Your How concrete printers work images are available in this site. How concrete printers work are a topic that is being searched for and liked by netizens today. You can Get the How concrete printers work files here. Get all free images.

If you’re looking for how concrete printers work pictures information linked to the how concrete printers work interest, you have come to the right blog. Our website always gives you hints for refferencing the maximum quality video and image content, please kindly surf and locate more enlightening video articles and images that match your interests.

How Concrete Printers Work. A construction 3D printer is a machine that can build houses by depositing a material concrete for example layer by layer. Concrete 3D printing is the shiny new tool in the toolbox of architects and construction companies. And within the limits of the rails the arm will build the house layer by layer by extruding concrete material from the nozzle. The current laser printers you see today were created by Gary Starkweather.

3d Concrete Printer Ebay Concrete 3d Printed Building Printer From pinterest.com

3d Concrete Printer Ebay Concrete 3d Printed Building Printer From pinterest.com

Just instead of a plastic filament concrete 3D printers extrude concrete mixtures specifically manufactured for that project. The rails are arranged to let the robotic arm move. Conventionally mixed concrete generally gains its full strength after 24 days but this is far from a conventional mixture so expect your print to be. There are technological hurdles to overcome however before 3D printing can become a regular feature of modern construction. Its not only about looks though. How does a 3D printer work.

Paste-type material in this case concrete or earth materials is pushed through a nozzle in layers to print buildings in 3D.

Paste-type material in this case concrete or earth materials is pushed through a nozzle in layers to print buildings in 3D. We found that small plastic cups were the best for excavating as they were both soft enough to not damage a print and held enough concrete to be useful. It is fairly similar to how FDM desktop 3D printers work. The finished concrete 3D printer will essentially be a heavily modified and beefed up Shapeoko 2 CNC machine which is an easy to build open source desktop CNC machine. In this design the model pink 40 is printed on a baseplate dark blue 10 that moves in the horizontal XY directions while the print head and nozzle 2 and 4 orange move in the vertical Z direction. He was an employee of Xerox and developed the principles of the laser printer of the Xerox machine which was the flagship model of the company.

Source: pinterest.com

Source: pinterest.com

But Kamp C ingeniously used the stationary COBOD BOD2 concrete printer to print it on-site in one piece. Just instead of a plastic filament concrete 3D printers extrude concrete mixtures specifically manufactured for that project. Concrete 3D printing is the shiny new tool in the toolbox of architects and construction companies. How does 3D printing concrete work. The finished concrete 3D printer will essentially be a heavily modified and beefed up Shapeoko 2 CNC machine which is an easy to build open source desktop CNC machine.

