Your Control joints in concrete slabs nz images are available. Control joints in concrete slabs nz are a topic that is being searched for and liked by netizens today. You can Download the Control joints in concrete slabs nz files here. Get all royalty-free photos.

If you’re searching for control joints in concrete slabs nz pictures information connected with to the control joints in concrete slabs nz topic, you have visit the ideal blog. Our site frequently provides you with hints for seeing the maximum quality video and image content, please kindly search and locate more informative video content and graphics that fit your interests.

Control Joints In Concrete Slabs Nz. I plan to use fiber concrete without rebar or mesh and to pour the driveway in slabs. Gain access to expert consultants when required for geotechnical considerations design loads minimum slab thickness etc. The overall depth is 305mm. Contraction joints control the random drying shrinkage cracking of concrete by inducing the slab to crack at the contraction joints.

Concrete Slabs And Control Joints Branz Build From buildmagazine.org.nz

Concrete Slabs And Control Joints Branz Build From buildmagazine.org.nz

The system incorporates a two-part. Isolation joints also sometimes functioning as expansion joints Construction joints which can also function as contraction joints Contraction joints also sometimes called control joints. A fresh concrete mixture is a fluid plastic mass that can be molded into virtually any shape but as the material hardens there is a reduction in volume or shrinkage. Oxford Dictionaries 2 Jamb A vertical side member of a door frame door lining. Decisions relating to these matters should not be made on site they should be discussed with the designer beforehand. Provision of producer statements for.

Our concrete fibre slabs have been around longer than our competitors have been in business.

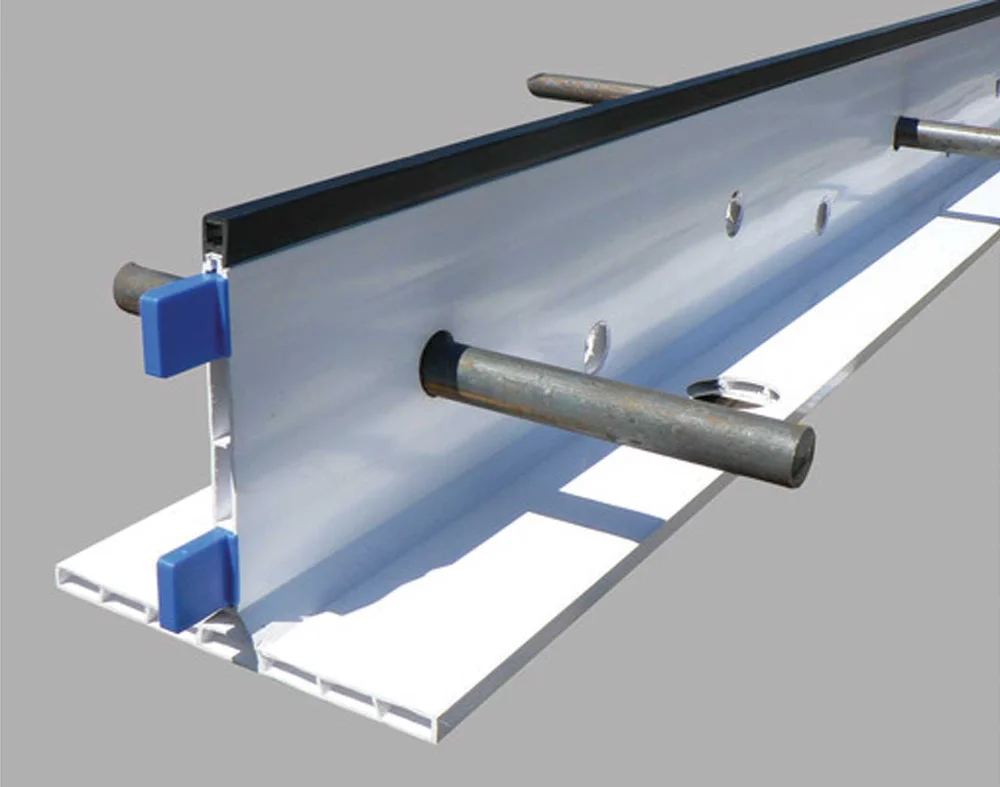

Control joints that are cut into the slab should be formed within 2448 hours after pouring depending on the ambient temperature. Of concrete brickwork masonry or plaster due to the evaporation and crystallisation of the alkaline salts which may be contained in the building materials. In simple terms its a lightweight cast in-place permanent screed rail thats strong enough to handle all types of conventional mechanical screeds. Provision of producer statements for. Expansioncontrol joints are placed in concrete slabs to control random cracking whilst accommodating movement. Our concrete fibre slabs have been around longer than our competitors have been in business.

