Your Cracks in elevated concrete slabs images are ready. Cracks in elevated concrete slabs are a topic that is being searched for and liked by netizens now. You can Find and Download the Cracks in elevated concrete slabs files here. Download all royalty-free photos and vectors.

If you’re searching for cracks in elevated concrete slabs pictures information related to the cracks in elevated concrete slabs topic, you have come to the right site. Our website always provides you with suggestions for downloading the maximum quality video and image content, please kindly search and find more informative video content and graphics that match your interests.

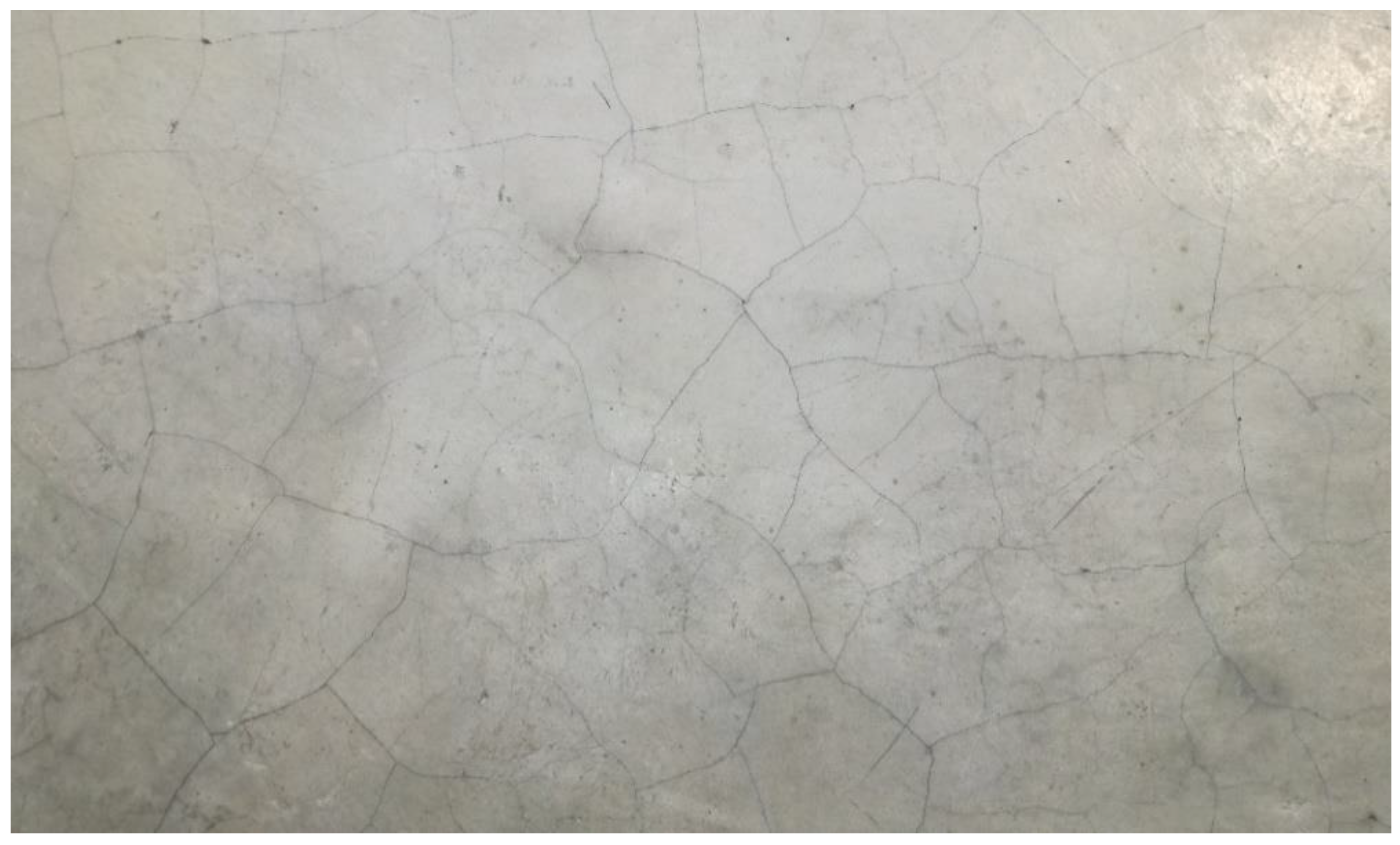

Cracks In Elevated Concrete Slabs. Usually concrete slabs undergo high evaporation due to their large surface area. In most cases these are shrinkage cracks which formed when the concrete cured. Actually cracking in concrete fill is most commonly related to restraint against shrinkage and to the location of the supporting steel members. Hairline Cracks in Concrete Slab.

