Your Precast concrete wall panels connection details pdf images are ready in this website. Precast concrete wall panels connection details pdf are a topic that is being searched for and liked by netizens now. You can Download the Precast concrete wall panels connection details pdf files here. Download all royalty-free photos and vectors.

If you’re searching for precast concrete wall panels connection details pdf images information linked to the precast concrete wall panels connection details pdf keyword, you have pay a visit to the right site. Our website frequently provides you with suggestions for downloading the highest quality video and image content, please kindly search and find more informative video content and images that match your interests.

Precast Concrete Wall Panels Connection Details Pdf. Precast concrete shear wall structures on the other hand are significantly different in terms of expected structural behavior. What is a Precast Concrete Sandwich Wall Panel. I II and III Bauverlag GMBH 1971. An air space is maintained between the precast exteri-or and the interior wall.

Pdf Panel Connection Details In Existing New Zealand Precast Concrete Buildings From researchgate.net

Pdf Panel Connection Details In Existing New Zealand Precast Concrete Buildings From researchgate.net

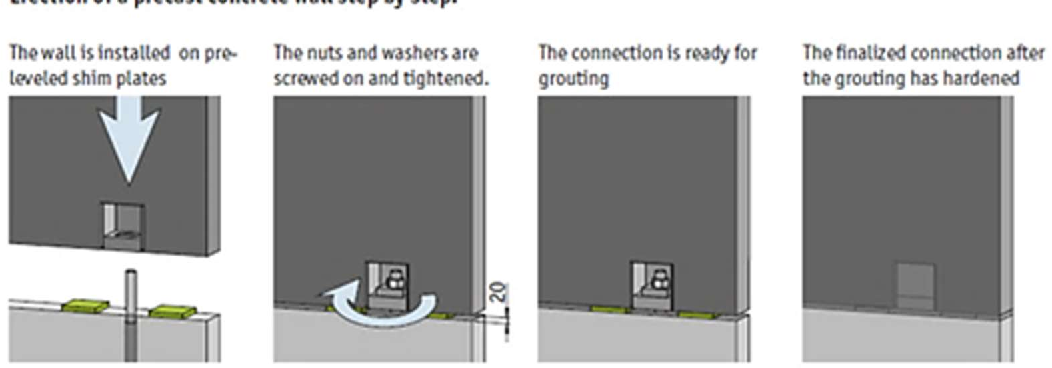

Connection details - Anticipate erection sequence to minimize move-ins. The main function of the precast walls is to speed up the construction process. Some of the advantages of using precast concrete member include. Read PDF Precast Concrete Shear Wall Connections Used For Lyiedium Behaviour of Horizontal Connections for Precast Concrete Load-bearing Shear Wall Panels Subjected to Large Reversed Cyclic Deformations Design and Typical Details of Connections for Precast and Prestressed Concrete This second edition of Precast Concrete Structures introduces the. File Type PDF Koncz T Manual Of Precast Concrete Construction Free In Koncz T Manual of precast concrete construction Vols. Nut-Type Slotted Tie-back Connection with Threaded Rod.

INTRODUCTION Precast concrete elements are commonly used in New Zealand to construct structural members such beams columns wall panels and floor diaphragms.

Wall Panel Connection Details WL13 Panel edge head of man door top view WL14 Panel edge head of man door side view WL15 Panel edge window sill on exterior panels WL16 Door jam OH. PRECAST CONCRETE PANEL CURTAIN WALL AIR BARRIERS AND SEALANTS ATTACHMENT SYSTEMS CASE STUDY BUILDINGS RAIN PENETRATION AND MOISTURE CONTROL SYSTEM JOINTS AND CONNECTIONS SYSTEMS COMPARISIONS THERMAL INSULATION AND R VALUES A typical detail of a precast concrete curtain wall on a site cast concrete frame. Ad Use In Commercial Residential Retail Spaces. When precast concrete wall panels are used in cavity wall designs they will normally serve as the rain barrier. File Type PDF Koncz T Manual Of Precast Concrete Construction Free In Koncz T Manual of precast concrete construction Vols. Precast concrete shear wall structures on the other hand are significantly different in terms of expected structural behavior.

Source: precast.org

Source: precast.org

Handcrafted in the USA. Connection details standard precast components production fixtures and the basic framing concepts of many precast building systems reflect this history to some degree. Ad Use In Commercial Residential Retail Spaces. Although the focus is on precast wall panels produced in established precasting plants site precasting is an option that has been used successfully. Production of clients panels are based on plant loading at the time of award.

