Your Curing time for 4 concrete slab images are available in this site. Curing time for 4 concrete slab are a topic that is being searched for and liked by netizens today. You can Download the Curing time for 4 concrete slab files here. Download all free images.

If you’re looking for curing time for 4 concrete slab images information linked to the curing time for 4 concrete slab keyword, you have come to the ideal blog. Our site always provides you with hints for seeking the maximum quality video and image content, please kindly hunt and locate more informative video content and images that match your interests.

Curing Time For 4 Concrete Slab. Is a way to determine if the concrete has gained enough strength to be on its own and it relies on the combination of time and temperature. Mudjacking also known as slab jacking or. Watch the animation to learn how Bio-San C500s robust dual technology system eliminates the problem. Answer 1 of 4.

Curing Of Concrete Curing Time And Duration Curing Methods Engineering Discoveries From civilengdis.com

Curing Of Concrete Curing Time And Duration Curing Methods Engineering Discoveries From civilengdis.com

If there is a risk of freezing cover the slab with an insulator such as insulating blankets or a 4-inch-thick layer of straw that is weighted down to prevent it from blowing away. During the curing process there is excess moisture still evaporating from the concrete that can ruin the floor if you install it too. Curing of Concrete Remove the Formwork. DO cover new concrete. Curing of the concrete slab by water is near about seven days. Further the article written as 6 factors affecting curing time of concrete could provide more information to decide the period of curing.

Multiply the length 10 ft by the width 10 ft by the depth 35 ft or 4 in and divide it by 27 the number of cubic feet in a.

If you have clay or loam soil you should remove enough to allow a 6- to 8-in. If we use spray curing then we must spray two times a day. Curing of Concrete Remove the Formwork. The R value measures how well a building material eg. Place a curing compound over the surface or provide appropriate moist curing. Learn more about the maturity method PDF.

Source: thespruce.com

Source: thespruce.com

To ensure a solid base for your concrete pad a compacted gravel base which is 4 6s thick needs to be put down. For heavier loads or in cold areas with deep frost you may want it 8 12s thick. Steel-reinforced slabs typically between 100 and 500 mm thick are most often used to construct floors and ceilings while thinner mud slabs may be used for exterior paving see belowIn many domestic and industrial buildings a thick. If we did not cure the concrete the following main issues will rise. Curing of concrete is one of the most important factors in concrete construction as it is related to properties such as characteristic strength permeability durability etcFurther it is required to do the curing at the right time and a sufficient period of curing is very important to achieve the exact properties of concrete.

Source: pinterest.com

Source: pinterest.com

To determine how much insulating value you need to keep the concrete at 50F check out the tables in Chapter 7 of ACI. ContentsConcrete Floor Slab Construction Process1. Foundations basements garage floors load-bearing concrete. Well use a 10 x 10 ft. Mudjacking also known as slab jacking or.

Source: pinterest.com

Source: pinterest.com

Remember all values should be computed in m. Multiply the length 10 ft by the width 10 ft by the depth 35 ft or 4 in and divide it by 27 the number of cubic feet in a. The foundations- clearly a slab poured onto solid rock just to create a level platfo. The quality of a concrete floor or slab is highly dependent on achieving a hard and durable surface that is flat relatively free of cracks and at the proper grade and elevation. Assemble and Erect Formwork for Slab2.