Source: concretenz.org.nz

Source: concretenz.org.nz

Recommended maximum joint spacing is. Control joints that are cut into the slab should be formed within 2448 hours after pouring depending on the ambient temperature. Do I need to have control joints in the slabs and if so how far apart in a 15-foot-wide driveway. Under NZS 3604 shrinkage control joints if. The Canzac Cover Plate Joint System is designed to accommodate joint openings from 35mm up to 85mm.

Source: concretenz.org.nz

Source: concretenz.org.nz

One of the most effective joints in controlling shrinkage is the keyed joint however this type of joint is very susceptible to damage of the concrete slab edge over the female section of the key and it has questionable load transfer characteristics once it opens up. In simple terms its a lightweight cast in-place permanent screed rail thats strong enough to handle all types of conventional mechanical screeds. Decisions relating to these matters should not be made on site they should be discussed with the designer beforehand. Expansioncontrol joints are placed in concrete slabs to control random cracking whilst accommodating movement. Gain access to expert consultants when required for geotechnical considerations design loads minimum slab thickness etc.

Source: bitjustmipo1984.mystrikingly.com

Source: bitjustmipo1984.mystrikingly.com

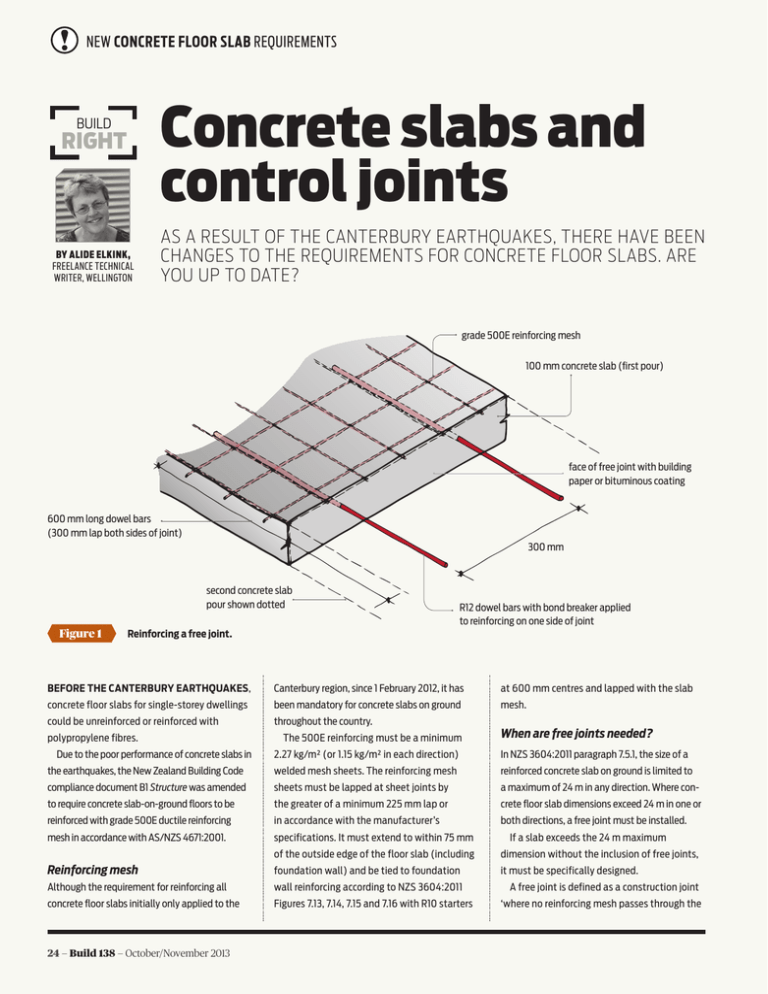

The system incorporates a two-part. The choice of mesh type and location of control joints should be detailed on the drawings and contract documents. For slabs designed to NZS 36042011 the spacing of saw-cut joints shrinkage movement joints and location of the reinforcing mesh are all important in avoiding shrinkage cracking. Cutting control joints into the concrete with a diamond saw adds more time on top this. A shrinkage control joint is defined in NZS 3804 as a line along which the horizontal strength of a slab is deliberately reduced so that any shrinkage in the slab will result in a crack forming along that line.

