Your Shrinkage cracking in concrete slab images are ready. Shrinkage cracking in concrete slab are a topic that is being searched for and liked by netizens now. You can Find and Download the Shrinkage cracking in concrete slab files here. Find and Download all free images.

If you’re searching for shrinkage cracking in concrete slab images information connected with to the shrinkage cracking in concrete slab interest, you have pay a visit to the right site. Our site always gives you suggestions for viewing the highest quality video and picture content, please kindly hunt and find more enlightening video articles and graphics that fit your interests.

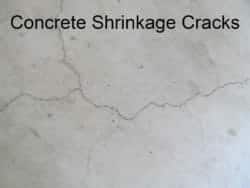

Shrinkage Cracking In Concrete Slab. Drying shrinkage is the contraction in the concrete caused by moisture loss from drying concrete. Shrinkage cracks in concrete occur due to change in moisture of concrete. This amount of steel controls cracking if its placed near the top of the slab with 3 4 to 1 inch of cover. These cracks are deeper and farther apart and also are caused by drying as surface moisture evaporates.

Applied Sciences Free Full Text Early Age Cracking In Concrete Causes Consequences Remedial Measures And Recommendations Html From mdpi.com

Applied Sciences Free Full Text Early Age Cracking In Concrete Causes Consequences Remedial Measures And Recommendations Html From mdpi.com

Shrinkage reinforcement to produce a cross-sectional area of steel at least 000075 times the area of concrete. This expansion can crack the concrete surface. This is the main cause of concrete shrinkage cracks on drying. Shrinkage cracks are not continuous through the slab but are actually cracks in the concrete surface. However there is sometimes too much emphasis on the drying shrinkage of hardened concrete as the criterion of susceptibility to cracking. These factors can cause high rates of evaporation in either hot or cold weathers.

Too much water results in shrinkage cracks as the concrete cures.

Thin members with a large surface area such as slabs are particularly vulnerable. Plastic shrinkage cracks can appear on the slab. Crack in concrete slab Sometimes depending on the necessity the aggregates added in the concrete have low shrinkage. Is for workability and placement purposes. Expansion results as steel is converted to iron oxide through corrosion. As an example where concrete pumps are involved and the operators are inexperienced they may add extra water through the line especially if its been held up for long.

Source: prugarinc.com

Source: prugarinc.com

As the path of cracking caused by concrete shrinkage wanders and stops and starts across an area of wall or floor you will often see overlapping or roughly parallel nearby cracks that represent the end of one crack line and the beginning of another. Commentary Provision R2431 of ACI 318-19 discusses flexural reinforcement for one-way slabs and beams. Is for workability and placement purposes. What is concrete slab drying shrinkage cracking. These cracks are deeper and farther apart and also are caused by drying as surface moisture evaporates.

Source: giatecscientific.com

Source: giatecscientific.com

They can be up to 3 mm wide at the surface but usually taper quickly over their depth but may penetrate right through a concrete element. What is concrete slab drying shrinkage cracking. The loss of moisture from fresh concrete results in a reduction in volume. Discussed below are different types of cracks that may occur in concrete slab pavement. Typically that concrete contains more water than is required to hydrate the cementitious materials the mixture contains.

Source: constrofacilitator.com

Source: constrofacilitator.com

Plastic shrinkage cracking occurs when fresh concrete is subjected to a very rapid loss of moisture. When the evaporation rate is higher than the bleeding rate the top of the slab surface shrinks due to drying and cracks at the end. In the photograph shown here the floor was badly cracked from a combination of concrete shrinkage settlement and frost heaves the building had been left un-heated in a freezing climate. Plastic shrinkage cracks in concrete slabs. Shrinkage-compensating concrete is used to minimize cracking and structural movement caused by drying shrinkage in concrete.

Source: researchgate.net

Source: researchgate.net

These factors can cause high rates of evaporation in either hot or cold weathers. June 2005 D ata sheet. In the photograph shown here the floor was badly cracked from a combination of concrete shrinkage settlement and frost heaves the building had been left un-heated in a freezing climate. Giuseppe Tiberti 1 ID Antonio Mudadu 1 Bryan Barragan 2 and Giovanni Plizzari 1. These cracks occur due to the water loss from the concrete.

Source: civilmedium.com

Source: civilmedium.com

Usually concrete slabs undergo high evaporation due to their large surface area. 1 Department of Civil. However there is sometimes too much emphasis on the drying shrinkage of hardened concrete as the criterion of susceptibility to cracking. 1nonlinear structural analysis with time steps shrinkage development with time and mechanical properties considered through the equations of EC2 available in Diana. Synthetic fibers can help prevent plastic shrinkage cracking as can fogging to reduce evaporation.

Source: theconstructor.org

Source: theconstructor.org

Crack in concrete slab Sometimes depending on the necessity the aggregates added in the concrete have low shrinkage. Shrinkage of concrete is an irreversible process. In this tutorial we study the shrinkage effects on a RC slab and the risk of cracking by considering three different approaches. As the path of cracking caused by concrete shrinkage wanders and stops and starts across an area of wall or floor you will often see overlapping or roughly parallel nearby cracks that represent the end of one crack line and the beginning of another. Discussed below are different types of cracks that may occur in concrete slab pavement.

