Your Concrete slab moisture testing methods images are ready in this website. Concrete slab moisture testing methods are a topic that is being searched for and liked by netizens today. You can Get the Concrete slab moisture testing methods files here. Find and Download all royalty-free vectors.

If you’re looking for concrete slab moisture testing methods images information connected with to the concrete slab moisture testing methods topic, you have visit the right blog. Our site always gives you suggestions for downloading the maximum quality video and image content, please kindly hunt and locate more informative video content and graphics that fit your interests.

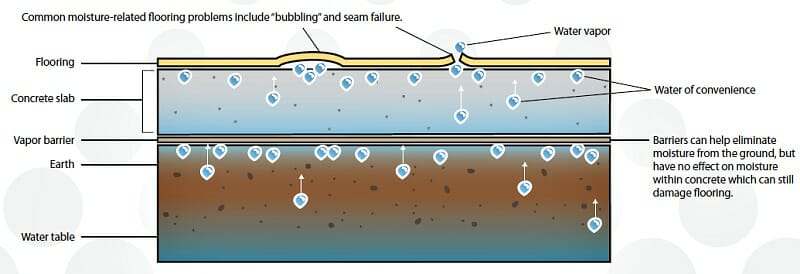

Concrete Slab Moisture Testing Methods. IFTI is the leading independent concrete slab moisture testing company in North America. There are other less-popular or older methods for determining the moisture content within a concrete slab such as the calcium chloride method ASTM F1869 plastic sheet method ASTM D4263 or the calcium carbide method ASTM D4944 MilSpec CRD-C154-77. Because moisture issues are so common an array of concrete moisture testing methods have been developed to address them. There are three standard methods for measuring concrete moisture.

Concrete Moisture Measurement From defelsko.com

Concrete Moisture Measurement From defelsko.com

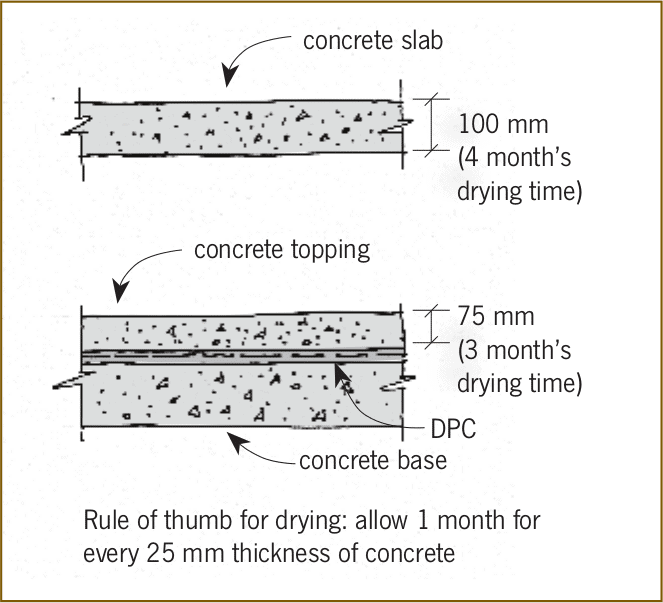

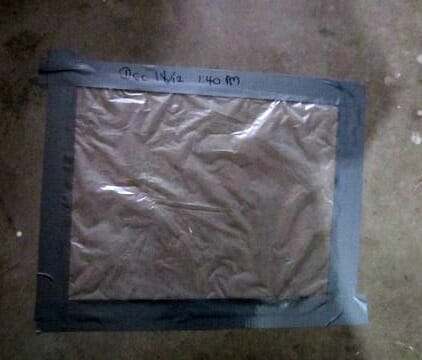

This test involves taping an 18 x 18 polyethylene sheet to a concrete surface and then waiting at least 16 hours. Moisture is usually higher toward the bottom of a concrete slab profile with concentration reduced as the water vapor migrates upward. The Anhydrous Calcium Chloride CaCl2 Moisture Vapor Emission Test has been developed to quantify in a meaningful way the amount of moisture vapor emission from a concrete slab. Standard Test Method for Measuring Moisture Vapor Emission Rate of Concrete Subfloor Using Anhydrous Calcium Chloride. Percent Relative Humidity RH in Concrete Slabs - Preferred Method. There are three standard methods for measuring concrete moisture.

