Your How to treat cold joint in concrete images are available. How to treat cold joint in concrete are a topic that is being searched for and liked by netizens now. You can Get the How to treat cold joint in concrete files here. Get all royalty-free photos and vectors.

If you’re searching for how to treat cold joint in concrete pictures information related to the how to treat cold joint in concrete keyword, you have pay a visit to the right site. Our site frequently provides you with suggestions for refferencing the highest quality video and image content, please kindly hunt and find more enlightening video content and graphics that fit your interests.

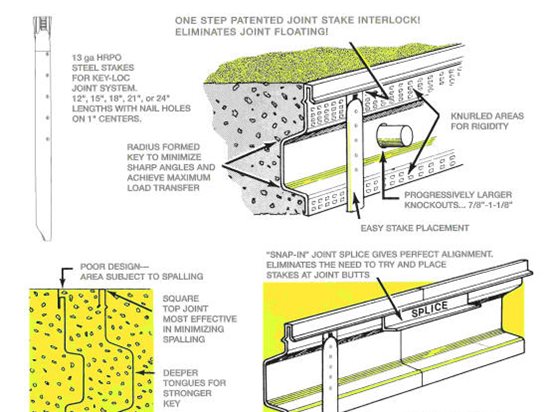

How To Treat Cold Joint In Concrete. Let the rebar run 2 to 3 feet out of the concrete at the joint so you can tie into it when you continue the pour. When the placement consists of several layers concrete delivery should be scheduled so that each layer is placed while the preceding one is still plastic to avoid cold joints. A cold joint occurs due to the inability of freshly poured wet cement to intermingle and bind with an already hardened cement. Ensure that you have steel dowels with enough development length or add proper anchorage.

Cold Pour Joints In Concrete Foundations Floors From inspectapedia.com

Cold Pour Joints In Concrete Foundations Floors From inspectapedia.com

It depends on location of cold joint. A cold joint occurs due to the inability of freshly poured wet cement to intermingle and bind with an already hardened cement. Repairing Cold Joints in Cured Slabs. To avoid cold joints placing should be resumed substantially before the time of initial set. When the placement consists of several layers concrete delivery should be scheduled so that each layer is placed while the preceding one is still plastic to avoid cold joints. Let the rebar run 2 to 3 feet out of the concrete at the joint so you can tie into it when you continue the pour.

For unusually long delays during concreting the concrete should be kept alive by periodically re-vibrating it.

There are many solutions to cold joints few are. For unusually long delays during concreting the concrete should be kept alive by periodically re-vibrating it. High pressure flexible polyurethane injection. The key function of joint sealing is to minimize water ingress and create a secure waterproofing barrier. Superstop is a composite waterstop containing expandable granular bentonite. The seal must be capable of accommodating the anticipated joint opening and closing due to static reasons or temperature changes.

Source: pinterest.com

Source: pinterest.com

Beyond Dicks reply cold joints are normally treated as joints and no special bonding is used. Closing and sealing the cracks prevents water from entering the crack and causing damage through freeze and thaw. Impact of Retarder-Induced Roughness on Shear Friction Capacity using Conventional and High-Strength Reinforcement. Looking For Expert AdviceVisit- httpscementconcreteinabout-er-iqbal-singh-velasaraRead More about Cold Joints- httpscementconcreteincold-joint-. To avoid cold joints placing should be resumed substantially before the time of initial set.

Source: eng-tips.com

Source: eng-tips.com

Ultrasonic testing of concrete is an effective way for quality assessment and uniformity and crack depth estimation. The seal must be capable of accommodating the anticipated joint opening and closing due to static reasons or temperature changes. If there isnt already rebar in place where you stop. Concrete cold joints occur due to many reasons. Closing and sealing the cracks prevents water from entering the crack and causing damage through freeze and thaw.

