Your Sub base material for concrete slab images are ready. Sub base material for concrete slab are a topic that is being searched for and liked by netizens now. You can Download the Sub base material for concrete slab files here. Download all free photos and vectors.

If you’re searching for sub base material for concrete slab images information related to the sub base material for concrete slab keyword, you have visit the right site. Our website always provides you with suggestions for seeing the highest quality video and image content, please kindly hunt and locate more enlightening video content and images that match your interests.

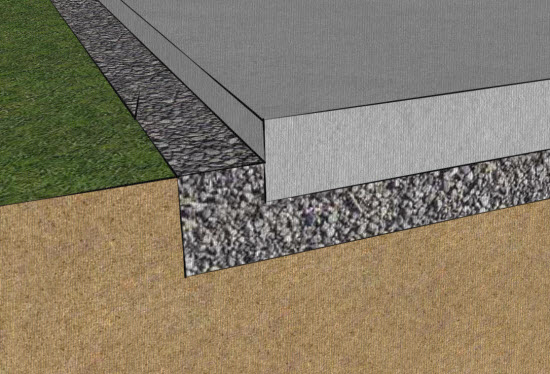

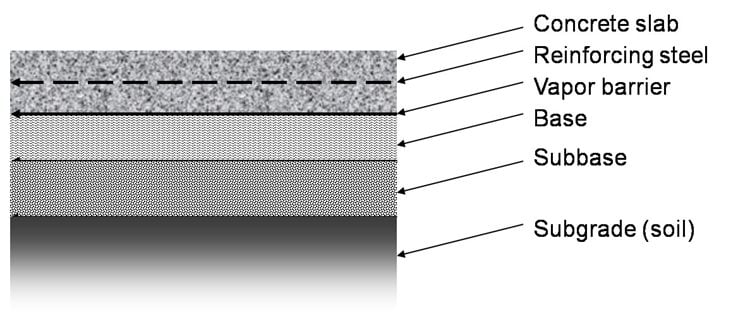

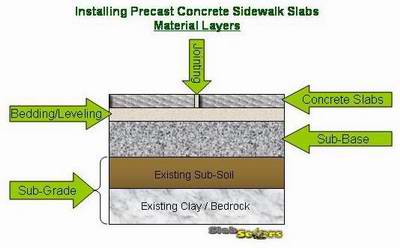

Sub Base Material For Concrete Slab. A subbase will go on top of the subgrade which typically is native soil or improved soil that has been compacted. Subgrades Subbases For Concrete Slabs The Network. Either way the subgrade soil needs to be flat and compacted. The plan is 3 12 of concrete over a base material.

Plain Concrete Hardstandings Pavingexpert From pavingexpert.com

Plain Concrete Hardstandings Pavingexpert From pavingexpert.com

We do not take any responsibility for. Either way the subgrade soil needs to be flat and compacted. Theres a rule of thumb that we use with fill layers - they should always be at least twice the thickness of the largest particle size. This pivotal work on rigid pavement design by the US. The base course material according to ACI 302 Concrete Floor and Slab Construction should be compactible easy to trim granular fill that will remain stable and support construction traffic ACI 302 recommends material with 10 to 30 fines passing the No. Proper Subgrade Prep Concrete Construction Magazine.

The Utilization of Slag in Civil Infrastructure Construction 2016 Download as PDF About this page.

- Hi All Hoping for a bit of advice. Army Corps of Engineers led to a much better understanding of the importance of the use of bases and subbases their uniformity and degree of compaction. Subbase for Concrete Slab Subbase is a layer of gravel which is fairly cheap material placed on top of subgrade. Subbase Material Subbase material has specific size requirements. But typically the tamped base should be equal to your concretes thickness ie. Subbase is often the main load-bearing layer of the pavementIts role is to spread the load evenly over the subgrade.

Source: thespruce.com

Source: thespruce.com

They may be placed to improve sub-grade support values to expedite construction or to avert sub-grade frost heave in a freezer warehouse or ice rink. Check with your municipality. Proper Subgrade Prep Concrete Construction Magazine. In concrete pavement terminology the subgrade the native soil on which the pavement is built must be protected and compacted to ensure it stays in its place and isnt damaged. It is important for a subbase to have solid edges and joints to prevent cracking and concrete spalling.