Source: buildmagazine.org.nz

Source: buildmagazine.org.nz

I really dont want any but dont want cracking either. Contractioncontrol joints are placed in concrete slabs to control random cracking. The Canzac Cover Plate Joint System is designed to accommodate joint openings from 35mm up to 85mm. Section 75 of NZS 3604 sets out the maximum spacing for shrinkage control joints in slabs with different levels of reinforcing. Expansion joints or isolation joints are used between two different concrete pours or where concrete meets with another material or even a structure.

Source: buildmagazine.org.nz

Source: buildmagazine.org.nz

In order to ensure that shrinkage cracking occurs at a contraction joint a plane of. Methods adopted to increase the early shrinkage should not however compromise the integrity or durability of the concrete. Steel Fibres strengthen concrete by resisting tensile cracking and have a higher flexural strength than that of un-reinforced concrete and concrete reinforced with wire mesh. Using dowels for slabs below 150mm is not recommended. With high early shrinkage the crack inducer grid gets a chance to kick in before the concrete attains significant tensile strength to resist cracking.

Source: lesasystems.co.nz

Source: lesasystems.co.nz

Limited draw on the groove is needed. Expansioncontrol joints are placed in concrete slabs to control random cracking whilst accommodating movement. Cracking is most likely to occur at major changes of plan so NZS 36042011 paragraph 75864 requires that shrinkage control joints. Typically it consists of an 85mm thick slab supported by a grid of ribs normally 100mm wide at 1200mm x 1200mm centres. K-Form is made from uPVC.

Source: 4s.co.nz

Source: 4s.co.nz

Both sides of the concrete slab and the vertical faces of the joint are not in bonded contact with each other. The Canzac Cover Plate Joint System is designed to accommodate joint openings from 35mm up to 85mm. Section 75 of NZS 3604 sets out the maximum spacing for shrinkage control joints in slabs with different levels of reinforcing. Of concrete brickwork masonry or plaster due to the evaporation and crystallisation of the alkaline salts which may be contained in the building materials. Contraction joints control the random drying shrinkage cracking of concrete by inducing the slab to crack at the contraction joints.

Source: concretenz.org.nz

Source: concretenz.org.nz

Edge beams and ribs under load bearing walls are 300mm. One of the most effective joints in controlling shrinkage is the keyed joint however this type of joint is very susceptible to damage of the concrete slab edge over the female section of the key and it has questionable load transfer characteristics once it opens up. For slabs designed to NZS 36042011 the spacing of saw-cut joints shrinkage movement joints and location of the reinforcing mesh are all important in avoiding shrinkage cracking. In simple terms its a lightweight cast in-place permanent screed rail thats strong enough to handle all types of conventional mechanical screeds. The Australian code AS 2870 can be used and this code requires movement joints at 18 metres centres maximum.

Source: buildmagazine.org.nz

Source: buildmagazine.org.nz

The choice of mesh type and location of control joints should be detailed on the drawings and contract documents. Generally NZS 3604 1999 doesnt apply to concrete raft floors in determining joint location and type. Provision of producer statements for. Our concrete fibre slabs have been around longer than our competitors have been in business. Decisions relating to these matters should not be made on site they should be discussed with the designer beforehand.

Source: concretenz.org.nz

Source: concretenz.org.nz

K-Form is made from uPVC. Provision of producer statements for. 1998 Interpolate Insert an intermediate value or term into a series by estimating or calculating it from surrounding known values. Gain access to expert consultants when required for geotechnical considerations design loads minimum slab thickness etc. Its main function is to prevent shrinkage cracks occurring between saw-cut joints.