Pin On Tgg Diy Garden Ideas Projects From pinterest.com

Pin On Tgg Diy Garden Ideas Projects From pinterest.com

Some of the most significant causes are discussed in detail. Due in part to curvature of the section induced by. In the case of concrete fill on metal decks cracking is often erroneously attributed to excessive dead and live loads design or construction errors or even earthquake loads. Actually cracking in concrete fill is most commonly related to restraint against shrinkage and to the location of the supporting steel members. Cracking oc-curs when tensile stresses exceed the tensile strength of concrete. These cracks rarely occur in slabs-on-grade but will always occur on elevated slabs if not reinforced with rebar or welded wire fabric.

These pours require a bit more skill than your everyday residential concrete driveway and will need to be carried out by a professional contractor.

In general if the crack is stable and not leaking water it does not indicate a structural problem. Multiple factors are involved in pouring elevated. If a tree is located too close to a concrete slab the growing roots can lift and crack the concrete Alkali-Silica Reaction Cracks The chemical reaction between the alkali hydroxide in the concrete and reactive aggregates produces an expansive gel causing map cracking or directional cracking prestressed members in the structure. This amount of steel controls cracking if its placed near the top of the slab with 3 4 to 1 inch of cover. There are good reasons for building or buying a house on a slab such as cost savings and less risk of damage in certain instances. These cracks are considered structural failure cracks and are wider and predictable not random.

Source: pinterest.com

Source: pinterest.com

Although epoxy injection is often used significant cracks caused by settlement or other changes need to be stabilized with a structural concrete crack repair process otherwise they can. For a narrow crack like this you can use a self. The deck spans 10ft continuous spans and bear on cold formed metal walls. These pours require a bit more skill than your everyday residential concrete driveway and will need to be carried out by a professional contractor. Multiple factors are involved in pouring elevated.

Source: concretenetwork.com

Source: concretenetwork.com

I think the best solution to eliminate or at least keep the cracks tight is to limit beam deflections to L480 to L600 if you can. Keep an eye on the crack to make sure it is not growing which would indicate a more serious problem. Concrete can crack due to a number of causes. Although epoxy injection is often used significant cracks caused by settlement or other changes need to be stabilized with a structural concrete crack repair process otherwise they can. This behavior has been observed in slabs in which design andor construction errors have been identified and in properly designed and constructed slabs.

Source: mdpi.com

Source: mdpi.com

Oftentimes cracks in slabs are repaired by epoxy injection or filling the surface of the crack and while that may appear to fix the problem these repairs usually fail and result in call-backs or further problems. Cracks also occur due to excessive flexural stresses brought on by bending when spanning distances. Im not sure why its cracking so much but with the reinforcing in and we are 10 days old it seems like. Tight cracks are common in concrete slabs. A PSI of 2000 3000 4000 or 5000 refers to the pounds per square inch necessary to crush a concrete slab.

Source: mdpi.com

Source: mdpi.com

Tight cracks are common in concrete slabs. Concrete cracks and selecting the best repair method is important. This amount of steel controls cracking if its placed near the top of the slab with 3 4 to 1 inch of cover. For a narrow crack like this you can use a self. Hairline Cracks in Concrete Slab.

Source: giatecscientific.com

Source: giatecscientific.com

In general if the crack is stable and not leaking water it does not indicate a structural problem. The deck spans 10ft continuous spans and bear on cold formed metal walls. In most cases this is due to an uneven seat for the slab itself such as poorly compacted subsoil invasive pressure from tree roots previous concrete slabs that have not been removed or repeated expansions and contractions in the rebar. Pouring concrete when conditions are too hot above 77 degF your case means that some of the water hydrating the concrete evaporates rather than joining in the chemical reaction increasing the chances of shrinkage cracks as well as making for a. The excessive weight placed on top of a concrete slab can cause cracking.

