Your How to prepare a concrete floor for epoxy coating images are ready. How to prepare a concrete floor for epoxy coating are a topic that is being searched for and liked by netizens now. You can Download the How to prepare a concrete floor for epoxy coating files here. Download all free photos and vectors.

If you’re looking for how to prepare a concrete floor for epoxy coating images information related to the how to prepare a concrete floor for epoxy coating interest, you have pay a visit to the ideal site. Our website always gives you hints for seeking the highest quality video and image content, please kindly surf and locate more enlightening video content and images that fit your interests.

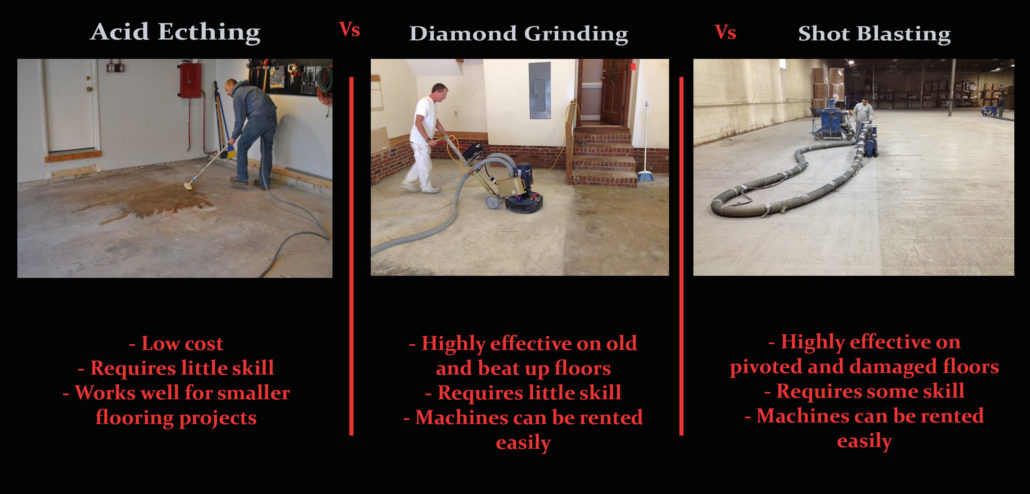

How To Prepare A Concrete Floor For Epoxy Coating. Use a heat resistant scraper to carefully remove the resin from the tile surface. All these methods are used to prep the floors before applying Epoxy but the most used are Diamond Grinding and Shot Blasting. To avoid the costly problems that can happen after installing coatings there are two crucial steps you must take. There are three main ways to prepare concrete for epoxy.

Applying Epoxy On Rough Concrete 3 Useful Tips From learncoatings.com

Applying Epoxy On Rough Concrete 3 Useful Tips From learncoatings.com

Determine if moisture or dampness is coming up through the concrete from the ground. The absolute first step before applying your epoxy coating is to prep your floor. When working on a concrete base you should look to fill in any cracks hairline fractures joints and divots that may be exposed. Expose the area to heat for about 60 seconds or until the coating has softened. Acid etching The acid etching process is extremely DIY in nature. If youre working on a concrete base fill in any cracks or patch areas that need care before you start to clean.

Chemical stripping uses solvents that can remove thin layers of dirt and grease.

Once you are finished with these 7 steps your floor should be fully prepped and ready for your epoxy coating. Use a heat resistant scraper to carefully remove the resin from the tile surface. Shot blasting is a process in which special equipment is used to help prepare the concrete or cement before epoxy paint can be applied. Unlike the other two techniques acid etching doesnt require much skill or machinery. It is also the surest way to risk floor finish failure. 3 Main Garage Floor Prep Options Acid Etching.

Source: youtube.com

Source: youtube.com

Leave the plastic in place for at least 24 hours before checking for condensation. The absolute first step before applying your epoxy coating is to prep your floor. It is important to prepare a cement floor before applying an epoxy coating to ensure that the epoxy will last longer. Extreme heat softens the resin making it easier to remove. 30 drying days for each inch of slab thickness.

Source: thomasnet.com

Source: thomasnet.com

Professionals use two methods of preparing the surface acid washing and machine grinding. This method is the most DIY friendly and doesnt require any heavy machinery as the other methods do for your concrete floor. There are several ways to prepare concrete for epoxy coating. Acrylic coatings are made up of acrylic resin and a. Any cracks or concrete spall should be filled and stabilized before a new epoxy coating is applied.

Source: onedaycustomfloors.com

Source: onedaycustomfloors.com

Previous coatings or paints should be removed before a new epoxy coating is applied. If relative humidity is greater than 75 a moisture. In some cases where plant conditions allow a stripper may be. There are primarily three ways to prepare your garage or concrete floor for epoxy application. 3 Main Garage Floor Prep Options Acid Etching.

Source: learncoatings.com

Source: learncoatings.com

When it comes to creating the perfect epoxy floor surface preparation is the single most important step to ensuring the longevity of the floor. The preferred method for concrete surface preparation in most cases is grinding of all horizontal surfaces. In some cases where plant conditions allow a stripper may be. Only trained professionals use this. Shot-blasting is another good method for mechanically abrading concrete to receive a coating and is typically recommended for heavier duty epoxy mortars or urethane cement systems.

Source: florock.net

Source: florock.net

If youre working on a concrete base fill in any cracks or patch areas that need care before you start to clean. When the surface preparation process has been completed you have to. This method is the most DIY friendly and doesnt require any heavy machinery as the other methods do for your concrete floor. The first step before applying any epoxy coating is to prep the floor. If moisture is evident your floor isnt suitable for epoxy.