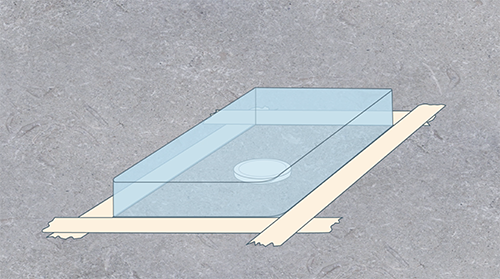

Called the Plastic Sheet Method it involves taping a 457 x 457-mm 18 x 18 in square plastic sheet to the concrete floor and waiting at least 24 hours before removing it.

Firmly press the tape to create a moisture-tight seal with the plastic and concrete. Other methods of measuring the moisture in a concrete slab include creating a chamber above the slab surface sealed to the slab and measured in much the same way as in-situ testing. ASTM F710 pH potential hydrogen. Measures the moisture vapor emission rate MVER of the slab. The most basic test for measuring concrete readiness is ASTM D4263-05 Standard Test Method for Indicating Moisture in Concrete by the Plastic Sheet Method. The above mentioned methods and equipment are used in assessing concrete slabs and their floor systems.

Source: concretemoisture.com

Source: concretemoisture.com

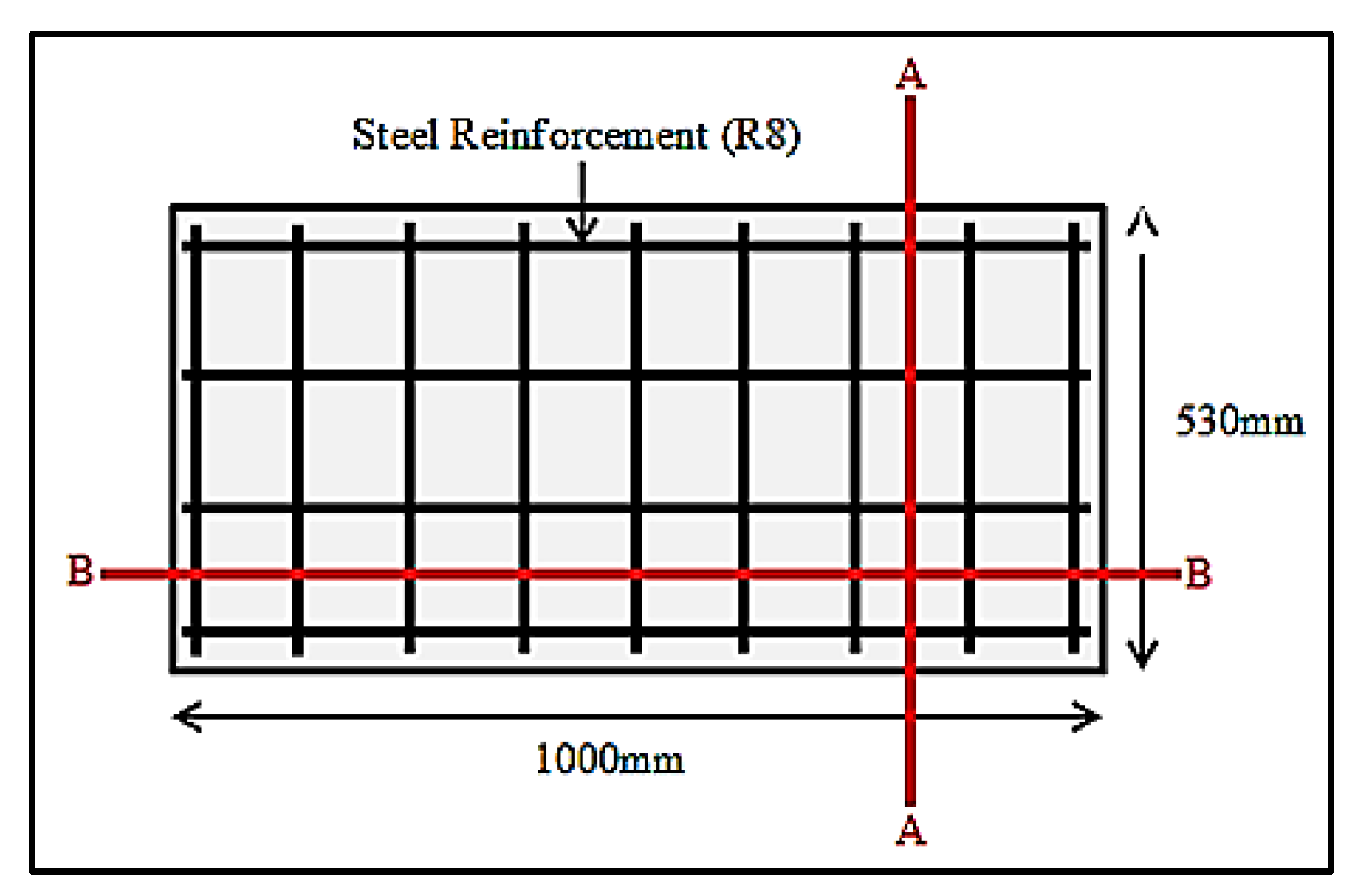

ASTM F710 pH potential hydrogen. Plastic sheet test ASTM D 4263 and calcium chloride test ASTM F 1869 are used to measure concrete moisture and vapor. Concrete Moisture Testing methods exist to provide you with a complete picture of the moisture levels within your concrete which can both help to determine if moisture mitigation is necessary and guide decisions about flooring materials adhesives and sealants. As the name suggests this method calls for small test holes to be drilled into the concrete slab at a depth 40 of the total thickness for slabs on grade 20 from each side of suspended slabs. Spread each plastic square out flat over a dry area of concrete.

