Your Standard concrete wall form sizes images are available. Standard concrete wall form sizes are a topic that is being searched for and liked by netizens today. You can Find and Download the Standard concrete wall form sizes files here. Find and Download all royalty-free photos.

If you’re searching for standard concrete wall form sizes pictures information linked to the standard concrete wall form sizes keyword, you have visit the right site. Our site always provides you with hints for seeking the highest quality video and image content, please kindly search and locate more enlightening video content and images that fit your interests.

Standard Concrete Wall Form Sizes. It is made in thicknesses. As to width a residential basement is usually 8 but you can make them any size you want. Specifications subject to change without notice Concrete Form Panels and Fillers Quality Features Outside and Inside Corners Form Braces - Steel Pipe Turnbuckle Braces Using Modular Wall Forms Typical Applications. 5272016 8 Ability to be shaped Bent ply Steel sheets 2D curved shapes by casting.

Insulated Concrete Forms For Walls Insulated Concrete Forms Concrete Forms Concrete House Plans From pinterest.com

Insulated Concrete Forms For Walls Insulated Concrete Forms Concrete Forms Concrete House Plans From pinterest.com

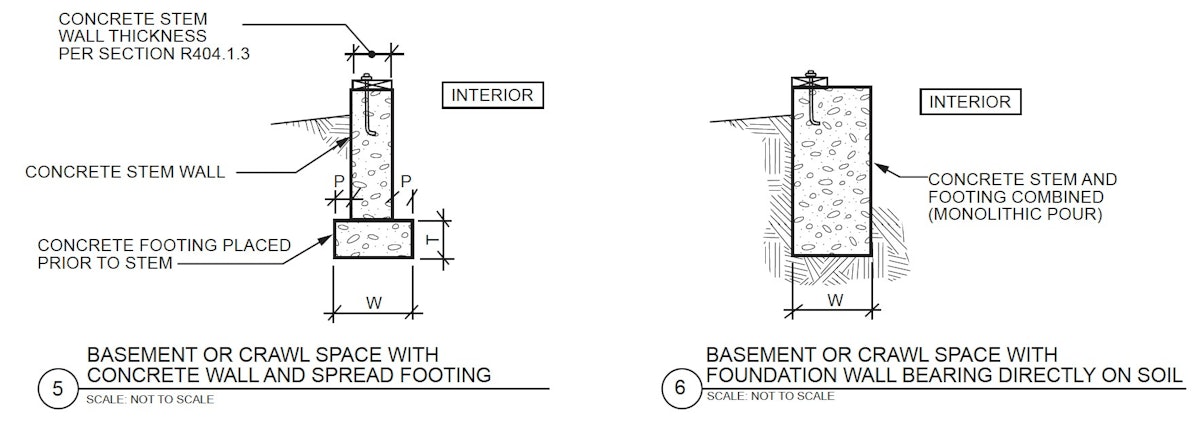

A3B1 Combination Ties are manufactured with a standard forged head on one end and 12 coil tie on another. Equipment weighing 3500-12000 lbs. And shipped as a kit to your jobsite. Below grade walls must have a minimum 6 150 mm concrete core. Formed concrete walls are built as foundation or retaining members in construction. It is made in thicknesses.

406 mm available in nominal thicknesses of 4 6 8 10 12 14 and 16 in.

The in-sert is available for use with standard wood or plastic chamfer strips and the manufacturer says its impossible to install incorrectly. A3B1 Combination Ties are manufactured with a standard forged head on one end and 12 coil tie on another. Will require a form made of 18 10gauge steel. An advantage of using plywood for forms is the great number of sizes available. However plywood used for this purpose should be made with waterproof glue and marked for use in concrete forms. Below grade walls must have a minimum 6 150 mm concrete core.

Below grade walls must have a minimum 6 150 mm concrete core. The 4 100 mm form may be used for above grade walls up to a maximum of 10 30 m. HDO CONCRETE FORM B-B CLASS I EXT 0703 IN. C Cinci-Hal Registered Joined Jan 2 2012 5 Posts Discussion Starter 3 Oct 16 2015 Thanks for your response. Specifications subject to change without notice Concrete Form Panels and Fillers Quality Features Outside and Inside Corners Form Braces - Steel Pipe Turnbuckle Braces Using Modular Wall Forms Typical Applications.