Source: pinterest.com

Source: pinterest.com

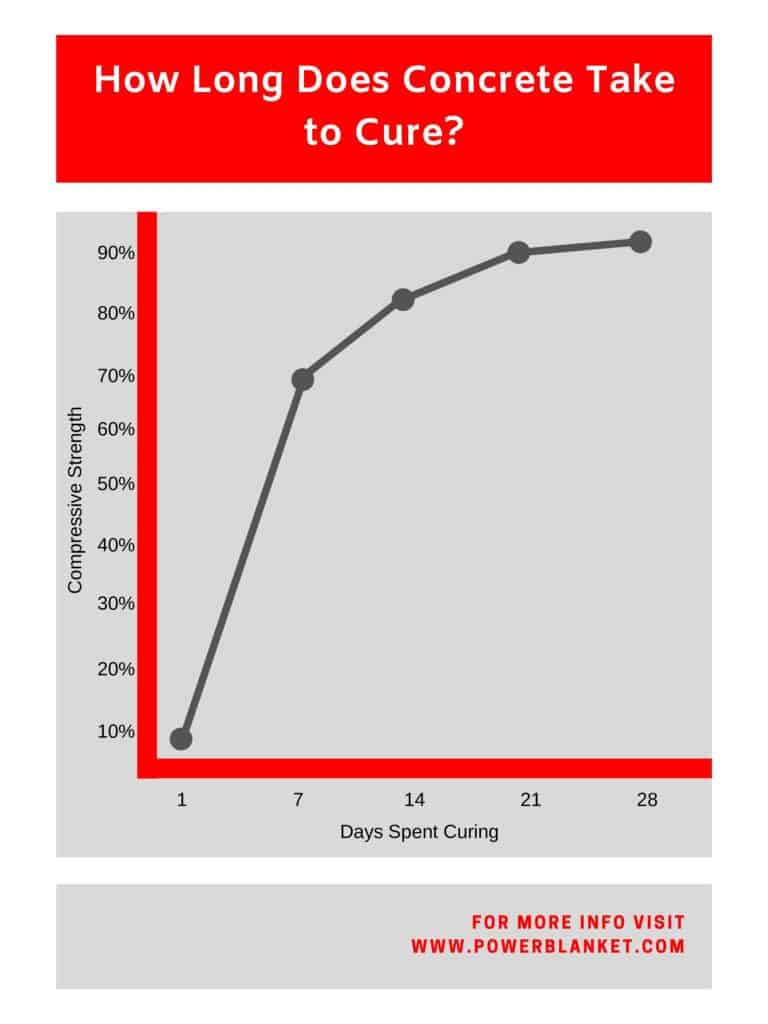

69973 60 50 40 30 20 10 0 0 7 28 90 365 8 6 4 2 0 Age at test days Moist-cured entire time In air after 28 days moist curing In air after 7. A concrete slab is a common structural element of modern buildings consisting of a flat horizontal surface made of cast concrete. Steel-reinforced slabs typically between 100 and 500 mm thick are most often used to construct floors and ceilings while thinner mud slabs may be used for exterior paving see belowIn many domestic and industrial buildings a thick. It is however wise to make the perimeter of the slab an inch or two thicker. Further the article written as 6 factors affecting curing time of concrete could provide more information to decide the period of curing.

Source: in.pinterest.com

Source: in.pinterest.com

Well use a 10 x 10 ft. For heavier loads or in cold areas with deep frost you may want it 8 12s thick. Remember all values should be computed in m. A concrete slab resists the conductive flow of heat. The mix of concrete used- ratio of cement to sand to gravel size of gravel and any additives Reinforcement- re-enforced concrete is stronger.

Source: pinterest.com

Source: pinterest.com

Foundations basements garage floors load-bearing concrete. To determine how much insulating value you need to keep the concrete at 50F check out the tables in Chapter 7 of ACI. Answer 1 of 4. ContentsConcrete Floor Slab Construction Process1. Heres a brief rundown of what you need to know about concrete and concrete prices.

Source: everreadymix.co.uk

Source: everreadymix.co.uk

Curing of Concrete Remove the Formwork. Heres a brief rundown of what you need to know about concrete and concrete prices. There are times where thicker slabs will make more sense but most of the time 4 inches is the perfect thickness for a concrete slab. Bone Dry has been the solution to CaCl and RH troubles in new and existing concrete. After 24 hours of concrete poured the formwork.

Source: homeefficiencyguide.com

Source: homeefficiencyguide.com

After the concrete is being poured it needs to vibration for compaction. For a concrete patio the ideal slab thickness is at least four inches. 30 minutes 1 hour. Is a way to determine if the concrete has gained enough strength to be on its own and it relies on the combination of time and temperature. For a given slab thickness strength depends on.

Source: civilengdis.com

Source: civilengdis.com

Place a curing compound over the surface or provide appropriate moist curing. Multiply the length 10 ft by the width 10 ft by the depth 35 ft or 4 in and divide it by 27 the number of cubic feet in a. During the curing process there is excess moisture still evaporating from the concrete that can ruin the floor if you install it too. For instance is this slab submitted to direct sunlight dry environment and wind incidence. It takes 6 to 8 weeks for concrete to cure depending on climate and the concrete mixture.