Source: researchgate.net

Source: researchgate.net

They may be placed to improve sub-grade support values to expedite construction or to avert sub-grade frost heave in a freezer warehouse or ice rink. As this is purely an estimate for perfectly level ground we highly recommend seeking advice from a professional landscaper before buying any concrete sand or sub-base. Bricks Masonry Cinder Block Paving Walking Stones Asphalt and Concrete - What base material under concrete slab. A subbase also will make the concrete work easier because a soil subgrade can get muddy and make a mess during the concrete pour. Why is a Concrete Slab Base Necessary.

Source: slabsetters.com

Source: slabsetters.com

Aggregates The Difference Between Crushed Stone And Gravel. 4-inch base for 4-inch slab. Theres a rule of thumb that we use with fill layers - they should always be at least twice the thickness of the largest particle size. Check with your municipality. They may be placed to improve sub-grade support values to expedite construction or to avert sub-grade frost heave in a freezer warehouse or ice rink.

Source: globalrailwayreview.com

Source: globalrailwayreview.com

3 Reasons To Use Crushed Stone Under Concrete Slabs B R Sand. 4-inch base for 4-inch slab. Concrete slabs were placed directly on top of the subgrade without any basesubbase layers. If your building code permits it be sure to include floor drains. This pivotal work on rigid pavement design by the US.

Subbase for Concrete Slab Subbase is a layer of gravel which is fairly cheap material placed on top of subgrade. Proper Subgrade Prep Concrete Construction Magazine. In highway engineering subbase is the layer of aggregate material laid on the subgrade on which the base course layer is located. Geotechnical engineers typically are contracted by owners to evaluate soil conditions on a construction site and sometimes they specify the subbase fill materials to be used and how they should be placed. The plan is 3 12 of concrete over a base material.

Source: specifyconcrete.org

Source: specifyconcrete.org

The base in concrete construction is the layer between the sub-grade existing soil and the concrete slab. The base in concrete construction is the layer between the sub-grade existing soil and the concrete slab. Special sub-bases are used for a variety of reasons. It is important for a subbase to have solid edges and joints to prevent cracking and concrete spalling. This is done by laying down a sub-base a layer of aggregate material that is placed above the subgrade to prevent soil displacement.

Source: pinterest.com

Source: pinterest.com

This is done by laying down a sub-base a layer of aggregate material that is placed above the subgrade to prevent soil displacement. As this is purely an estimate for perfectly level ground we highly recommend seeking advice from a professional landscaper before buying any concrete sand or sub-base. One of the key findings during the implementation of the new design procedure. Either way the subgrade soil needs to be flat and compacted. Theres a rule of thumb that we use with fill layers - they should always be at least twice the thickness of the largest particle size.

Source: concretenetwork.com

Source: concretenetwork.com

It can be clay soil dirt none of it will matter when you have a proper layer under the concrete. Subbase is often the main load-bearing layer of the pavementIts role is to spread the load evenly over the subgrade. A subgrade is made up of native soil that has been compacted to withstand the loads above it. In highway engineering subbase is the layer of aggregate material laid on the subgrade on which the base course layer is located. Geotechnical engineers typically are contracted by owners to evaluate soil conditions on a construction site and sometimes they specify the subbase fill materials to be used and how they should be placed.

Source: concretenetwork.com

Source: concretenetwork.com

Though 6-inches of each is largely the. Army Corps of Engineers led to a much better understanding of the importance of the use of bases and subbases their uniformity and degree of compaction. Aggregates The Difference Between Crushed Stone And Gravel. One of the key findings during the implementation of the new design procedure. 3 Reasons To Use Crushed Stone Under Concrete Slabs B R Sand.

Source: pavingexpert.com

Source: pavingexpert.com

The Utilization of Slag in Civil Infrastructure Construction 2016 Download as PDF About this page. The subbase placement is optional and it serves as a work platform for construction of the slab and provide more uniform support for the slab. It is important for a subbase to have solid edges and joints to prevent cracking and concrete spalling. The subbase is the finely graded compactable material between the subgrade and the concrete. A subbase also will make the concrete work easier because a soil subgrade can get muddy and make a mess during the concrete pour.

