Your Polished concrete floor mix ratio images are available in this site. Polished concrete floor mix ratio are a topic that is being searched for and liked by netizens today. You can Get the Polished concrete floor mix ratio files here. Find and Download all royalty-free vectors.

If you’re searching for polished concrete floor mix ratio pictures information related to the polished concrete floor mix ratio keyword, you have pay a visit to the ideal site. Our site always provides you with hints for seeking the maximum quality video and picture content, please kindly search and find more informative video content and images that fit your interests.

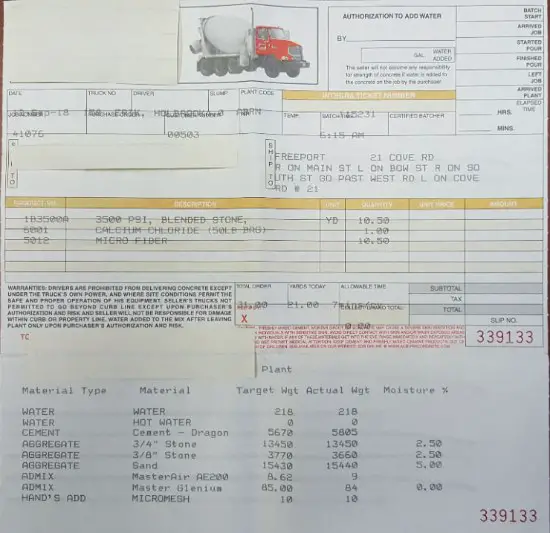

Polished Concrete Floor Mix Ratio. Do not add air to the concrete if at all possible. Between 3500 and 5000 is preferred for polished concrete. Do not use air entrainment or at least hold to a maximum of 3 percent. More ingredients can be added if the consistency is still not quite right.

Concrete Screed Concrete Screed Differences Becosan From becosan.com

Concrete Screed Concrete Screed Differences Becosan From becosan.com

Concrete is made by combining cement gravel sand and water. Do not use calcium chloride accelerators as they can interfere with acid stains and densifiers. If you have hired the services of a professional concrete supplier they can take care of the mixing process for you. Use a minimum 3500 PSI mix. Curing compounds should be avoided. They are most commonly 100mm thick.

Concrete is not considered polished before 400 grit.