Source: ar.pinterest.com

Source: ar.pinterest.com

Place a curing compound over the surface or provide appropriate moist curing. Place a curing compound over the surface or provide appropriate moist curing. Calculate the volume you need in cubic yards. Therefore curing shall not be avoided. Foundations basements garage floors load-bearing concrete.

Source: buildmagazine.org.nz

Source: buildmagazine.org.nz

Your concrete slab will last longer with less cracking and movement if its built on solid well-drained soil. How Much to Pour a Concrete Slab. Steel-reinforced slabs typically between 100 and 500 mm thick are most often used to construct floors and ceilings while thinner mud slabs may be used for exterior paving see belowIn many domestic and industrial buildings a thick. Further the article written as 6 factors affecting curing time of concrete could provide more information to decide the period of curing. The R value for an uninsulated concrete slab is approximately 01 per 150mm.

Source: powerblanket.com

Source: powerblanket.com

Slab as an example. It takes 6 to 8 weeks for concrete to cure depending on climate and the concrete mixture. Multiply the length 10 ft by the width 10 ft by the depth 35 ft or 4 in and divide it by 27 the number of cubic feet in a. This is good to use ready mix concrete but all the time we cant use ready mix concrete. ContentsConcrete Floor Slab Construction Process1.

Source: gharpedia.com

Source: gharpedia.com

Watch the animation to learn how Bio-San C500s robust dual technology system eliminates the problem. 1 minute Curing of cement concrete is defined as the process of maintaining the moisture and temperature conditions of concrete for hydration reaction to normally so that concrete develops hardened properties over time. In this case the chosen curing procedure is extremely important. 24 48 hours. Remember all values should be computed in m.

Source: pinterest.com

Source: pinterest.com

Leave the insulator in place. Is a way to determine if the concrete has gained enough strength to be on its own and it relies on the combination of time and temperature. During the curing process there is excess moisture still evaporating from the concrete that can ruin the floor if you install it too. Concrete floor slab construction process includes erection of formwork placement of reinforcement pouring compacting and finishing concrete and lastly removal of formwork and curing of concrete slab. The recommended curing time on any concrete element will depend on internal and external factors such as mix proportions size and shape of the slab ambient conditions specified strength etc.

Source: pinterest.com

Source: pinterest.com

30 minutes 1 hour. If representing pavements of a slab on grade bank the sides and ends with earth or sand that must be kept damp leaving the top surface exposed. Curing of the concrete slab by water is near about seven days. Watch the animation to learn how Bio-San C500s robust dual technology system eliminates the problem. For a given slab thickness strength depends on.

Source: pinterest.com

Source: pinterest.com

ContentsConcrete Floor Slab Construction Process1. Well use a 10 x 10 ft. After 24 hours of concrete poured the formwork. Steel-reinforced slabs typically between 100 and 500 mm thick are most often used to construct floors and ceilings while thinner mud slabs may be used for exterior paving see belowIn many domestic and industrial buildings a thick. Slabs driveways patios sidewalks steps decks.

Source: pinterest.com

Source: pinterest.com

When you dont have time to revisit your concrete with a hose as many times as necessary for true moist curing another option is to use a cover that can trap and slow the. How Much to Pour a Concrete Slab. When you dont have time to revisit your concrete with a hose as many times as necessary for true moist curing another option is to use a cover that can trap and slow the. The Volume of concrete Length x Breadth x Depth 6x5x01545m 3 Hence 45m 3 of concrete is required to build an above slab. Concrete floor slab construction process includes erection of formwork placement of reinforcement pouring compacting and finishing concrete and lastly removal of formwork and curing of concrete slab.

If we did not cure the concrete the following main issues will rise. After the concrete is being poured it needs to vibration for compaction. For heavier loads or in cold areas with deep frost you may want it 8 12s thick. 1 minute Curing of cement concrete is defined as the process of maintaining the moisture and temperature conditions of concrete for hydration reaction to normally so that concrete develops hardened properties over time. 30 minutes 1 hour.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site serviceableness, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title curing time for 4 concrete slab by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.