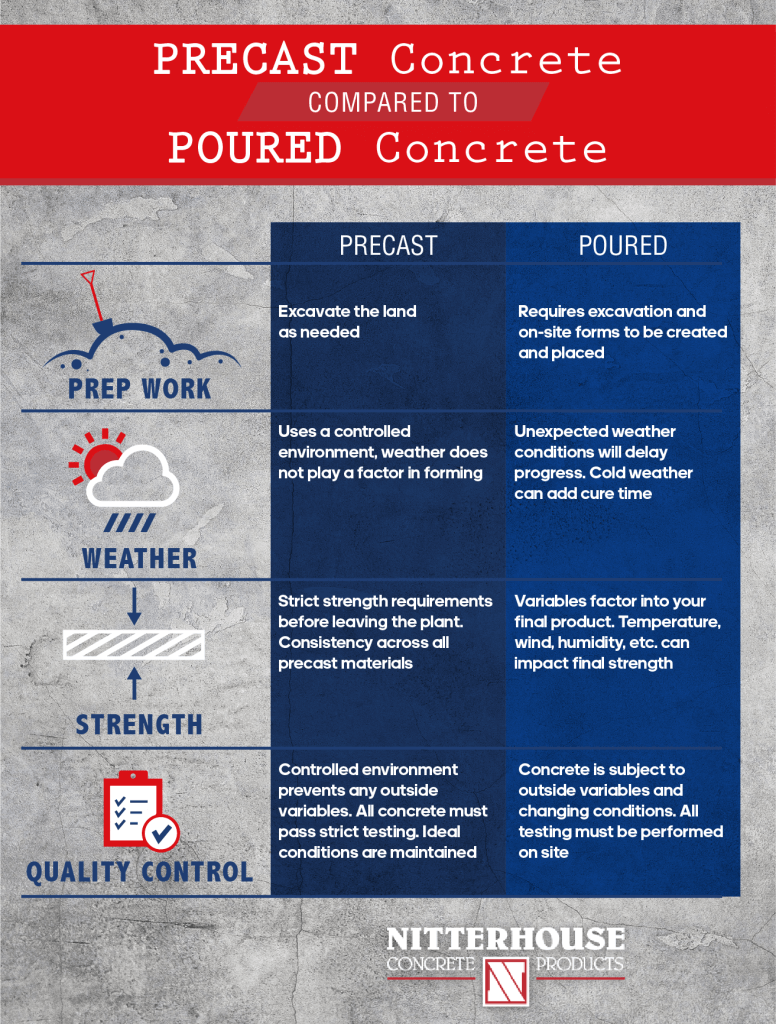

Maybe you were looking for one of these abbreviations. CIP or site cast concrete is prepared at local plants for construction site delivery via trucks with revolving drums. Cast-in-place concrete also known as poured-in-place is a concreting technique which is undertaken in situ or in the concrete components finished position. CIP concrete requires a strength test and additional time for curing on-site. 7a with uniform thickness is the simplest form of beamless slab constructionThe flat slab Fig.

Source: pinterest.com

Source: pinterest.com

Does this apply when placing concrete on c. 7a with uniform thickness is the simplest form of beamless slab constructionThe flat slab Fig. Cast-in-place concrete is a technology of construction of buildings where walls and slabs of the buildings are cast at the site in formwork. Show All 228Most Common 2Technology 55Government Military 68Science Medicine 32Business 53Organizations 53Slang Jargon 6 Acronym Definition CIP Capital Improvement Plan CIP Chartered Insurance Professional CIP Classification of Instructional Programs CIP Clean-In-Place CIP Capital Improvement Program CIP Critical. The concrete is typically transported to site in an unhardened state.

Source: pinterest.com

Source: pinterest.com

For specific applications this type of casting can be ideal. Cast in concrete Firmly or permanently established. 8 bar and smaller. This differs from precast concrete technology where slabs are cast elsewhere and then brought to the construction site and assembled. Cast-in-place concrete Cast-in- place concrete also known as poured-in- place is a concreting technique which is undertaken in situ or in the concrete components finished position.

Source: pinterest.com

Source: pinterest.com

Sometimes it can be hard to control the mix when weather. Does this apply when placing concrete on c. For example some foundations and other very large concrete components would be difficult to transport between a concrete plant and job site making cast-in-place. The shape and size looks good as it does not need to be shifted. Advertisement Trenchlesspedia Explains Site-Poured Concrete When it comes to pouring concrete construction operators often find that completing the process onsite makes sense.