Source: duomit.com

Source: duomit.com

Methods for Testing Concrete Moisture Relative Humidity vs. The Anhydrous Calcium Chloride CaCl2 Moisture Vapor Emission Test has been developed to quantify in a meaningful way the amount of moisture vapor emission from a concrete slab. ASTM F1869-04 is the most current edition of this testing protocol. There are several methods which are used to measure moisture qualitatively and quantitatively. Calcium Chloride Internal Relative Humidity Testing RH ASTM F 2170 This process involves measuring the relative humidity of the concrete at a specific depth from the slab surface.

Source: defelsko.com

Source: defelsko.com

Concrete Moisture Testing methods exist to provide you with a complete picture of the moisture levels within your concrete which can both help to determine if moisture mitigation is necessary and guide decisions about flooring materials adhesives and sealants. There are other less-popular or older methods for determining the moisture content within a concrete slab such as the calcium chloride method ASTM F1869 plastic sheet method ASTM D4263 or the calcium carbide method ASTM D4944 MilSpec CRD-C154-77. As the name suggests this method calls for small test holes to be drilled into the concrete slab at a depth 40 of the total thickness for slabs on grade 20 from each side of suspended slabs. RH testing is the most accurate measurement method available to know when concrete is dry enough to install flooring. Spread each plastic square out flat over a dry area of concrete.

