Your Dense monolithic concrete walls and floors images are ready in this website. Dense monolithic concrete walls and floors are a topic that is being searched for and liked by netizens today. You can Find and Download the Dense monolithic concrete walls and floors files here. Find and Download all royalty-free vectors.

If you’re searching for dense monolithic concrete walls and floors pictures information connected with to the dense monolithic concrete walls and floors keyword, you have pay a visit to the right blog. Our site always provides you with hints for seeing the maximum quality video and image content, please kindly surf and find more informative video content and graphics that match your interests.

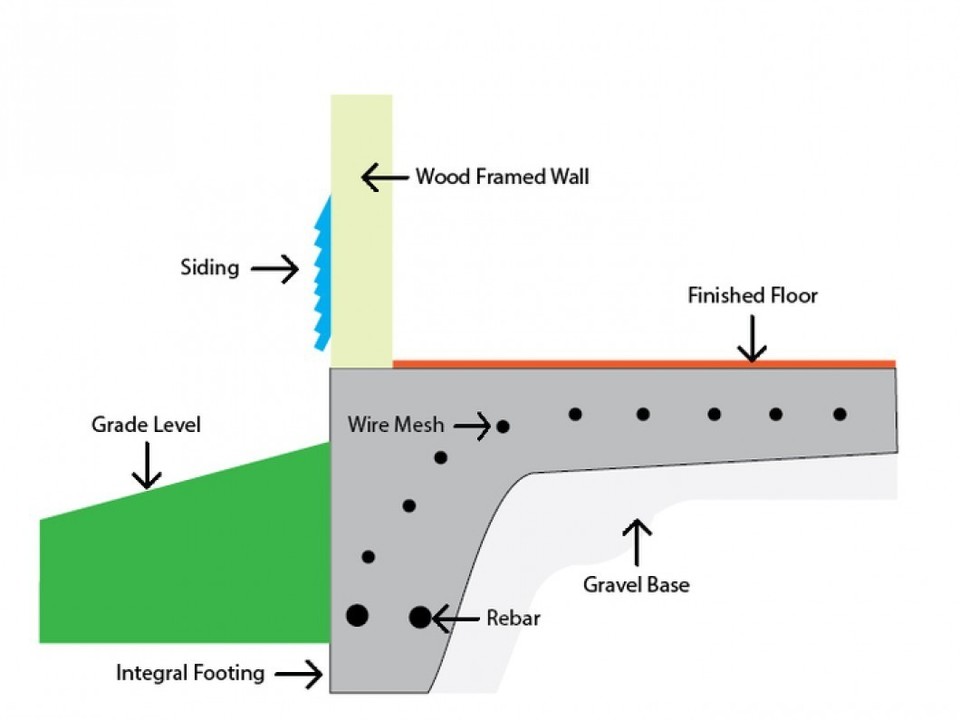

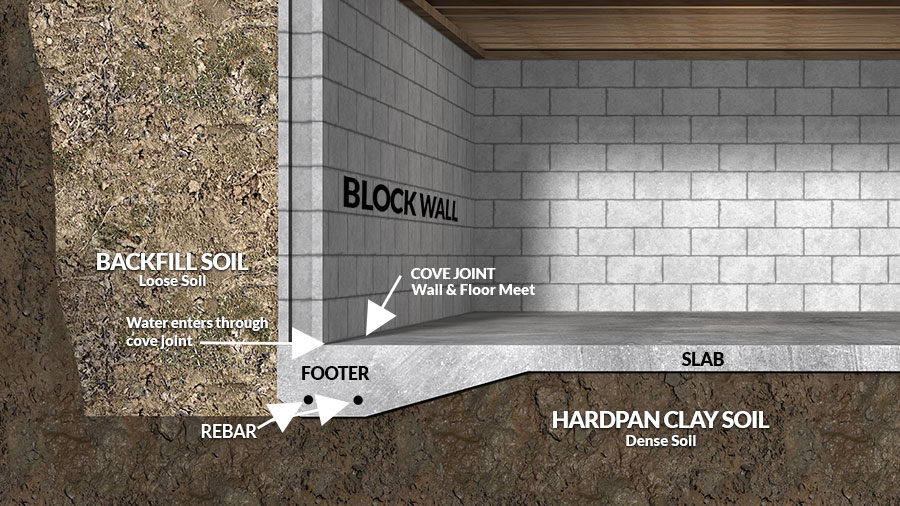

Dense Monolithic Concrete Walls And Floors. But there are a few exceptions to the rule you may use if you need to. In most homes the footing and basement walls made of stone or concrete are inside this clay bowl and sit atop a dense undisturbed soil. Sharp changes in cross section of floors and walls should be avoided. Crosswall construction has the ability to connect walls and floors together avoiding the need for a steel or concrete frame.