Source: pcigulfsouth.org

Source: pcigulfsouth.org

Wall panel details are provided in PDF format. Precast concrete wall buildings represent a significant portion of the New Zealand building. Panel Design Connection Details. 1 minute Precast concrete walls are constructed by casting concrete in a reusable wall mold or form which is then cured in a controlled environment transported to the construction site and lifted into place. An air space is maintained between the precast exteri-or and the interior wall.

Source: researchgate.net

Source: researchgate.net

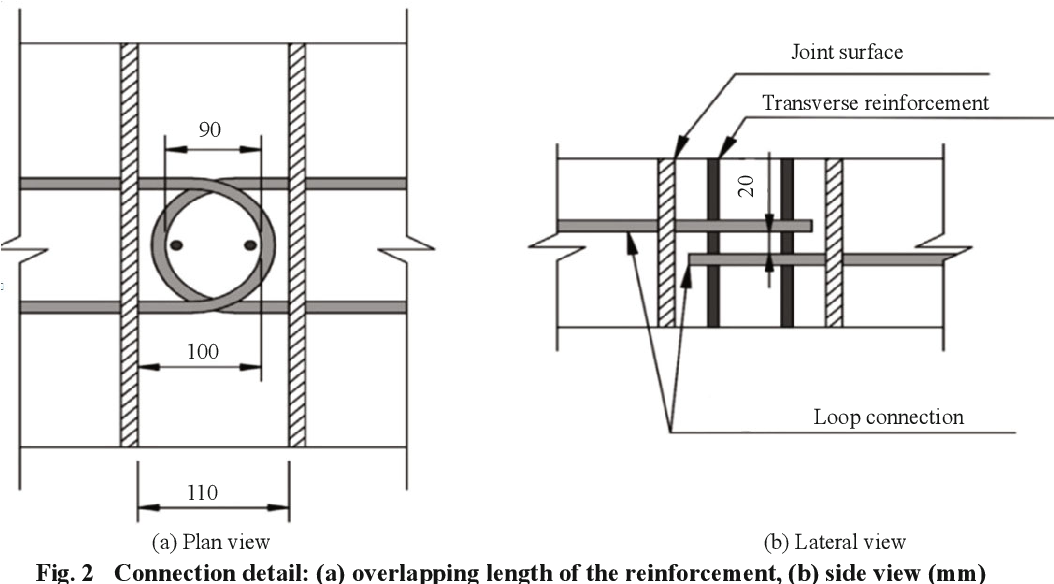

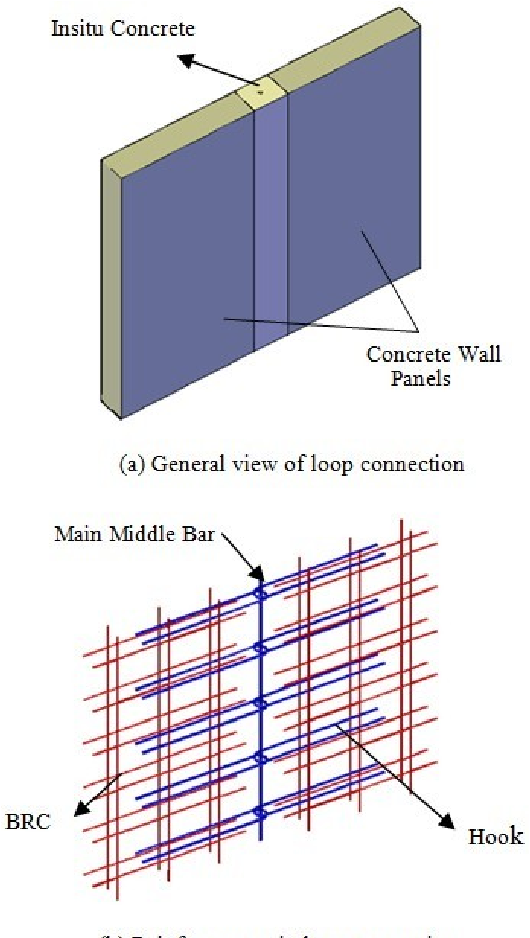

3 Connection Details 142 Waterproofing External joints shall be sealed with baker rods and sealants after filling the joints with grout to avoid the leakage. Erection of Precast Concrete Wall. Wall panel details are provided in PDF format. In some cases precast panels are used as formwork for cast-in-place concrete. Great for Fireplaces Backsplash and Feature Walls.