Source: engineersdaily.com

Source: engineersdaily.com

In this episode of concrete ninja Lawrence shows us how he does his cold joints are cold joint is when you join two different trucks of concrete to Gever. This place must be filled with a rich mortar layer 12 mm in thickness is placed on the cold joint fresh concrete is then placed on the mortar layer and that cold joint is systematically and thoroughly vibrated penetrating the vibrator deep into the old layer of concrete. The seal must be capable of accommodating the anticipated joint opening and closing due to static reasons or temperature changes. Closing and sealing the cracks prevents water from entering the crack and causing damage through freeze and thaw. Looking For Expert AdviceVisit- httpscementconcreteinabout-er-iqbal-singh-velasaraRead More about Cold Joints- httpscementconcreteincold-joint-.

Source: pinterest.com

Source: pinterest.com

It is widely recognized that difficulties in the constructive method of concrete structures can entail cold joints that evidently impair the structural performance since it reduces the systems stress-strain characteristics Harsem 2005. When working with the placement of cement these types of work stoppages or delays can result in the formation of a cold joint. Cold joints tends to failure if the joint is in tension. To avoid cold joints placing should be resumed substantially before the time of initial set. A cold joint is an undesired discontinuity between two layers of concrete.

Source: inspectapedia.com

Source: inspectapedia.com

In this episode of concrete ninja Lawrence shows us how he does his cold joints are cold joint is when you join two different trucks of concrete to Gever. Roughen the surface to a minimum of 6 mm undulations. A Statistical Approach to Refine Design Codes for Interface Shear Transfer in Reinforced Concrete Members. Cold joints tends to failure if the joint is in tension. A cold joint occurs due to the inability of freshly poured wet cement to intermingle and bind with an already hardened cement.

Source: probuilder.com

Source: probuilder.com

Martina Viera March 29 2020. The seal must be capable of accommodating the anticipated joint opening and closing due to static reasons or temperature changes. Martina Viera March 29 2020. It depends on location of cold joint. A If concrete is so green that it can be removed manually and if vibrators can penetrate the surface without much effort fresh.

Source: concretenetwork.com

Source: concretenetwork.com

Repairing Cold Joints in Cured Slabs. Joint sealing solutions are recommended for use in all kinds of construction and joints for waterproofing. Cold joint in concrete due to delayed concrete placing may cause a reduced shear resistance and increased water permeation. A rich mortar layer 12 mm in thickness is placed on the cold joint fresh concrete is then placed on the mortar layer and the joint is thoroughly and systematically vibrated penetrating the vibrator deep into the old layer of concrete. A smooth cold joint of concrete is a weak plane caused by an interruption in the casting process.

Ultrasonic testing of concrete is an effective way for quality assessment and uniformity and crack depth estimation. The key function of joint sealing is to minimize water ingress and create a secure waterproofing barrier. Ensure that you have steel dowels with enough development length or add proper anchorage. When the placement consists of several layers concrete delivery should be scheduled so that each layer is placed while the preceding one is still plastic to avoid cold joints. The seal must be capable of accommodating the anticipated joint opening and closing due to static reasons or temperature changes.

Source: m.youtube.com

Source: m.youtube.com

When the placement consists of several layers concrete delivery should be scheduled so that each layer is placed while the preceding one is still plastic to avoid cold joints. Impact of Retarder-Induced Roughness on Shear Friction Capacity using Conventional and High-Strength Reinforcement. Repairing Cold Joints in Cured Slabs. The high-pressure injection procedure allows the insertion of a liquid into a very narrow crack. In this episode of concrete ninja Lawrence shows us how he does his cold joints are cold joint is when you join two different trucks of concrete to Gever.

![]() Source: civiconcepts.com

Source: civiconcepts.com

Let the rebar run 2 to 3 feet out of the concrete at the joint so you can tie into it when you continue the pour. If it is a matter of preventing water from penetrating the joint then a waterbar or properly designed caulked joint can be used. When the placement consists of several layers concrete delivery should be scheduled so that each layer is placed while the preceding one is still plastic to avoid cold joints. Repairing Cold Joints in Cured Slabs. Ultrasonic testing of concrete is an effective way for quality assessment and uniformity and crack depth estimation.