Source: concreteconstruction.net

Source: concreteconstruction.net

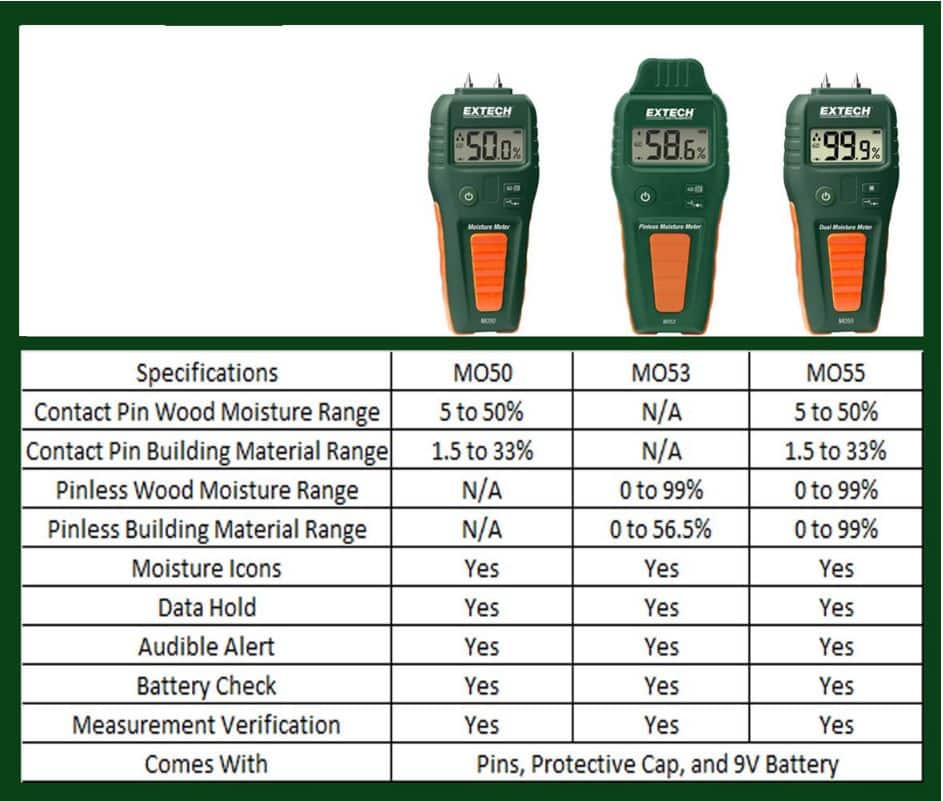

Before you start testing your space should be enclosed with the HVAC up and running. Spread each plastic square out flat over a dry area of concrete. The Concrete Encounter will give you an instant reading of moisture content to over 6 for concrete HC-4972 Cementometer Concrete Moisture Meter Handles normal watercement ratios between 035 to 065 watercement. Percent Relative Humidity RH in Concrete Slabs - Preferred Method. Concrete Relative Humidity Probe Kits based on the ASTM F2170 test method are the most thorough and comprehensive tools used today for the analysis of moisture in the concrete.

Plastic sheet test ASTM D 4263 and calcium chloride test ASTM F 1869 are used to measure concrete moisture and vapor. Plastic sheet test ASTM D 4263 and calcium chloride test ASTM F 1869 are used to measure concrete moisture and vapor. There are other less-popular or older methods for determining the moisture content within a concrete slab such as the calcium chloride method ASTM F1869 plastic sheet method ASTM D4263 or the calcium carbide method ASTM D4944 MilSpec CRD-C154-77. In general moisture testing should be conducted on concrete surfaces that exhibit the final prepared stage before the installation of the flooring material and before installation of smoothing or leveling compounds. Moisture is usually higher toward the bottom of a concrete slab profile with concentration reduced as the water vapor migrates upward.

Source: concretedecor.net

Source: concretedecor.net

The former provides qualitative measure whereas the latter gives quantitative result. Calcium Chloride Internal Relative Humidity Testing RH ASTM F 2170 This process involves measuring the relative humidity of the concrete at a specific depth from the slab surface. For a 6-inch slab on grade the bore hole would be approximately 24 inches. Therefore its advisable to have a floor tested for moisture content prior to installing flooring or moisture barriers. RH testing is the most accurate measurement method available to know when concrete is dry enough to install flooring.

Source: bradthepainter.com

Source: bradthepainter.com

Called the Plastic Sheet Method it involves taping a 457 x 457-mm 18 x 18 in square plastic sheet to the concrete floor and waiting at least 24 hours before removing it. Anhydrous Calcium Chloride Moisture Tests. Concrete Moisture Testing is used to determine the moisture remaining within concrete floor slabs prior to the installation of flooring. This is often called the Plastic Sheet Method or concrete plastic moisture test. Tape along all four edges of the square with duct tape or other waterproof tape.

Source: defelsko.com

Source: defelsko.com

As the name suggests this method calls for small test holes to be drilled into the concrete slab at a depth 40 of the total thickness for slabs on grade 20 from each side of suspended slabs. We are also the experts on industry trends surrounding test methods flooring and mitigation products. As the name suggests this method calls for small test holes to be drilled into the concrete slab at a depth 40 of the total thickness for slabs on grade 20 from each side of suspended slabs. Spread each plastic square out flat over a dry area of concrete. The above mentioned methods and equipment are used in assessing concrete slabs and their floor systems.

Source: defelsko.com

Source: defelsko.com

The former provides qualitative measure whereas the latter gives quantitative result. In particular the use of calcium chloride testing has proven to be inadequate for accurately predicting a final moisture level for lightweight concrete slabs and has been specifically disallowed by the ASTM as a test method for lightweight concrete. Concrete Moisture Testing methods exist to provide you with a complete picture of the moisture levels within your concrete which can both help to determine if moisture mitigation is necessary and guide decisions about flooring materials adhesives and sealants. Standard Test Method for Measuring Moisture Vapor Emission Rate of Concrete Subfloor Using Anhydrous Calcium Chloride. In general moisture testing should be conducted on concrete surfaces that exhibit the final prepared stage before the installation of the flooring material and before installation of smoothing or leveling compounds.