Source: researchgate.net

Source: researchgate.net

Connection details standard precast components production fixtures and the basic framing concepts of many precast building systems reflect this history to some degree. Ad Use In Commercial Residential Retail Spaces. The main function of the precast walls is to speed up the construction process. 3 Connection Details 142 Waterproofing External joints shall be sealed with baker rods and sealants after filling the joints with grout to avoid the leakage. Wall Panel Connection Details WL13 Panel edge head of man door top view WL14 Panel edge head of man door side view WL15 Panel edge window sill on exterior panels WL16 Door jam OH.

INTRODUCTION Precast concrete elements are commonly used in New Zealand to construct structural members such beams columns wall panels and floor diaphragms. Precastprestressed concrete sandwich wall panels are composed of two concrete wythes layers separated by a layer of rigid foam plastic insulation. Precast building systems most widely used in the United States evolved at a time and in regions where seismic resistance was not a signifi cant design objective. Although the focus is on precast wall panels produced in established precasting plants site precasting is an option that has been used successfully. Wall panel to wall panel Wall panel to Slab Fig.

Source: semanticscholar.org

Source: semanticscholar.org

Bridge Design - PCI Our precast concrete retaining wall blocks play a central role in the retaining walls that we design and manufacture. Precast concrete shear wall panels provide a lateral load-resisting system when combined with the diaphragm action of the floor construction. Connections for Precast Shear Wall PanelsBehaviour of Horizontal Connections for Precast Concrete Load-bearing Shear Wall Panels Subjected to Large Reversed Cyclic DeformationsDesign and Construction of Large-panel Concrete StructuresDesign and Typical Details of Connections for Precast. Panel Design Connection Details. Tilt-up concrete as discussed in ACI 5511R-05 is.

Source: researchgate.net

Source: researchgate.net

Handcrafted in the USA. Connections for Precast Shear Wall PanelsBehaviour of Horizontal Connections for Precast Concrete Load-bearing Shear Wall Panels Subjected to Large Reversed Cyclic DeformationsDesign and Construction of Large-panel Concrete StructuresDesign and Typical Details of Connections for Precast. Precastprestressed concrete sandwich wall panels are composed of two concrete wythes layers separated by a layer of rigid foam plastic insulation. Because precast panels are manufactured well in advance of installation they are ready for transportation to the job site at a moments notice. Non-bearing wall details strap connection at starter joist typical 4.

Source: researchgate.net

Source: researchgate.net

Although the focus is on precast wall panels produced in established precasting plants site precasting is an option that has been used successfully. Erection of Precast Concrete Wall. Connection details standard precast components production fixtures and the basic framing concepts of many precast building systems reflect this history to some degree. Nut-Type Slotted Tie-back Connection with Threaded Rod. A cavity wall Fig.

PRECAST CONCRETE PANEL CURTAIN WALL AIR BARRIERS AND SEALANTS ATTACHMENT SYSTEMS CASE STUDY BUILDINGS RAIN PENETRATION AND MOISTURE CONTROL SYSTEM JOINTS AND CONNECTIONS SYSTEMS COMPARISIONS THERMAL INSULATION AND R VALUES A typical detail of a precast concrete curtain wall on a site cast concrete frame. Joist bearing wall details continuous ledge angle Pmax 12 kips pockets when required roof and panel module should be the same 3. Connection details standard precast components production fixtures and the basic framing concepts of many precast building systems reflect this history to some degree. Precast concrete shear wall panels provide a lateral load-resisting system when combined with the diaphragm action of the floor construction. As such different design philosophies have been developed for precast structures in the USA 1 2 where precast concrete structural systems fall.

Source: pinterest.com

Source: pinterest.com

Door 1 WL17 Door jam OH. INTRODUCTION Precast concrete elements are commonly used in New Zealand to construct structural members such beams columns wall panels and floor diaphragms. Door 1 WL17 Door jam OH. Wall Panel Connection Details WL13 Panel edge head of man door top view WL14 Panel edge head of man door side view WL15 Panel edge window sill on exterior panels WL16 Door jam OH. Ning designing fabrication and erecting precast concrete wall panels.