Monolithic Slabs House Foundation Concrete Floors Concrete Home From pinterest.com

Monolithic Slabs House Foundation Concrete Floors Concrete Home From pinterest.com

Density and a well-graded gravel of the subbase layer. If all 8 of the block are visible then we know the wall is resting on top of the floor and that you have a monolithic floor. Insulated Stem Wall Rigid insulation full height on the inside of the stem wall. Use of dense monolithic concrete walls and floor. As a result MagnaDense concrete gives full protection but uses less space. They may not want cold joints due to strength reasons or crack lines in the concrete for various reasons.

If theres 5 visible then your floor is three inches thick.

In practice shotcrete often reaches 8000 psi in 28-days. As a result MagnaDense concrete gives full protection but uses less space. Simply so how deep is a monolithic slab. One of the most effective and least invasive methods of waterproofing a basement is with a baseboard system such as Basement Systems DryTrakWith this system weep holes are drilled into the floorwall joint or in the case of a block wall into the walls. Reduced permeability by using admixes eg. Use of dense Monolithic Concrete In this method dense high quality materials good workman ship and attention to design detail and on site construction methods are essential.

Source: pinterest.com

Source: pinterest.com

They may not want cold joints due to strength reasons or crack lines in the concrete for various reasons. Use of dense Monolithic Concrete In this method dense high quality materials good workman ship and attention to design detail and on site construction methods are essential. If all 8 of the block are visible then we know the wall is resting on top of the floor and that you have a monolithic floor. The dome shell is so thin. The provision of a dense impervious concrete structure.

Source: pinterest.com

Source: pinterest.com

Note the deep seat cast into the inside of the top of the stem wall. Insulated Stem Wall Rigid insulation full height on the inside of the stem wall. For a typical dome the design is for 4000 psi concrete after 28-days. As a result MagnaDense concrete gives full protection but uses less space. If your home has poured concrete walls.

Source: pinterest.com

Source: pinterest.com

Monolithic concrete floors are frequently designed as plain concrete slabs. THE MONOLITHIC SLAB CONSTRUCTION PROCESS They average only four inches thick and the footings only reach about 12 inches from the base to the top of the floor. If all 8 of the block are visible then we know the wall is resting on top of the floor and that you have a monolithic floor. July 2014 Volume 8 No. A slab one-piece concrete floor sits on top of the footing.

Source: pinterest.com

Source: pinterest.com

Density from 100 to 1200kgm 3. Note the deep seat cast into the inside of the top of the stem wall. Should be dense free of crack or any differential movement. Monolithic concrete floors are frequently designed as plain concrete slabs. This means youll only have to dig down about.

Source: pinterest.com

Source: pinterest.com

If theres 5 visible then your floor is three inches thick. They should be designed to act monolithically with floors and walls continuously and sharp changes in cross section of the floors and walls should be avoided. Should be dense free of crack or any differential movement. Monolithic concrete floors are frequently designed as plain concrete slabs. Use of dense monolithic concrete walls and floor.

Source: pinterest.com

Source: pinterest.com

Reduced permeability by using admixes eg. Monolithic foamed concrete is made directly on the site. Trust me on this or go back and read BSI-003. Contrary standard concrete typically has a density of up to 24 tm³. Precast Concrete Floor Wall and Frame Construction Process.

Source: pinterest.com

Source: pinterest.com

Masonry and Concrete Walls D-211. Monolithic foamed concrete is made directly on the site. They tend to crack along the thickened perimeter when significant weight loads are used like block exterior walls. Water reducing agent pozzulanic products pore refiner etc. Because of the way a monolithic slab is poured its simple for contractors to reinforce the concrete.

Source: pinterest.com

Source: pinterest.com

Primary elements of precast concrete construction consists of frame walls and floors. DryTrak is designed to solve water leakage in monolithic foundations. They may not want cold joints due to strength reasons or crack lines in the concrete for various reasons. If theres 5 visible then your floor is three inches thick. We supply the mortar to the construction site using concrete pumps.