Source: sspc.org

Source: sspc.org

6 Steps to Testing Moisture in Concrete Slabs With the Rapid RH system you can use either the ASTM F2170 test results sheet or a digital app for recording all your RH data. The most effective way to measure moisture in concrete is with an in-situ relative humidity RH test. Moisture is usually higher toward the bottom of a concrete slab profile with concentration reduced as the water vapor migrates upward. ASTM F1869-04 is the most current edition of this testing protocol. Concrete Moisture Testing is used to determine the moisture remaining within concrete floor slabs prior to the installation of flooring.

Source: concreteconstruction.net

Source: concreteconstruction.net

The in-situ RH method is the only option validated through scientific testing to provide an accurate measure of the concretes moisture condition. IFTI is the leading independent concrete slab moisture testing company in North America. The most effective way to measure moisture in concrete is with an in-situ relative humidity RH test. Therefore its advisable to have a floor tested for moisture content prior to installing flooring or moisture barriers. Tape along all four edges of the square with duct tape or other waterproof tape.

Source: concretedecor.net

Source: concretedecor.net

We are also the experts on industry trends surrounding test methods flooring and mitigation products. In general moisture testing should be conducted on concrete surfaces that exhibit the final prepared stage before the installation of the flooring material and before installation of smoothing or leveling compounds. The former provides qualitative measure whereas the latter gives quantitative result. Anhydrous Calcium Chloride Moisture Tests. The in-situ RH method is the only option validated through scientific testing to provide an accurate measure of the concretes moisture condition.

Source: astmd4263.com

Source: astmd4263.com

Use as many squares as needed to test all the main areas that may get flooring. Before you start testing your space should be enclosed with the HVAC up and running. Measures the moisture vapor emission rate MVER of the slab. The above mentioned methods and equipment are used in assessing concrete slabs and their floor systems. Called the Plastic Sheet Method it involves taping a 457 x 457-mm 18 x 18 in square plastic sheet to the concrete floor and waiting at least 24 hours before removing it.

Source: concretemoisture.com

Source: concretemoisture.com

Called the Plastic Sheet Method it involves taping a 457 x 457-mm 18 x 18 in square plastic sheet to the concrete floor and waiting at least 24 hours before removing it. Concrete Relative Humidity Probe Kits based on the ASTM F2170 test method are the most thorough and comprehensive tools used today for the analysis of moisture in the concrete. There are three standard methods for measuring concrete moisture. The former provides qualitative measure whereas the latter gives quantitative result. While the temptation to use do-it-yourself products may reveal itself this is not a do-it-yourself job.

Source: allgaragefloors.com

Source: allgaragefloors.com

The in-situ RH method is the only option validated through scientific testing to provide an accurate measure of the concretes moisture condition. Anhydrous Calcium Chloride Moisture Tests. There are several methods which are used to measure moisture qualitatively and quantitatively. HC-2993BXX Vapor Emission Test Kit Inexpensive solution - commonly known as the Anhydrous Calcium Chloride Vapor Emission Test. In general moisture testing should be conducted on concrete surfaces that exhibit the final prepared stage before the installation of the flooring material and before installation of smoothing or leveling compounds.

Source: bradthepainter.com

Source: bradthepainter.com

The ASTM F2170 relative humidity RH specification supports the latest global standard to measure concrete moisture. Plastic sheet test ASTM D 4263 and calcium chloride test ASTM F 1869 are used to measure concrete moisture and vapor. Percent Relative Humidity RH in Concrete Slabs - Preferred Method. Methods for Testing Concrete Moisture Relative Humidity vs. Concrete Moisture Testing is used to determine the moisture remaining within concrete floor slabs prior to the installation of flooring.

Source: giatecscientific.com

Source: giatecscientific.com

This test involves taping an 18 x 18 polyethylene sheet to a concrete surface and then waiting at least 16 hours. The most effective way to measure moisture in concrete is with an in-situ relative humidity RH test. We are also the experts on industry trends surrounding test methods flooring and mitigation products. Spread each plastic square out flat over a dry area of concrete. Concrete moisture testing methods.

Source: allgaragefloors.com

Source: allgaragefloors.com

Concrete moisture testing methods. The Anhydrous Calcium Chloride CaCl2 Moisture Vapor Emission Test has been developed to quantify in a meaningful way the amount of moisture vapor emission from a concrete slab. The in-situ RH method is the only option validated through scientific testing to provide an accurate measure of the concretes moisture condition. Before you start testing your space should be enclosed with the HVAC up and running. This test involves taping an 18 x 18 polyethylene sheet to a concrete surface and then waiting at least 16 hours.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site convienient, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title concrete slab moisture testing methods by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.