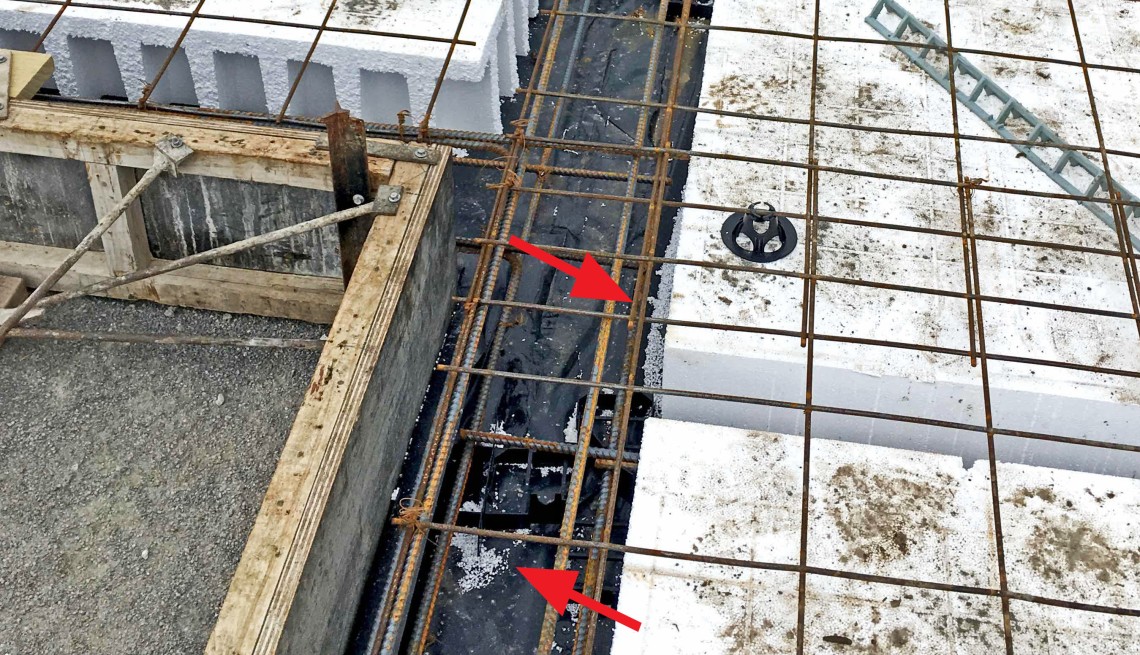

Surfaces must register SCOF. If you feel the need to have air-entrained concrete try not to exceed 3. Polished concrete flooring is simply a concrete floor that has been treated with a chemical densifier to fill in the holespores and ground down similar to sanding wood with progressively finer grinding tools. But even if you get the ratio right the type of sand and aggregate you use will also impact the appearance of your floor. The mixture is then usually poured onto a steel and fibre-reinforced mesh which minimises the risk of cracking. Any admixtures plasticizers or anything taking the place of Portland-based cement shall be kept to a minimum.