Source: pinterest.com

Source: pinterest.com

But you dont have to be an engineer to size the forms for straightforward pourseven the 8 ft. Poured concrete foundation walls that are less than 8 feet tall and have soil outside that is 6 or 7 feet deep against the wall can often be 8 inches thick and function quite well. But you dont have to be an engineer to size the forms for straightforward pourseven the 8 ft. Commonly available in 1932 58 1116 2332 and 34 Performance Categories 4 x 8 size. Understand form face qualities Range of repeated use Cost Quality Potential shapesforms Finish of concrete produced Size Fixing method Edge conditions Relationship with release agent Image courtesy of Peri Galileo Satellite Control Centre Oberpfaffenhofen Germany.

Source: oas.org

Source: oas.org

APA 000 PS 1-09 2332 CAT MDO CONCRETE FORM B-B CLASS I EXT 0578 IN. Wooden Forms Wooden form is the basic and the most conventional type of concrete form. Plywood is warp-resistant and can be used more often than other lumber. These are either nailed or screwed together to the desired mold or formwork shape. DURAFORM was the first to offer chamfered edges and an improved edge seal.

Will require a form made of 18 10gauge steel. As soon as you go higher or have greater depths of soil pushing against the wall you need to increase the thickness to 10 inches. 5272016 8 Ability to be shaped Bent ply Steel sheets 2D curved shapes by casting. This together with pre-formed right and left-handed corners makes for a very fast building method. Plywood is warp-resistant and can be used more often than other lumber.

Source: jlconline.com

Source: jlconline.com

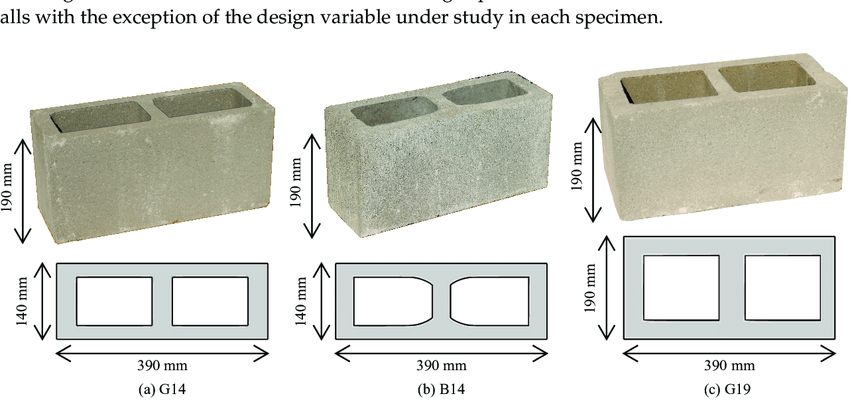

1 18 structural 1 grade forming plywood made of 100 Douglas Fir with 11 plys for added strength and durability. Actual Size 3 58 x 7 58 x 7 58 Nominal Size 4 x 8 x 8. A list of the standard size of CMUs can be helpful if you have any questions about the project or the mortar joint. The 4 100 mm form may be used for above grade walls up to a maximum of 10 30 m. Plywood is economical to use for wall and floor forms.

5272016 8 Ability to be shaped Bent ply Steel sheets 2D curved shapes by casting. HDO CONCRETE FORM B-B CLASS I EXT 0703 IN. 4 to 15 ft. Concrete Wall forms Steel Forms 1. Understand form face qualities Range of repeated use Cost Quality Potential shapesforms Finish of concrete produced Size Fixing method Edge conditions Relationship with release agent Image courtesy of Peri Galileo Satellite Control Centre Oberpfaffenhofen Germany.

Source: researchgate.net

Source: researchgate.net

APA 000 PS 1-09 1932 CAT 6FORM NO. Poured concrete foundation walls that are less than 8 feet tall and have soil outside that is 6 or 7 feet deep against the wall can often be 8 inches thick and function quite well. All opening sizes provided by the builder will be considered as concrete to concrete dimensions unless otherwise noted on the plan. A3B1 Combination Ties are used for connecting site-built wood forms to coil rod for blind-side wall application. Of 4 rebar in the header.