Source: inspectapedia.com

Source: inspectapedia.com

Is for workability and placement purposes. Drying shrinkage alone is influenced by many factors - watercement ratio. Cracking typically starts within 12 hours of this finishing process but it may be slowed or accelerated by weather conditions. As the path of cracking caused by concrete shrinkage wanders and stops and starts across an area of wall or floor you will often see overlapping or roughly parallel nearby cracks that represent the end of one crack line and the beginning of another. That provision indicates that visible cracks will develop under service loads and crack widths are usually widely scattered and influenced by.

Source: cti-ia.net

Source: cti-ia.net

It is caused by a combination of factors such as. Cracking typically starts within 12 hours of this finishing process but it may be slowed or accelerated by weather conditions. When the evaporation rate is higher than the bleeding rate the top of the slab surface shrinks due to drying and cracks at the end. They can be up to 3 mm wide at the surface but usually taper quickly over their depth but may penetrate right through a concrete element. Shrinkage Cracking of Concrete Slabs-On-Grade.

Source: inspectapedia.com

Source: inspectapedia.com

When the stress exceed the tensile capacity of the concrete cracks develop. June 2005 D ata sheet. In this tutorial we study the shrinkage effects on a RC slab and the risk of cracking by considering three different approaches. This amount of steel controls cracking if its placed near the top of the slab with 3 4 to 1 inch of cover. 1 Department of Civil.

Source: mdpi.com

Source: mdpi.com

They can be up to 3 mm wide at the surface but usually taper quickly over their depth but may penetrate right through a concrete element. Shrinkage Cracking of Concrete Slabs-On-Grade. Thin members with a large surface area such as slabs are particularly vulnerable. Uncontrolled shrinkage cracking The time at which shrinkage cracks occur depends on the rate of drying but is usually several months to three or four years after casting. Expansion results as steel is converted to iron oxide through corrosion.

Source: researchgate.net

Source: researchgate.net

This amount of steel controls cracking if its placed near the top of the slab with 3 4 to 1 inch of cover. This excess water or water of convenience. When the stress exceed the tensile capacity of the concrete cracks develop. Plastic shrinkage cracks in concrete slabs. Drying shrinkage alone is influenced by many factors - watercement ratio.

Source: forconstructionpros.com

Source: forconstructionpros.com

Expansion results as steel is converted to iron oxide through corrosion. Upon noticing a crack in your concrete slab the first assumption is how there would be a severe problem that needs. Uncontrolled shrinkage cracking The time at which shrinkage cracks occur depends on the rate of drying but is usually several months to three or four years after casting. As an example where concrete pumps are involved and the operators are inexperienced they may add extra water through the line especially if its been held up for long. When concrete is placed.

Source: constrofacilitator.com

Source: constrofacilitator.com

Discussed below are different types of cracks that may occur in concrete slab pavement. Shrinkage Cracking of Concrete Slabs-On-Grade. In the laboratory drying shrinkage tests are the most easily and most frequently performed tests in relation to shrinkagecracking problems. Drying shrinkage alone is influenced by many factors - watercement ratio. Thin members with a large surface area such as slabs are particularly vulnerable.

Source: mdpi.com

Source: mdpi.com

This excess water or water of convenience. It is caused by a combination of factors such as. They can be up to 3 mm wide at the surface but usually taper quickly over their depth but may penetrate right through a concrete element. If the shrinkage movement is opposed by some external or internal restraint stresses will develop. By definition plastic shrinkage cracking occurs while the concrete is still plastic and typically while the slab is still being finished.

Source: reocrete.com.au

Source: reocrete.com.au

If the shrinkage movement is opposed by some external or internal restraint stresses will develop. These cracks form a weakness in the concrete and will be widened andor extended by subsequent drying shrinkage and thermal movement. Too much water results in shrinkage cracks as the concrete cures. Commentary Provision R2431 of ACI 318-19 discusses flexural reinforcement for one-way slabs and beams. Synthetic fibers can help prevent plastic shrinkage cracking as can fogging to reduce evaporation.

Source: buyersask.com

Source: buyersask.com

1nonlinear structural analysis with time steps shrinkage development with time and mechanical properties considered through the equations of EC2 available in Diana. Expansion results as steel is converted to iron oxide through corrosion. Shrinkage-compensating concrete is used to minimize cracking and structural movement caused by drying shrinkage in concrete. Uncontrolled shrinkage cracking The time at which shrinkage cracks occur depends on the rate of drying but is usually several months to three or four years after casting. When the evaporation rate is higher than the bleeding rate the top of the slab surface shrinks due to drying and cracks at the end.

![]() Source: sinaiconstruction.net

Source: sinaiconstruction.net

When concrete is placed. Control joints are designed cuts that go at least half-way through the thickness of the concrete slab. Drying shrinkage alone is influenced by many factors - watercement ratio. Crack in concrete slab Sometimes depending on the necessity the aggregates added in the concrete have low shrinkage. They expand when they absorb the moisture and shrink when they dry.

Source: homeguides.sfgate.com

Source: homeguides.sfgate.com

June 2005 D ata sheet. 1 Department of Civil. Thin members with a large surface area such as slabs are particularly vulnerable. Synthetic fibers can help prevent plastic shrinkage cracking as can fogging to reduce evaporation. It is caused by a combination of factors such as.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site convienient, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title shrinkage cracking in concrete slab by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.