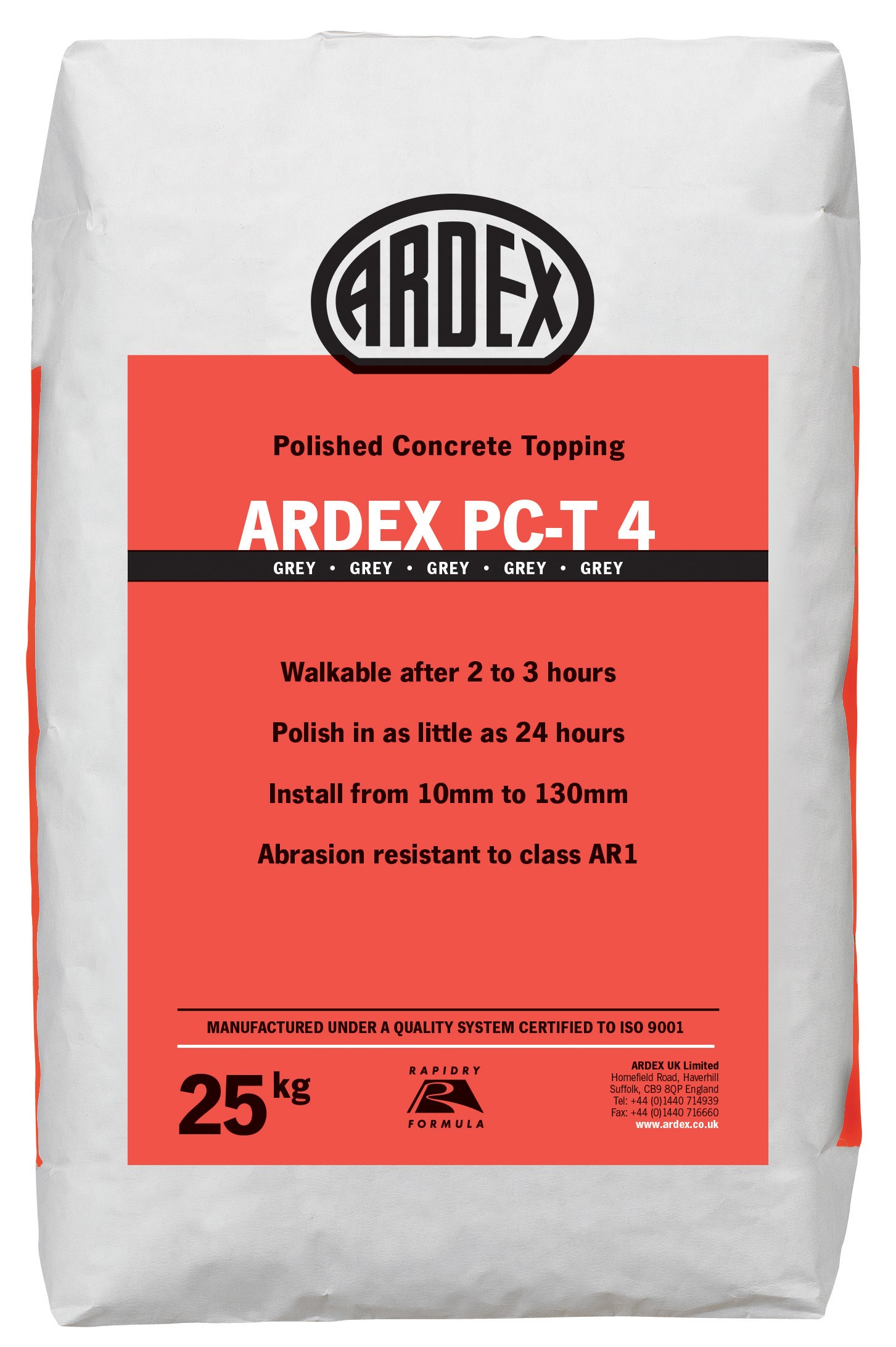

Source: ardex.co.uk

Source: ardex.co.uk

To make this mix youll need to combine 1 part cement powder 3 parts sand and 2 parts washed aggregate. Lightweight aggregates should be avoided as they can crack and spall during the process. Either way it will then be levelled and compacted using internal or external. Any admixtures plasticizers or anything taking the place of Portland-based cement shall be kept to a minimum. Slab and Mix Design.

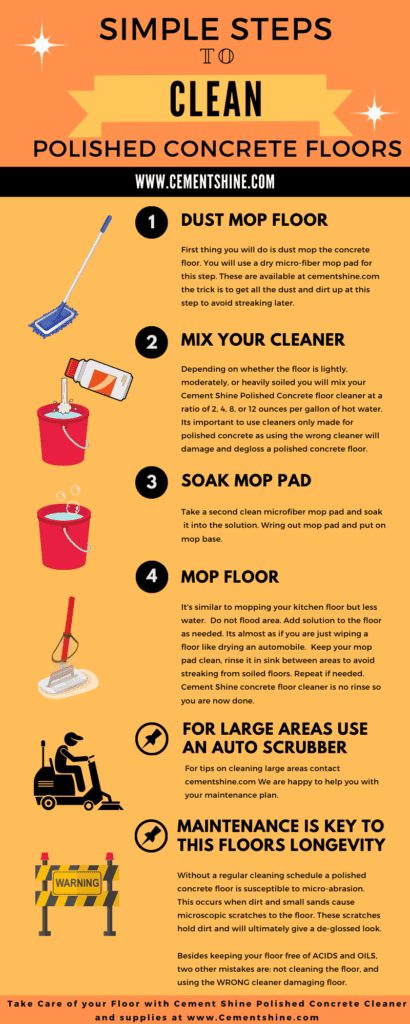

Source: zeraus.com

Source: zeraus.com

Its method NFSI 101-A Standard for Evaluating High-traction Flooring Materials Coatings and Finishes tests treated surfaces twice. Surfaces must register SCOF. Use for interior floors only Can be used as pinhole filler for ARDEX PC-TTM Polished Concrete Topping 2012 ARDEX LP. Do not use air entrainment or at least hold to a maximum of 3 percent. Air entrainment should be avoided as it can cause the surface to spall and delaminate.

Source: concretepolishinghouston.com

Source: concretepolishinghouston.com

Its method NFSI 101-A Standard for Evaluating High-traction Flooring Materials Coatings and Finishes tests treated surfaces twice. Use a minimum 3500 PSI mix. 3000 PSI is normal for concrete driveways concrete sidewalks and patios. Its method NFSI 101-A Standard for Evaluating High-traction Flooring Materials Coatings and Finishes tests treated surfaces twice. The producers of structural aggregate dont need to worry about color consistency or aggregate appearance.