Source: buyersask.com

Source: buyersask.com

However if the location is not very critical the following may suffice. Let the rebar run 2 to 3 feet out of the concrete at the joint so you can tie into it when you continue the pour. To avoid cold joints placing should be resumed substantially before the time of initial set. A If concrete is so green that it can be removed manually and if vibrators can penetrate the surface without much effort fresh. The high-pressure injection procedure allows the insertion of a liquid into a very narrow crack.

Source: pinterest.com

Source: pinterest.com

The full knitting together of the two batches of concrete under vibration to form a homogeneous mass is therefore not possible unlike the compaction of two. Superstop is used for sealing cold joints in concrete and to prevent water. Ultrasonic Pulse Velocity UPV Ultrasonic Pulse Velocity UPV is an effective non-destructive testing NDT method for quality control of concrete materials and evaluating concrete integrity on or around the cold joint. A cold joint is an undesired discontinuity between two layers of concrete. Concrete cold joints occur due to many reasons.

![]() Source: civiconcepts.com

Source: civiconcepts.com

Repair small cracks at cold joints with thin mix or a concrete crack sealant. Concrete cold joints occur due to many reasons. The full knitting together of the two batches of concrete under vibration to form a homogeneous mass is therefore not possible unlike the compaction of two. JOURNAL Articles ON COLD JOINTS. Placement of concrete should begin in the corners and work toward the center.

Source: pinterest.com

Source: pinterest.com

Beyond Dicks reply cold joints are normally treated as joints and no special bonding is used. The high-pressure injection procedure allows the insertion of a liquid into a very narrow crack. This study presents an analytical model based on the concept of. Cold joints tends to failure if the joint is in tension. A If concrete is so green that it can be removed manually and if vibrators can penetrate the surface without much effort fresh.

Source: pinterest.com

Source: pinterest.com

A cold joint is usually characterized by poor bond unless remedial measures are taken before placing concrete against a previously hardened batch. It depends on location of cold joint. A cold joint is usually characterized by poor bond unless remedial measures are taken before placing concrete against a previously hardened batch. When Cold Joint has Hardened In case the concrete at the joint has become so stiff that it cannot be remoulded and mortar or slurry does not rise in spite. ACIs Guide for Consolidation of Concrete ACI 309R-87 gives the following advice.

Source: inspectapedia.com

Source: inspectapedia.com

The full knitting together of the two batches of concrete under vibration to form a homogeneous mass is therefore not possible unlike the compaction of two. Concrete cold joints occur due to many reasons. Superstop is used for sealing cold joints in concrete and to prevent water. Placement of concrete should begin in the corners and work toward the center. Ultrasonic Pulse Velocity UPV Ultrasonic Pulse Velocity UPV is an effective non-destructive testing NDT method for quality control of concrete materials and evaluating concrete integrity on or around the cold joint.

Source: inspectapedia.com

Source: inspectapedia.com

However if the location is not very critical the following may suffice. Beyond Dicks reply cold joints are normally treated as joints and no special bonding is used. If it is a matter of preventing water from penetrating the joint then a waterbar or properly designed caulked joint can be used. When working with the placement of cement these types of work stoppages or delays can result in the formation of a cold joint. Cold joints are formed primarily between two batches of concrete where the delivery and placement of the second batch has been delayed and the initial placed and compacted concrete has started to set.

Source: probuilder.com

Source: probuilder.com

The high-pressure injection procedure allows the insertion of a liquid into a very narrow crack. Try to avoid cold joints in the middle of the wall where the loads are high. To prevent cold joints in walls beams and other structural components it is necessary to place concrete in layers about 18 inches deep and intermix each layer with the previous one by using a vibrator. There are many solutions to cold joints few are. For unusually long delays during concreting the concrete should be kept alive by periodically re-vibrating it.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site value, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title how to treat cold joint in concrete by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.