Source: pinterest.com

Source: pinterest.com

Acrylic coatings are made up of acrylic resin and a. Your concrete floor wont be able to accept the new coating if the concrete is too damp. Chemical Stripping Cleaning. This will also remove dust salts and other particles that can affect your epoxy coating process. Ensure you measure the moisture condition inside the concrete slab before the application begins.

Source: pinterest.com

Source: pinterest.com

When working on a concrete base you should look to fill in any cracks hairline fractures joints and divots that may be exposed. Previous coatings or paints should be removed before a new epoxy coating is applied. The first and best epoxy preparation is to allow concrete slabs sufficient time to fully dry in the first place. Leave the plastic in place for at least 24 hours before checking for condensation. This method is the most DIY friendly and doesnt require any heavy machinery as the other methods do for your concrete floor.

Source: resin-expert.com

Source: resin-expert.com

It is also the surest way to risk floor finish failure. Preparation for Decorative Acrylic Coatings. Shot blasting is a process in which special equipment is used to help prepare the concrete or cement before epoxy paint can be applied. Use a wet vacuum and dry the surface to get rid of the water used in rinsing. When applying directly to the substrate the surface should be at least as rough as a 200-300 grit grindsand.

Source: thermalchem.com

Source: thermalchem.com

Resinous floors bond best to a surface that has a sandpaper-like finish. You will need to tape a large piece of plastic over a section of the floor being certain to seal all of the edges to the concrete using duct tape. When applying directly to the substrate the surface should be at least as rough as a 200-300 grit grindsand. Use a pressure washer preferably or a wet vacuum to thoroughly clean the floor. The process begins with applying an acid solution to the floor.

Source: youtube.com

Source: youtube.com

Since chemical stripping is labour intensive and creates chemical waste that needs disposal it isnt a very common approach with commercial projects. When the surface preparation process has been completed you have to. Use a heat resistant scraper to carefully remove the resin from the tile surface. All these methods are used to prep the floors before applying Epoxy but the most used are Diamond Grinding and Shot Blasting. Best Way To Prepare Concrete Floor For Epoxy Bonding.

Source: pinterest.com

Source: pinterest.com

If there is water on the plastic you will need to. Epoxies as a general rule will not fix a floor so any issues such as small holes cracks and dings in the floor should be. Use a heat gun to warm up the surface that has epoxy stains or a layer of epoxy paint. There are three main ways to prepare concrete for epoxy. The purpose is to restore the smoothness of the surface and make it even for proper application of epoxy.

Source: oneprojectcloser.com

Source: oneprojectcloser.com

You will need to tape a large piece of plastic over a section of the floor being certain to seal all of the edges to the concrete using duct tape. The purpose is to restore the smoothness of the surface and make it even for proper application of epoxy. 1existing epoxy floor coating is peeling up or showing other signs of delemination 2Do not attempt to apply epoxy over existing concrete sealers. Professionals use two methods of preparing the surface acid washing and machine grinding. There are several ways to prepare concrete for epoxy coating.

Source: thermalchem.com

Source: thermalchem.com

It will keep the coating looking brand new for as long as possible and eliminate the possibility of the coating peeling. Decorative acrylic coatings dont require porosity like reactive penetrating sealers but they do require that the surface profile is rough enough for adhesion. Preparing a concrete floor for AeroMarine Products epoxy coating. WHEN NOT TO APPLY EPOXY OVER AN OLDER COAT. This step can be anything from Diamond Grinding Etching Shot Blasting Scarification and Scabbling.

Source: thermalchem.com

Source: thermalchem.com

Professionals use two methods of preparing the surface acid washing and machine grinding. Extreme heat softens the resin making it easier to remove. Shot blasting is a process in which special equipment is used to help prepare the concrete or cement before epoxy paint can be applied. Correctly prepare the surface before applying any kind of industry-appropriate coating. Do-It-Yourselfers are enthusiastic about acid washing.

Source: brewfloors.com

Source: brewfloors.com

The purpose is to restore the smoothness of the surface and make it even for proper application of epoxy. Leave the plastic in place for at least 24 hours before checking for condensation. If there is water on the plastic you will need to. The first step before applying any epoxy coating is to prep the floor. Professionals use two methods of preparing the surface acid washing and machine grinding.

Source: blackrhinofloors.com

Source: blackrhinofloors.com

If relative humidity is greater than 75 a moisture. This method is the most DIY friendly and doesnt require any heavy machinery as the other methods do for your concrete floor. This step can be anything from Diamond Grinding Etching Shot Blasting Scarification and Scabbling. Acrylic coatings are made up of acrylic resin and a. The first and best epoxy preparation is to allow concrete slabs sufficient time to fully dry in the first place.

Source: toughfloors.com.au

Source: toughfloors.com.au

Substrate preparation is dependent upon the unique structural and environmental conditions found in your facility as well as the specific flooring system you choose to have installedConcrete prep by mechanical means using either a shot-blaster or diamond grinder is now the industry norm. Be sure to catch any areas you might overlook while preparing. Use a wet vacuum and dry the surface to get rid of the water used in rinsing. When applying directly to the substrate the surface should be at least as rough as a 200-300 grit grindsand. Ensure you measure the moisture condition inside the concrete slab before the application begins.

Source: youtube.com

Source: youtube.com

1existing epoxy floor coating is peeling up or showing other signs of delemination 2Do not attempt to apply epoxy over existing concrete sealers. Leave the plastic in place for at least 24 hours before checking for condensation. It is imperative that you clean your floor thoroughly. Your concrete floor wont be able to accept the new coating if the concrete is too damp. The purpose is to restore the smoothness of the surface and make it even for proper application of epoxy.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site helpful, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title how to prepare a concrete floor for epoxy coating by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.