Source: constructionspecifier.com

Source: constructionspecifier.com

This concrete mix ratio of aggregate to sand to cement is an important factor in determining the compressive strength of the concrete mixture. It might sound simple but we cant understate the amount of thought and science that goes into creating the perfect polished concrete flooring mix. Architectural concrete requires Class 5 material at least. 5000 psi Concrete Mix Ratio When working to achieve a 5000 psi or higher concrete mix you should consult with a professional before commencing. Unfortunately it is the most overlooked factor contributing to many disappointments.

Source: cresco-group.com

Source: cresco-group.com

And 30 days later to evaluate the effects of normal facility traffic on the original reading. Polished concrete flooring is simply a concrete floor that has been treated with a chemical densifier to fill in the holespores and ground down similar to sanding wood with progressively finer grinding tools. What is the best concrete mix ratio. In order to acquire high-strength properties water affects the strength of concrete to a large extent. Curing compounds should be avoided.

Source: renobuild.ie

Source: renobuild.ie

Slabs should be cured with. Its method NFSI 101-A Standard for Evaluating High-traction Flooring Materials Coatings and Finishes tests treated surfaces twice. Confirm there is NO Slag or Fly Ash in the mix as these materials will. Dos and donts of mix design for polished concrete. Between 3500 and 5000 is preferred for polished concrete.

Source: fenixfinish.com

Source: fenixfinish.com

Tester of floors including polished concrete. Its normal value lies between 04 to 06 as per IS code 10262 2009 for nominal mixes. 3000 PSI is normal for concrete driveways concrete sidewalks and patios. Use for interior floors only Can be used as pinhole filler for ARDEX PC-TTM Polished Concrete Topping 2012 ARDEX LP. Any admixtures plasticizers or anything taking the place of Portland-based cement shall be kept to a minimum.

Source: cresco-group.com

Source: cresco-group.com

Once soon after a floor is polished and densified. Avoid these practices for what is really architectural concrete. Theyre designed with structural integrity in mind so your polished concrete surface will hold its shape for decades to come. Polished concrete flooring is simply a concrete floor that has been treated with a chemical densifier to fill in the holespores and ground down similar to sanding wood with progressively finer grinding tools. Lightweight aggregates should be avoided as they can crack and spall during the process.

Source: everything-about-concrete.com

Source: everything-about-concrete.com

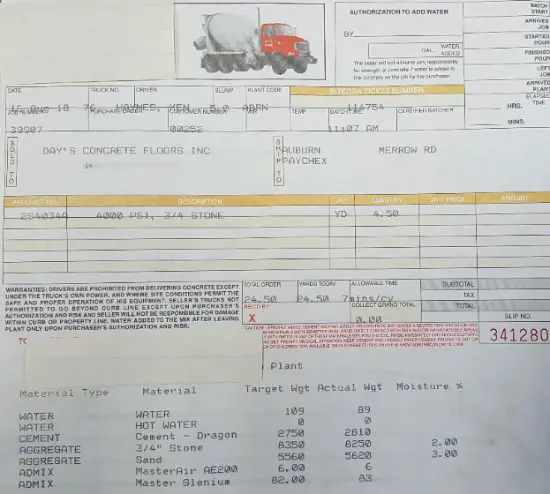

A wc ratio of 0040 and 5-12 sack specification with 900 to 1000 kg 2000 to 2200 lb of aggregate and six per cent air with welded wire reinforcement is a durable exterior mix design but this concrete is stiff and may need a water-reducer to aid placement. More ingredients can be added if the consistency is still not quite right. To make this mix youll need to combine 1 part cement powder 3 parts sand and 2 parts washed aggregate. Concrete is not considered polished before 400 grit. Slab and Mix Design.

Source: alibaba.com

Source: alibaba.com

Do not use calcium chloride accelerators as they can interfere with acid stains and densifiers. It might sound simple but we cant understate the amount of thought and science that goes into creating the perfect polished concrete flooring mix. If you feel the need to have air-entrained concrete try not to exceed 3. The proper concrete mixing ratios are 123 133 124 for cement sand and stone. The normal concrete mix ratio is 5 to 1 to 5 sand cement and aggregate.