Source: concretenz.org.nz

Source: concretenz.org.nz

Edge beams and ribs under load bearing walls are 300mm. JOINTS IN CONCRETE RAFT FLOORS All concrete slabs require joints to control the effects of concrete shrinkage. Provision of producer statements for. NZS 36042011 paragraph 7586 sets out the requirements for shrinkage-control joints. Edge beams and ribs under load bearing walls are 300mm.

Source: underconstruction.placemakers.co.nz

Source: underconstruction.placemakers.co.nz

Cutting control joints into the concrete with a diamond saw adds more time on top this. Cutting control joints into the concrete with a diamond saw adds more time on top this. A fresh concrete mixture is a fluid plastic mass that can be molded into virtually any shape but as the material hardens there is a reduction in volume or shrinkage. The Australian code AS 2870 can be used and this code requires movement joints at 18 metres centres maximum. The choice of mesh type and location of control joints should be detailed on the drawings and contract documents.

Source: buildmagazine.org.nz

Source: buildmagazine.org.nz

Do I need to have control joints in the slabs and if so how far apart in a 15-foot-wide driveway. A shrinkage control joint is defined in NZS 3804 as a line along which the horizontal strength of a slab is deliberately reduced so that any shrinkage in the slab will result in a crack forming along that line. Recommended maximum joint spacing is. Waterstop Solutions offers joint sealing and joint repair solutions that are specifically designed to withstand crack and joint movement due to. For slabs designed to NZS 36042011 the spacing of saw-cut joints shrinkage movement joints and location of the reinforcing mesh are all important in avoiding shrinkage cracking.

Source: buildmagazine.org.nz

Source: buildmagazine.org.nz

I really dont want any but dont want cracking either. Armoured Cover Plate Joint. Expansion joints or isolation joints are used between two different concrete pours or where concrete meets with another material or even a structure. Generally NZS 3604 1999 doesnt apply to concrete raft floors in determining joint location and type. Also all too often slabs are thickened at the key thereby providing restraint.

Source: systemfirefighting.blogspot.com

Source: systemfirefighting.blogspot.com

The choice of mesh type and location of control joints should be detailed on the drawings and contract documents. They allow horizontal movement of the slab at right angles to the joint and act to relieve stresses which might otherwise cause random cracking. The overall depth is 305mm. Decisions relating to these matters should not be made on site they should be discussed with the designer beforehand. Both sides of the concrete slab and the vertical faces of the joint are not in bonded contact with each other.

Source: underconstruction.placemakers.co.nz

Source: underconstruction.placemakers.co.nz

A fresh concrete mixture is a fluid plastic mass that can be molded into virtually any shape but as the material hardens there is a reduction in volume or shrinkage. Methods adopted to increase the early shrinkage should not however compromise the integrity or durability of the concrete. I really dont want any but dont want cracking either. Contraction joints control the random drying shrinkage cracking of concrete by inducing the slab to crack at the contraction joints. Cracking is most likely to occur at major changes of plan so NZS 36042011 paragraph 75864 requires that shrinkage control joints.

Source: studylib.net

Source: studylib.net

The Firth RibRaft Floor System is a reinforced concrete waffle raft floor slab-on-ground. NZS 36042011 paragraph 7586 sets out the requirements for shrinkage-control joints. Construction joints must be designed in order to allow displacements between both sides of the slab but at the same time they have to transfer flexural stresses produced in the slab by external loads. Control joints that are cut into the slab should be formed within 2448 hours after pouring depending on the ambient temperature. Contractioncontrol joints are placed in concrete slabs to control random cracking.

Source: buildmagazine.org.nz

Source: buildmagazine.org.nz

Isolation joints also sometimes functioning as expansion joints Construction joints which can also function as contraction joints Contraction joints also sometimes called control joints. Also all too often slabs are thickened at the key thereby providing restraint. Its main function is to prevent shrinkage cracks occurring between saw-cut joints. Expansion joints or isolation joints are used between two different concrete pours or where concrete meets with another material or even a structure. Expansioncontrol joints are placed in concrete slabs to control random cracking whilst accommodating movement.

This site is an open community for users to do submittion their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site good, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title control joints in concrete slabs nz by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.