Source: pinterest.com

Source: pinterest.com

Density from 100 to 1200kgm 3. They may not want cold joints due to strength reasons or crack lines in the concrete for various reasons. The term Monolithic means all in one demolition so in the construction where the Monolithic Slab is used the foundation is made of a single layer of a concrete slide with thick areas under the load-bearing walls and all the edges around the foot support. If all 8 of the block are visible then we know the wall is resting on top of the floor and that you have a monolithic floor. One of the most effective and least invasive methods of waterproofing a basement is with a baseboard system such as Basement Systems DryTrakWith this system weep holes are drilled into the floorwall joint or in the case of a block wall into the walls.

Source: pinterest.com

Source: pinterest.com

Learn more about it. One of the most effective and least invasive methods of waterproofing a basement is with a baseboard system such as Basement Systems DryTrakWith this system weep holes are drilled into the floorwall joint or in the case of a block wall into the walls. Answer 1 of 9. Load bearing walls transmit vertical loads and act as shear walls to prevent lateral movement. Therefore our customers use MagnaDense as a concrete aggregate in the concrete formulation to achieve densities of up to 40 tm³.

Source: pinterest.com

Source: pinterest.com

A slab one-piece concrete floor sits on top of the footing. Crosswall construction has the ability to connect walls and floors together avoiding the need for a steel or concrete frame. Water reducing agent pozzulanic products pore refiner etc. Density and a well-graded gravel of the subbase layer. Sharp changes in cross section of floors and walls should be avoided.

Source: pinterest.com

Source: pinterest.com

Density from 100 to 1200kgm 3. Contrary standard concrete typically has a density of up to 24 tm³. They should be designed to act monolithically with floors and walls continuously and sharp changes in cross section of the floors and walls should be avoided. Load bearing walls transmit vertical loads and act as shear walls to prevent lateral movement. Design of Monolithic Concrete Ground Floors-8-14pdf.

Source: researchgate.net

Source: researchgate.net

Crosswall construction has the ability to connect walls and floors together avoiding the need for a steel or concrete frame. DryTrak is designed to solve water leakage in monolithic foundations. THE MONOLITHIC SLAB CONSTRUCTION PROCESS They average only four inches thick and the footings only reach about 12 inches from the base to the top of the floor. Simply so how deep is a monolithic slab. A slab one-piece concrete floor sits on top of the footing.

Source: pinterest.com

Source: pinterest.com

Simply so how deep is a monolithic slab. Where there is a necessity for insulation or as where the basement is desirable for living quarters then concrete is cast with light weight aggregate that may be prepared by calcining or sintering blast furnace slab clay or shale that will fulfill the requirements of ASTM standard c330. As a result MagnaDense concrete gives full protection but uses less space. If the tool enters horizontally we know that the wall is sitting on top of the floor and you. Lateral support can also be achieved by transmitting loads via the floor slab back to lift shafts stair cores or other.

Source: a-concrete.com

Source: a-concrete.com

We supply the mortar to the construction site using concrete pumps. THE MONOLITHIC SLAB CONSTRUCTION PROCESS They average only four inches thick and the footings only reach about 12 inches from the base to the top of the floor. Lateral support can also be achieved by transmitting loads via the floor slab back to lift shafts stair cores or other. Should be dense free of crack or any differential movement. July 2014 Volume 8 No.

Source: pinterest.com

Source: pinterest.com

This seat will receive the perimeter edge insulation and the perimeter slab. In practice shotcrete often reaches 8000 psi in 28-days. Monolithic foamed concrete is made directly on the site. Density and a well-graded gravel of the subbase layer. Sharp changes in cross section of floors and walls should be avoided.

Source: pinterest.com

Source: pinterest.com

Learn more about it. July 2014 Volume 8 No. Primary elements of precast concrete construction consists of frame walls and floors. Because of the way a monolithic slab is poured its simple for contractors to reinforce the concrete. Answer 1 of 9.

Source: americandry.com

Source: americandry.com

The term Monolithic means all in one demolition so in the construction where the Monolithic Slab is used the foundation is made of a single layer of a concrete slide with thick areas under the load-bearing walls and all the edges around the foot support. Aerated concrete lowers concrete density and compressive strength. If the tool enters horizontally we know that the wall is sitting on top of the floor and you. The provision of a dense impervious concrete structure. Answer 1 of 9.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site adventageous, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title dense monolithic concrete walls and floors by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.