Source: pinterest.com

Source: pinterest.com

We couldnt find any results for your search. It gains much strength to handle hazards and remains in solid state for long duration. The clear cover for cast-in-place concrete is given in the below table. Concrete tilt-up panels cast against a rigid horizontal surface like concrete slab. Cast-in-place concrete is a technology of construction of buildings where walls and slabs of the buildings are cast at the site in formwork.

Source: nitterhousemasonry.com

Source: nitterhousemasonry.com

84 03 53 Concrete Topping. 7a with uniform thickness is the simplest form of beamless slab constructionThe flat slab Fig. The flat plate Fig. In-situ is manual concrete poured in a form of liquid and become rigid. 84 03 52 Lightweight Concrete Roof Insulation.

Source: pinterest.com

Source: pinterest.com

We couldnt find any results for your search. 7Beams may or may not be present. It is also easy to repair in future if gets cracked. Advertisement Trenchlesspedia Explains Site-Poured Concrete When it comes to pouring concrete construction operators often find that completing the process onsite makes sense. The shape and size looks good as it does not need to be shifted.

Source: sciencedirect.com

Source: sciencedirect.com

Cast-in- place concrete is the preferred choice for concrete slabs and foundations as well as components such as beams columns walls roofs and so on. Cast-in-place concrete is a common type of building material for commercial structures and residential homes alike. Site-poured concrete is also known as in-situ concrete or cast-in-place concrete. Cast-in-place Concrete often known as poured-in-place or cast in situ is a method of concreting that is carried out in situ or in the finished location of the concrete component. Cast-in-place concrete also known as site-cast or poured-in-place concrete is poured and cured onsite in the concretes finished position.

Source: nitterhouseconcrete.com

Source: nitterhouseconcrete.com

CIPC stands for Cast-In-Place Concrete. According to ACI concrete cast against and permanently exposed to earth is to have a minimum cover of 3 ACI 771. Maybe you were looking for one of these abbreviations. Cast-in-place concrete is a common type of building material for commercial structures and residential homes alike. Building better outcomes The Cellcast Floor System provides the first high-capacity low-cost wire and cable distribution system for cast-in-place concrete structures.

Source: gharpedia.com

Source: gharpedia.com

03 48 Precast Concrete Specialties. Cast-in-place concrete also known as poured-in-place is a concreting technique which is undertaken in situ or in the concrete components finished position. What is Cast-in-Place CIP Concrete. It is also easy to repair in future if gets cracked. For specific applications this type of casting can be ideal.

Source: trenchlesspedia.com

Source: trenchlesspedia.com

Cast-in-place concrete also known as poured-in-place is a concreting technique which is undertaken in situ or in the concrete components finished position. Advertisement Trenchlesspedia Explains Site-Poured Concrete When it comes to pouring concrete construction operators often find that completing the process onsite makes sense. Cast-in-place Concrete often known as poured-in-place or cast in situ is a method of concreting that is carried out in situ or in the finished location of the concrete component. 03 48 Precast Concrete Specialties. Sometimes it can be hard to control the mix when weather.

Source: nitterhouseconcrete.com

Source: nitterhouseconcrete.com

What is cast-in-situ concrete. Cast-in-place concrete Cast-in- place concrete also known as poured-in- place is a concreting technique which is undertaken in situ or in the concrete components finished position. There are two ways to cast a concrete for building in-situ as per your question and pre-cast the category is based on where the concrete will be casted. This page is about the various possible meanings of the acronym abbreviation shorthand or slang term. CIP concrete requires a strength test and additional time for curing on-site.

Source: nitterhouseconcrete.com

Source: nitterhouseconcrete.com

Pouring concrete onsite is a common practice in trenchless construction. Cast-in-place concrete buildings have lower floor-to-floor heights than other materials. CIPC stands for Cast-In-Place Concrete. 84 03 51 Cast Roof Decks. 6 bar and large bars.

Source: id.pinterest.com

Source: id.pinterest.com

It involves pouring liquid concrete into removable forms and then dismantling the forms once the concrete has hardened to leave a solid wall behind. It gains much strength to handle hazards and remains in solid state for long duration. There are two ways to cast a concrete for building in-situ as per your question and pre-cast the category is based on where the concrete will be casted. According to ACI concrete cast against and permanently exposed to earth is to have a minimum cover of 3 ACI 771. What is Cast-in-Place CIP Concrete.

Source: nitterhouseconcrete.com

Source: nitterhouseconcrete.com

What is Cast-in-Place CIP Concrete. Cast-in-place concrete buildings have lower floor-to-floor heights than other materials. What does CIPC mean. Site-poured concrete is also known as in-situ concrete or cast-in-place concrete. Building better outcomes The Cellcast Floor System provides the first high-capacity low-cost wire and cable distribution system for cast-in-place concrete structures.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site value, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title what does cast in place concrete mean by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.