Source: self-build.co.uk

Source: self-build.co.uk

Coarse aggregates for concrete slabs When mixing its important that the concrete is placed within half an hour to ensure consistency and easy placement. Tester of floors including polished concrete. This is especially true if your concrete will eventually be load-bearing in nature. If you feel the need to have air-entrained concrete try not to exceed 3. Any admixtures plasticizers or anything taking the place of Portland-based cement shall be kept to a minimum.

Source: renobuild.ie

Source: renobuild.ie

The producers of structural aggregate dont need to worry about color consistency or aggregate appearance. Architectural concrete requires Class 5 material at least. The normal concrete mix ratio is 5 to 1 to 5 sand cement and aggregate. Concrete is not considered polished before 400 grit. Do not add air to the concrete if at all possible.

Source: wikiwand.com

Source: wikiwand.com

Polished concrete floors are best designed in early on in a project. Unfortunately it is the most overlooked factor contributing to many disappointments. Air entrainment should be avoided as it can cause the surface to spall and delaminate. Mix Designs and Polished Concrete Concrete that will be ground and polished benefits from having a larger coarse aggregate content than conventional structural concrete. It might sound simple but we cant understate the amount of thought and science that goes into creating the perfect polished concrete flooring mix.

Source: concretedecor.net

Source: concretedecor.net

Its method NFSI 101-A Standard for Evaluating High-traction Flooring Materials Coatings and Finishes tests treated surfaces twice. Use a minimum 3500 PSI mix. 5000 psi Concrete Mix Ratio When working to achieve a 5000 psi or higher concrete mix you should consult with a professional before commencing. Coarse aggregates for concrete slabs When mixing its important that the concrete is placed within half an hour to ensure consistency and easy placement. AT358 ENG 0112 Technical Data According to ARDEX Quality Standards All data based on a mixing ratio of 25 parts powder to 1 part water by volume at 70F 21C.

Source: wikiwand.com

Source: wikiwand.com

The ratios are tirelessly tested and specifically engineered for optimum performance. Polished concrete floors are best designed in early on in a project. Your finish will not be as tight or reflective air will not polish and air-entrained concrete has lower compressive strength. Mixing ratios are based on what psi concrete you need. Generally the mix proportion for cement concrete floor finish used as cement concrete 124 1 part of cement 2 parts of fine aggregate and 4 parts of coarse aggregate.

Source: everything-about-concrete.com

Source: everything-about-concrete.com

Concrete Mixture shall be 3000 PSI or higher non-air entrained. Coarse aggregates for concrete slabs When mixing its important that the concrete is placed within half an hour to ensure consistency and easy placement. Higher watercement ratios can lead to a weak surface layer. It might sound simple but we cant understate the amount of thought and science that goes into creating the perfect polished concrete flooring mix. Its method NFSI 101-A Standard for Evaluating High-traction Flooring Materials Coatings and Finishes tests treated surfaces twice.

Source: pinterest.com

Source: pinterest.com

Architectural concrete requires Class 5 material at least. Polished concrete flooring is simply a concrete floor that has been treated with a chemical densifier to fill in the holespores and ground down similar to sanding wood with progressively finer grinding tools. It might sound simple but we cant understate the amount of thought and science that goes into creating the perfect polished concrete flooring mix. This should be done using a. Well go into the ins and outs of mix ratios in more detail below but to simplify a good concrete mix ratio for a concrete floor is.

Source: becosan.com

Source: becosan.com

That is a polished concrete floor that works its way to a higher finish over 400 grit for example is. Dos and donts of mix design for polished concrete. To make 1 cubic metre of 15 Mpa concrete you will need to mix 5 12 bags of cement with 075 cubic metres of sand and 075 cubic metres of stone. The ratios are tirelessly tested and specifically engineered for optimum performance. Its method NFSI 101-A Standard for Evaluating High-traction Flooring Materials Coatings and Finishes tests treated surfaces twice.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site convienient, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title polished concrete floor mix ratio by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.