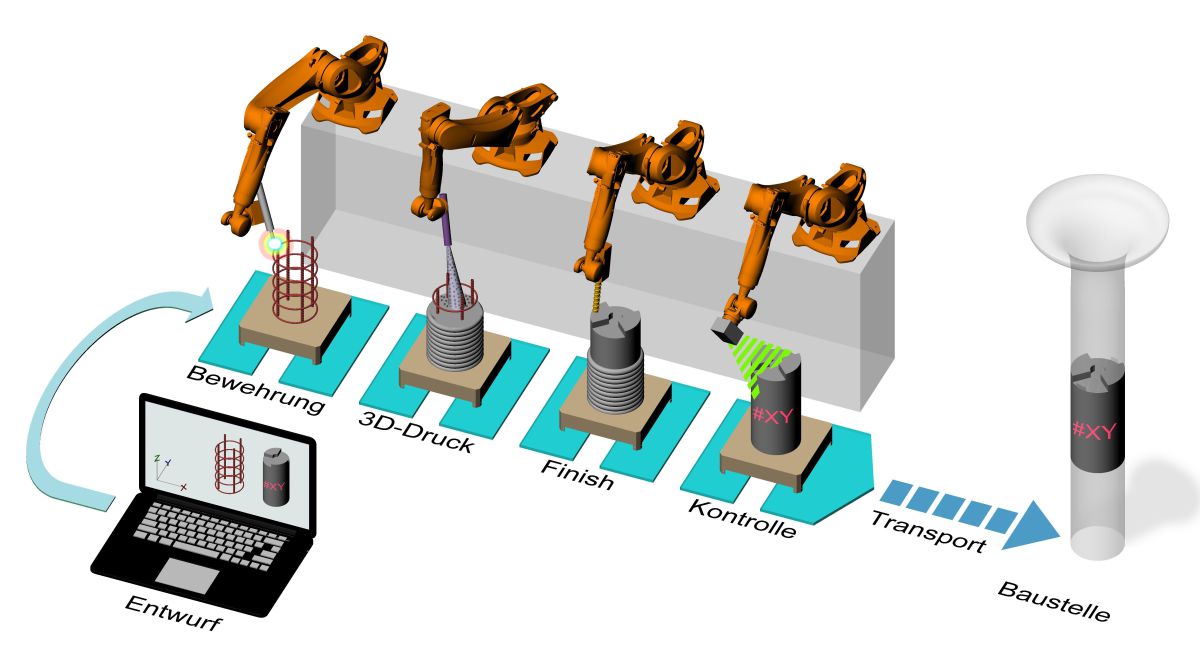

Source: bft-international.com

Source: bft-international.com

How does 3D printing concrete work. Up to 9 cash back 3D Printing Concrete Concrete specifically is one of them. Conventionally mixed concrete generally gains its full strength after 24 days but this is far from a conventional mixture so expect your print to be. Concrete 3D printing aka. Paste-type material in this case concrete or earth materials is pushed through a nozzle in layers to print buildings in 3D.

Source: nl.pinterest.com

Source: nl.pinterest.com

In this design the model pink 40 is printed on a baseplate dark blue 10 that moves in the horizontal XY directions while the print head and nozzle 2 and 4 orange move in the vertical Z direction. In this design the model pink 40 is printed on a baseplate dark blue 10 that moves in the horizontal XY directions while the print head and nozzle 2 and 4 orange move in the vertical Z direction. If you let your print sit even longer it will continue to cure and gain strength. Just instead of a plastic filament concrete 3D printers extrude concrete mixtures specifically manufactured for that project. In a typical concrete 3D printer the material extrusion is done by using a robotic arm with one end attached to the printhead and the other to a crane-like robotic arm system.

Source: pinterest.com

Source: pinterest.com

Up to 9 cash back 3D Printing Concrete Concrete specifically is one of them. But rather than some of. In summary 3D concrete printing is on the rise. Cementitious 3D construction printing 3DCP or 3D concrete printing is a form of additive manufacturing used to fabricate buildings or construction components in completely new shapes not previously possible with traditional concrete formwork. One such is the corrugated or corduroy appearance of 3D-printed concrete.

Source: pinterest.com

Source: pinterest.com

This is a result of the printing process which builds elements by laying down a 12mm-diameter bead of concrete. Heres an introduction explaining how concrete 3D printing works different concrete 3D printing applications and what the benefits and limitations are. How does 3D printing concrete work. Paste-type material in this case concrete or earth materials is pushed through a nozzle in layers to print buildings in 3D. In a typical concrete 3D printer the material extrusion is done by using a robotic arm with one end attached to the printhead and the other to a crane-like robotic arm system.

Source: ar.pinterest.com

Source: ar.pinterest.com

If you let your print sit even longer it will continue to cure and gain strength. Heres an introduction explaining how concrete 3D printing works different concrete 3D printing applications and what the benefits and limitations are. Conventionally mixed concrete generally gains its full strength after 24 days but this is far from a conventional mixture so expect your print to be. Its not only about looks though. How Does 3d Concrete Printing Work.

Source: pinterest.com

Source: pinterest.com

And within the limits of the rails the arm will build the house layer by layer by extruding concrete material from the nozzle. It functions very similarly to a standard FDM printer when it comes to 3D printing concrete. Conventionally mixed concrete generally gains its full strength after 24 days but this is far from a conventional mixture so expect your print to be. There are other smaller subcategories such as Dot Matrix and Solid Ink too. Cementitious 3D construction printing 3DCP or 3D concrete printing is a form of additive manufacturing used to fabricate buildings or construction components in completely new shapes not previously possible with traditional concrete formwork.

Source: pinterest.com

Source: pinterest.com

Construction 40 is a similar 3D printing technology to the one that FFF 3D printers use. In short printers work by converting digital images and text into physical copies. If you let your print sit even longer it will continue to cure and gain strength. A standard concrete 3D printer functions very similarly to a standard FDM printer. While the 3D concrete printing is not as mainstream as 3D printing in the aeronautical or medical industries for.

Source: bft-international.com

Source: bft-international.com

But Kamp C ingeniously used the stationary COBOD BOD2 concrete printer to print it on-site in one piece. The current laser printers you see today were created by Gary Starkweather. We found that small plastic cups were the best for excavating as they were both soft enough to not damage a print and held enough concrete to be useful. Its not only about looks though. 3D printing in concrete doesnt appear just to be a grassroots movement either.