Source: researchgate.net

Source: researchgate.net

Each 8 thick by 24 inches wide panel can be cut to the inch to lengths up to 20 long or pre-cut to project specifications for windows and doors. Many consider aluminum and steel wall forming systems to be more productive efficient and even economical than wood forming. As to width a residential basement is usually 8 but you can make them any size you want. These wall systems require some form of insulation and an interior wallfinishing system to complete the building enclosures. These are either nailed or screwed together to the desired mold or formwork shape.

Source: pinterest.com

Source: pinterest.com

Concrete wall forms are typically made of plywood aluminum or steel. The 4 100 mm form cannot be used below grade as a foundation wall. 406 mm available in nominal thicknesses of 4 6 8 10 12 14 and 16 in. Specifications subject to change without notice Concrete Form Panels and Fillers Quality Features Outside and Inside Corners Form Braces - Steel Pipe Turnbuckle Braces Using Modular Wall Forms Typical Applications. Plywood is economical to use for wall and floor forms.

Of 4 rebar in the header. The in-sert is available for use with standard wood or plastic chamfer strips and the manufacturer says its impossible to install incorrectly. This concrete FORM panel is a large tough quick setup panel with snap together edges that form a strong straight flat pre-finished wall greatly reducing your setup and finishing time. Nominal size 34 inch 1 inch Connects to standard chamfer strip 6 in. Concrete Block Sizes.

Source: oas.org

Source: oas.org

Concrete wall forms are typically made of plywood aluminum or steel. Openings up to 4 wide have 2 pcs. But you dont have to be an engineer to size the forms for straightforward pourseven the 8 ft. Openings 4 to 8 wide have 3 pcs. Actual Size 3 58 x 7 58 x 7 58 Nominal Size 4 x 8 x 8.

Source: forconstructionpros.com

Source: forconstructionpros.com

This concrete FORM panel is a large tough quick setup panel with snap together edges that form a strong straight flat pre-finished wall greatly reducing your setup and finishing time. 1 18 structural 1 grade forming plywood made of 100 Douglas Fir with 11 plys for added strength and durability. The 4 100 mm form may be used for above grade walls up to a maximum of 10 30 m. The in-sert is available for use with standard wood or plastic chamfer strips and the manufacturer says its impossible to install incorrectly. 10 to 50 ft.

10 to 50 ft. In some regions an 8 200 mm concrete core is the minimum allowed thickness for below grade walls. Formed concrete walls are built as foundation or retaining members in construction. Walls that are typically cast for basements or retaining walls. Plywood is warp-resistant and can be used more often than other lumber.

The 4 100 mm form cannot be used below grade as a foundation wall. As soon as you go higher or have greater depths of soil pushing against the wall you need to increase the thickness to 10 inches. 4 to 15 ft. Plywood is economical to use for wall and floor forms. Of 4 rebar in the header.

Source: engineer-educators.com

Source: engineer-educators.com

Plywood is warp-resistant and can be used more often than other lumber. This concrete FORM panel is a large tough quick setup panel with snap together edges that form a strong straight flat pre-finished wall greatly reducing your setup and finishing time. Actual Size 3 58 x 7. A3B1 Combination Ties are used for connecting site-built wood forms to coil rod for blind-side wall application. Openings 4 to 8 wide have 3 pcs.

Source: surebuilt-usa.com

Source: surebuilt-usa.com

Check dealer for availability in your area. 10 to 50 ft. This concrete FORM panel is a large tough quick setup panel with snap together edges that form a strong straight flat pre-finished wall greatly reducing your setup and finishing time. Plywood is warp-resistant and can be used more often than other lumber. Will require a form made of 18 10gauge steel.

Source: researchgate.net

Source: researchgate.net

It is employed mainly for concrete casting that does not exceed 6 inches of height. A list of the standard size of CMUs can be helpful if you have any questions about the project or the mortar joint. Walls that are typically cast for basements or retaining walls. Of 4 rebar in the header. Will require a form made of 18 10gauge steel.

Source: oas.org

Source: oas.org

Concrete Block Sizes. Plywood is warp-resistant and can be used more often than other lumber. As soon as you go higher or have greater depths of soil pushing against the wall you need to increase the thickness to 10 inches. This together with pre-formed right and left-handed corners makes for a very fast building method. Giving Form to Concrete Ideas.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site adventageous, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title standard concrete wall form sizes by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.