Because precast panels are manufactured well in advance of installation they are ready for transportation to the job site at a moments notice. Joist bearing wall details continuous ledge angle Pmax 12 kips pockets when required roof and panel module should be the same 3. Some of the advantages of using precast concrete member include. Twenty seven panels utilizing different connection details were tested in the out-of-plane direction to determine the performance of the panel to foundation connection. Tilt-up concrete as discussed in ACI 5511R-05 is.

Source: semanticscholar.org

Source: semanticscholar.org

1 Precast Concrete Elements Wall Panels Parapet Beams Staircase Hollow core slab Pod Element. 1 The components can resist ultimate design loads in a. PRECAST CONCRETE PANEL CURTAIN WALL AIR BARRIERS AND SEALANTS ATTACHMENT SYSTEMS CASE STUDY BUILDINGS RAIN PENETRATION AND MOISTURE CONTROL SYSTEM JOINTS AND CONNECTIONS SYSTEMS COMPARISIONS THERMAL INSULATION AND R VALUES A typical detail of a precast concrete curtain wall on a site cast concrete frame. INTRODUCTION Precast concrete elements are commonly used in New Zealand to construct structural members such beams columns wall panels and floor diaphragms. One of the concrete wythes may be a standard shape such as a flat slab hollow-core section double tee or any custom architectural concrete section.

Source: semanticscholar.org

Source: semanticscholar.org

Because precast panels are manufactured well in advance of installation they are ready for transportation to the job site at a moments notice. Nut-Type Slotted Tie-back Connection with Threaded Rod. File Type PDF Koncz T Manual Of Precast Concrete Construction Free In Koncz T Manual of precast concrete construction Vols. Handcrafted in the USA. An air space is maintained between the precast exteri-or and the interior wall.

Source: researchgate.net

Source: researchgate.net

3 Connection Details 142 Waterproofing External joints shall be sealed with baker rods and sealants after filling the joints with grout to avoid the leakage. Erection of Precast Concrete Wall. As such different design philosophies have been developed for precast structures in the USA 1 2 where precast concrete structural systems fall. Ning designing fabrication and erecting precast concrete wall panels. Precastprestressed concrete sandwich wall panels are composed of two concrete wythes layers separated by a layer of rigid foam plastic insulation.

Source: semanticscholar.org

Source: semanticscholar.org

The four rules for satisfactory joint design are that. PRECAST CONCRETE PANEL CURTAIN WALL AIR BARRIERS AND SEALANTS ATTACHMENT SYSTEMS CASE STUDY BUILDINGS RAIN PENETRATION AND MOISTURE CONTROL SYSTEM JOINTS AND CONNECTIONS SYSTEMS COMPARISIONS THERMAL INSULATION AND R VALUES A typical detail of a precast concrete curtain wall on a site cast concrete frame. Erection of Precast Concrete Wall. Connection details standard precast components production fixtures and the basic framing concepts of many precast building systems reflect this history to some degree. In some cases precast panels are used as formwork for cast-in-place concrete.

Source: semanticscholar.org

Source: semanticscholar.org

Precast concrete shear wall panels provide a lateral load-resisting system when combined with the diaphragm action of the floor construction. The effectiveness of precast concrete shear walls is largely dependent on the panel-to-panel connections. 341 is the most effective wall for the optimum separa-tion and control of both outside and in-side air and humidity conditions. AutoCAD drawings are available upon request. Research and application of the precast concrete beam-to-beam connection details have published since 1975.

Source: researchgate.net

Source: researchgate.net

1 Precast Concrete Elements Wall Panels Parapet Beams Staircase Hollow core slab Pod Element. Bridge Design - PCI Our precast concrete retaining wall blocks play a central role in the retaining walls that we design and manufacture. 3 Connection Details 142 Waterproofing External joints shall be sealed with baker rods and sealants after filling the joints with grout to avoid the leakage. 4 Types Of Precast Connections. Erection of Precast Concrete Wall.

Source: pcigulfsouth.org

Source: pcigulfsouth.org

Research and application of the precast concrete beam-to-beam connection details have published since 1975. 4 Types Of Precast Connections. Some of the advantages of using precast concrete member include. The effectiveness of precast concrete shear walls is largely dependent on the panel-to-panel connections. 1 The components can resist ultimate design loads in a.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site good, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title precast concrete wall panels connection details pdf by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.