Source: pinterest.com

Source: pinterest.com

COBOD or Construction of Building on Demand developed the BOD2 3D printer which operates on three axes making it possible to print in a circular design on-site and more importantly print multiple floors. But Kamp C ingeniously used the stationary COBOD BOD2 concrete printer to print it on-site in one piece. But rather than some of. They do this using a driver or. Up to 9 cash back 3D Printing Concrete Concrete specifically is one of them.

Source: pinterest.com

Source: pinterest.com

One such is the corrugated or corduroy appearance of 3D-printed concrete. Concrete 3D printers work in the same way as an FDM 3D printer they both print layers to create the finished object. Heres an introduction explaining how concrete 3D printing works different concrete 3D printing applications and what the benefits and limitations are. After its completion the first laser printer was named Dover and was sold by the company for a whopping 300000 per unit. We found that small plastic cups were the best for excavating as they were both soft enough to not damage a print and held enough concrete to be useful.

Source: all3dp.com

Source: all3dp.com

The Basics The way in which printers work is quite simple. They do this using a driver or. In a typical concrete 3D printer the material extrusion is done by using a robotic arm with one end attached to the printhead and the other to a crane-like robotic arm system. A typical concrete 3D printer is designed to additively manufacture parts though material extrusion consisting of a robotic arm with one end attached to the printhead and the other either to a gantry or crane-like robotic. Heres an introduction explaining how concrete 3D printing works different concrete 3D printing applications and what the benefits and limitations are.

Source: pinterest.com

Source: pinterest.com

For the most part a concrete printer is doing nothing more than printing a hollow wall shell that can be filled with rebar and concrete. In this design the model pink 40 is printed on a baseplate dark blue 10 that moves in the horizontal XY directions while the print head and nozzle 2 and 4 orange move in the vertical Z direction. Scott Crump in the 1980s. Just instead of a plastic filament concrete 3D printers extrude concrete mixtures specifically manufactured for that project. COBOD or Construction of Building on Demand developed the BOD2 3D printer which operates on three axes making it possible to print in a circular design on-site and more importantly print multiple floors.

Source: pinterest.com

Source: pinterest.com

It is fairly similar to how FDM desktop 3D printers work. It is fairly similar to how FDM desktop 3D printers work. Conventionally mixed concrete generally gains its full strength after 24 days but this is far from a conventional mixture so expect your print to be. Paste-type material in this case concrete or earth materials is pushed through a nozzle in layers to print buildings in 3D. But Kamp C ingeniously used the stationary COBOD BOD2 concrete printer to print it on-site in one piece.

Source: pinterest.com

Source: pinterest.com

They do this using a driver or. The rails are arranged to let the robotic arm move. But Kamp C ingeniously used the stationary COBOD BOD2 concrete printer to print it on-site in one piece. How does 3D printing concrete work. Up to 9 cash back 3D Printing Concrete Concrete specifically is one of them.

Source: pinterest.com

Source: pinterest.com

And within the limits of the rails the arm will build the house layer by layer by extruding concrete material from the nozzle. In summary 3D concrete printing is on the rise. One such is the corrugated or corduroy appearance of 3D-printed concrete. In short printers work by converting digital images and text into physical copies. Up to 9 cash back 3D Printing Concrete Concrete specifically is one of them.

Source: ar.pinterest.com

Source: ar.pinterest.com

The current laser printers you see today were created by Gary Starkweather. This is a result of the printing process which builds elements by laying down a 12mm-diameter bead of concrete. Scott Crump in the 1980s. For the most part a concrete printer is doing nothing more than printing a hollow wall shell that can be filled with rebar and concrete. We found that small plastic cups were the best for excavating as they were both soft enough to not damage a print and held enough concrete to be useful.

Source: bft-international.com

Source: bft-international.com

3D printing in concrete doesnt appear just to be a grassroots movement either. He was an employee of Xerox and developed the principles of the laser printer of the Xerox machine which was the flagship model of the company. But Kamp C ingeniously used the stationary COBOD BOD2 concrete printer to print it on-site in one piece. Concrete 3D printing is the shiny new tool in the toolbox of architects and construction companies. The finished concrete 3D printer will essentially be a heavily modified and beefed up Shapeoko 2 CNC machine which is an easy to build open source desktop CNC machine.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site good, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title how concrete printers work by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.