Source: secrets-of-shed-building.com

Source: secrets-of-shed-building.com

Geotechnical engineers typically are contracted by owners to evaluate soil conditions on a construction site and sometimes they specify the subbase fill materials to be used and how they should be placed. This calculator will provide you with an estimate of how much concrete sand weed membrane and sub-base you will need for your paving project. A subbase will go on top of the subgrade which typically is native soil or improved soil that has been compacted. Army Corps of Engineers led to a much better understanding of the importance of the use of bases and subbases their uniformity and degree of compaction. This pivotal work on rigid pavement design by the US.

Source: pavingexpert.com

Source: pavingexpert.com

In highway engineering subbase is the layer of aggregate material laid on the subgrade on which the base course layer is located. Geotechnical engineers typically are contracted by owners to evaluate soil conditions on a construction site and sometimes they specify the subbase fill materials to be used and how they should be placed. This pivotal work on rigid pavement design by the US. Gravel Vs Concrete Shed Base Which Is A Better Choice. Aggregates The Difference Between Crushed Stone And Gravel.

Source: constrofacilitator.com

Source: constrofacilitator.com

The subbase is literally the foundation and with it you dont have to worry about the subgrade material. Old homes had these and the slab sloped. This is done by laying down a sub-base a layer of aggregate material that is placed above the subgrade to prevent soil displacement. This pivotal work on rigid pavement design by the US. If you are adding a subbase dig down least four inches deeper than the thickness of your concrete and compact the soil.

Source: concretenetwork.com

Source: concretenetwork.com

Generally a flexible sub-base of unbound material needs to be at least 100mm deep as does a bound sub-base of CBMHBM. Gravel Vs Concrete Shed Base Which Is A Better Choice. One of the key findings during the implementation of the new design procedure. We do not take any responsibility for. If you are adding a subbase dig down least four inches deeper than the thickness of your concrete and compact the soil.

Source: concretenetwork.com

Source: concretenetwork.com

It is important for a subbase to have solid edges and joints to prevent cracking and concrete spalling. Special sub-bases are used for a variety of reasons. They can consist of materials such as crushed stone recycled concrete asphalt lean concrete and rigid insulation. Bricks Masonry Cinder Block Paving Walking Stones Asphalt and Concrete - What base material under concrete slab. Although it is recommended to have a good subgrade preparation in place before putting in the gravel.

Source: concretenetwork.com

Source: concretenetwork.com

Although it is recommended to have a good subgrade preparation in place before putting in the gravel. The sub-base material should be spread out in layers no thicker than 150mm and roughly levelled with spades rakes or similar. The subbase placement is optional and it serves as a work platform for construction of the slab and provide more uniform support for the slab. In concrete pavement terminology the subgrade the native soil on which the pavement is built must be protected and compacted to ensure it stays in its place and isnt damaged. Generally a flexible sub-base of unbound material needs to be at least 100mm deep as does a bound sub-base of CBMHBM.

Source: tristar-concrete.com

Source: tristar-concrete.com

One of the key findings during the implementation of the new design procedure. Old homes had these and the slab sloped. They may be placed to improve sub-grade support values to expedite construction or to avert sub-grade frost heave in a freezer warehouse or ice rink. Army Corps of Engineers led to a much better understanding of the importance of the use of bases and subbases their uniformity and degree of compaction. One of the key findings during the implementation of the new design procedure.

Source: slabsetters.com

Source: slabsetters.com

Special sub-bases are used for a variety of reasons. As this is purely an estimate for perfectly level ground we highly recommend seeking advice from a professional landscaper before buying any concrete sand or sub-base. In concrete pavement terminology the subgrade the native soil on which the pavement is built must be protected and compacted to ensure it stays in its place and isnt damaged. Theres a rule of thumb that we use with fill layers - they should always be at least twice the thickness of the largest particle size. 100 sieve with no clay silt or organic materials.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site good, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title sub base material for concrete slab by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.