Source: homeguides.sfgate.com

Source: homeguides.sfgate.com

When the evaporation rate is higher than the bleeding rate the top of the slab surface shrinks due to drying and cracks at the end. Concrete can crack due to a number of causes. The disadvantages include that heating and cooling units may have to be installed on the ground floor which takes up living space. Hairline Cracks in Concrete Slab. These pours require a bit more skill than your everyday residential concrete driveway and will need to be carried out by a professional contractor.

Source: pinterest.com

Source: pinterest.com

For a narrow crack like this you can use a self. A PSI of 2000 3000 4000 or 5000 refers to the pounds per square inch necessary to crush a concrete slab. The slab is cracking like crazy every 12 or 36 parallel with the span. Elevated concrete slabs also known as suspended concrete slabs are most commonly found in commercial offices parking garages and other multistory heavy-use buildings. Therefore to control concrete cracking the tensile.

Source: pinterest.com

Source: pinterest.com

I think the best solution to eliminate or at least keep the cracks tight is to limit beam deflections to L480 to L600 if you can. However its virtually impossible for contractors to keep the welded wire fabric near the top of the slab be-cause it gets pushed down by work-ers feet pump lines and the weight of the concrete. In most cases these are shrinkage cracks which formed when the concrete cured. Some of the most significant causes are discussed in detail. An tell your Clients that this is the beauty of concrete it cracks where it wants to.

Source: pinterest.com

Source: pinterest.com

In most cases this is due to an uneven seat for the slab itself such as poorly compacted subsoil invasive pressure from tree roots previous concrete slabs that have not been removed or repeated expansions and contractions in the rebar. If a tree is located too close to a concrete slab the growing roots can lift and crack the concrete Alkali-Silica Reaction Cracks The chemical reaction between the alkali hydroxide in the concrete and reactive aggregates produces an expansive gel causing map cracking or directional cracking prestressed members in the structure. This amount of steel controls cracking if its placed near the top of the slab with 3 4 to 1 inch of cover. The elevated levels are supported by 2 composite steel deck with 2 concrete with 6x6 W14xW14 1 below slab. To be successful you must choose a procedure that addresses the cause of the fracture and present condition of the slab.

Source: ardexbuildingproducts.ie

Source: ardexbuildingproducts.ie

Although epoxy injection is often used significant cracks caused by settlement or other changes need to be stabilized with a structural concrete crack repair process otherwise they can. Some of the most significant causes are discussed in detail. Actually cracking in concrete fill is most commonly related to restraint against shrinkage and to the location of the supporting steel members. The excessive weight placed on top of a concrete slab can cause cracking. The elevated levels are supported by 2 composite steel deck with 2 concrete with 6x6 W14xW14 1 below slab.

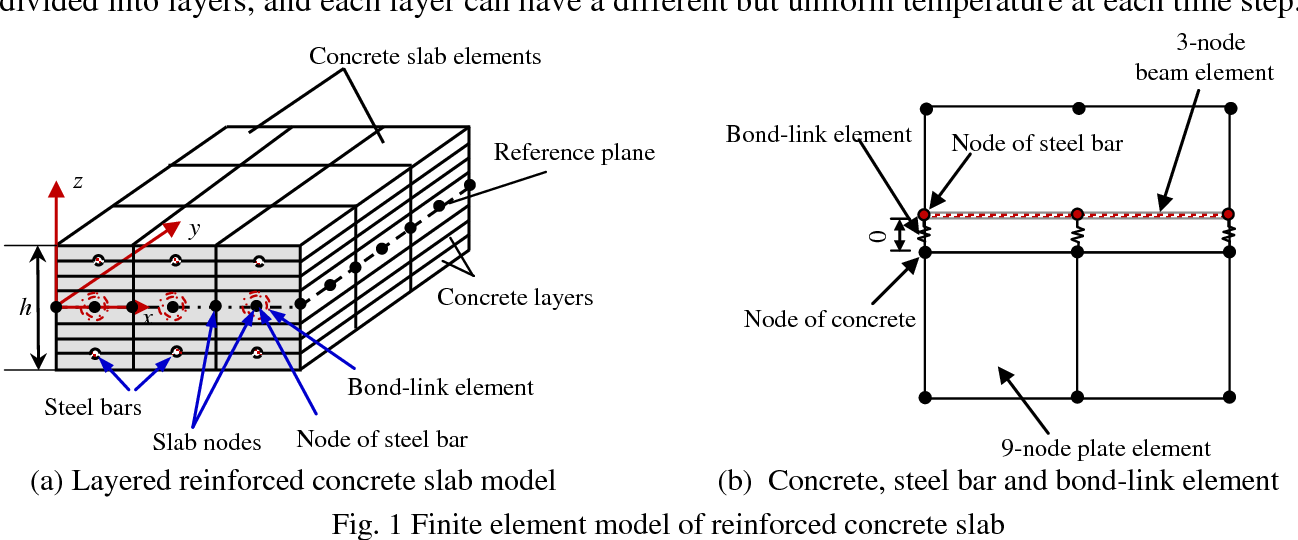

Source: researchgate.net

Source: researchgate.net

Plastic shrinkage cracks in concrete slabs These cracks occur due to the water loss from the concrete. To be successful you must choose a procedure that addresses the cause of the fracture and present condition of the slab. This amount of steel controls cracking if its placed near the top of the slab with 3 4 to 1 inch of cover. Hairline Cracks in Concrete Slab. A PSI of 2000 3000 4000 or 5000 refers to the pounds per square inch necessary to crush a concrete slab.

Source: semanticscholar.org

Source: semanticscholar.org

Keep an eye on the crack to make sure it is not growing which would indicate a more serious problem. If a tree is located too close to a concrete slab the growing roots can lift and crack the concrete Alkali-Silica Reaction Cracks The chemical reaction between the alkali hydroxide in the concrete and reactive aggregates produces an expansive gel causing map cracking or directional cracking prestressed members in the structure. These cracks rarely occur in slabs-on-grade but will always occur on elevated slabs if not reinforced with rebar or welded wire fabric. Solutions with carbon fiber however provide a. The slab is cracking like crazy every 12 or 36 parallel with the span.

Source: researchgate.net

Source: researchgate.net

The excessive weight placed on top of a concrete slab can cause cracking. Offset cracks cause a difference of height in the concrete on either side of the crack. In most cases this is due to an uneven seat for the slab itself such as poorly compacted subsoil invasive pressure from tree roots previous concrete slabs that have not been removed or repeated expansions and contractions in the rebar. There are good reasons for building or buying a house on a slab such as cost savings and less risk of damage in certain instances. Actually cracking in concrete fill is most commonly related to restraint against shrinkage and to the location of the supporting steel members.

Source: concreteconstruction.net

Source: concreteconstruction.net

These pours require a bit more skill than your everyday residential concrete driveway and will need to be carried out by a professional contractor. Excessive weight on the slab after. For a narrow crack like this you can use a self. The slab is cracking like crazy every 12 or 36 parallel with the span. Solutions with carbon fiber however provide a.

Source: familyhandyman.com

Source: familyhandyman.com

In general if the crack is stable and not leaking water it does not indicate a structural problem. This behavior has been observed in slabs in which design andor construction errors have been identified and in properly designed and constructed slabs. In most cases these are shrinkage cracks which formed when the concrete cured. There are good reasons for building or buying a house on a slab such as cost savings and less risk of damage in certain instances. I think the best solution to eliminate or at least keep the cracks tight is to limit beam deflections to L480 to L600 if you can.

Source: mdpi.com

Source: mdpi.com

To be successful you must choose a procedure that addresses the cause of the fracture and present condition of the slab. Hairline cracks in a concrete slab are rarely a cause for concernThey can be controlled but not eliminated. Therefore to control concrete cracking the tensile. The excessive weight placed on top of a concrete slab can cause cracking. Im not sure why its cracking so much but with the reinforcing in and we are 10 days old it seems like.

Source: pinterest.com

Source: pinterest.com

The slab crack at almost every joist location most were hair line but some started to unravel under pallet jack wheel traffic. Plastic shrinkage cracks in concrete slabs These cracks occur due to the water loss from the concrete. Hairline cracks in a concrete slab are rarely a cause for concernThey can be controlled but not eliminated. To be successful you must choose a procedure that addresses the cause of the fracture and present condition of the slab. In the case of concrete fill on metal decks cracking is often erroneously attributed to excessive dead and live loads design or construction errors or even earthquake loads.

Source: waterstopsolutions.com.au

Source: waterstopsolutions.com.au

These cracks are considered structural failure cracks and are wider and predictable not random. For a narrow crack like this you can use a self. Therefore to control concrete cracking the tensile. Hairline cracks in a concrete slab are rarely a cause for concernThey can be controlled but not eliminated. Hairline Cracks in Concrete Slab.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site helpful, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title cracks in elevated concrete slabs by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.