Your Concrete slab high moisture content images are ready in this website. Concrete slab high moisture content are a topic that is being searched for and liked by netizens now. You can Find and Download the Concrete slab high moisture content files here. Download all free vectors.

If you’re searching for concrete slab high moisture content images information linked to the concrete slab high moisture content interest, you have pay a visit to the ideal blog. Our website always gives you hints for viewing the highest quality video and picture content, please kindly search and find more enlightening video articles and images that fit your interests.

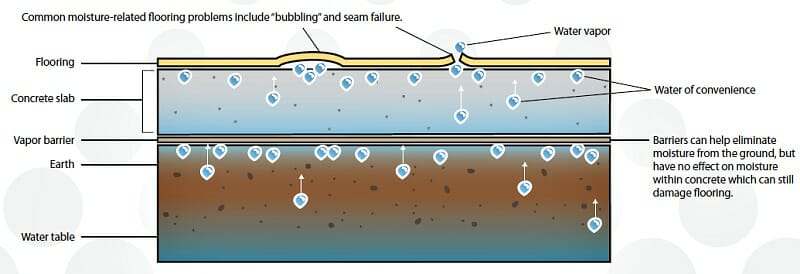

Concrete Slab High Moisture Content. Its crucial to acclimate when the floorboards have a significantly different moisture content from the subfloor and the subfloor is under 12 moisture. Maximum Moisture Content Of Concrete. If the subfloor is above this moisture level take steps to dry out the plywood before acclimating or installing the floorboards. He is exactly right about bulk water and vapor migration upward in a concrete slab.

Remediating Moisture In Concrete Is Not Complicated Concrete Decor From concretedecor.net

Remediating Moisture In Concrete Is Not Complicated Concrete Decor From concretedecor.net

It will take many months for a slab to dry sufficiently to give a top surface RH of 75 even in a well ventilated and weather tight building particularly for ground slabs and slabs on permanent formwork. The concrete floor slab is required to be at service temperature at least 48 hours prior to testing the moisture content. This equates to a moisture content of about 2. This can tell you if the concrete is likely to damage the materials above it or suffer other problems. Why Concrete Moisture Measurement is Important Before applying a protective coating or other flooring materials to a concrete slab it is critical to ensure that the moisture level inside the concrete has decreased to acceptable levelstypically 75 Relative Humidity RH 3 lbs1000 sq. The presence of moisture can prevent the primer from penetrating the concrete and affect the bond of the liquid waterproofing system.

Protect against ingress of water under hydrostatic pressure by ensuring that proper drainage away from the slab is part of the design.

He is exactly right about bulk water and vapor migration upward in a concrete slab. If not addressed properly the moisture vapor. The concrete floor slab is required to be at service temperature at least 48 hours prior to testing the moisture content. The presence of moisture can prevent the primer from penetrating the concrete and affect the bond of the liquid waterproofing system. It is very important to realise that if the slab has been force-dried for example with heating or dehumidification or if the concrete has been rewetted with rain for example the Edney gauge can no longer be used. High levels of moisture in both new and existing concrete substrates can be detrimental to the adhesion of a Sealoflex System.

Source: pinterest.com

Source: pinterest.com

He is exactly right about bulk water and vapor migration upward in a concrete slab. Avoiding problems associated with high moisture content in concrete can be accomplished by the following means. Its crucial to acclimate when the floorboards have a significantly different moisture content from the subfloor and the subfloor is under 12 moisture. If these conditions are not possible tests should be conducted at 75F 10F 24C 5C and RH of. Acceptable moisture levels in concrete according to ASTM standard when testing via ASTM F2170 the RH level of a concrete slab needs to be at or below 75 unless the flooring system manufacturer provides alternate guidelines.

Source: pinterest.com

Source: pinterest.com

If these conditions are not possible tests should be conducted at 75F 10F 24C 5C and RH of. The bottom of the slab usually has a higher moisture content than the top so vapor will move within the interstitial pores of. Avoiding problems associated with high moisture content in concrete can be accomplished by the following means. With this in mind it has been demonstrated that the only way to get an accurate reliable assessment of this true overall moisture condition in older concrete is by taking moisture measurements at specific depths 40 depth for a slab drying from one side and 20 depth for a slab drying from two sides. Excessive moisture present beneath a Sealoflex System can.

Source: pinterest.com

Source: pinterest.com

For instance lifting tile off the floor rotting hardwood damping carpet and coatings delamination. Over time hydrostatic pressure will force that moisture upwards and can cause bubbles in surface treatments and cracks in covering materials that are installed above it. However concrete with a moisture content of 55 is in equilibrium when the relative humidity of the ambient air is 90. Avoiding problems associated with high moisture content in concrete can be accomplished by the following means. It will take many months for a slab to dry sufficiently to give a top surface RH of 75 even in a well ventilated and weather tight building particularly for ground slabs and slabs on permanent formwork.

Source: concretedecor.net

Source: concretedecor.net

The thermo-hygrometers reading of the humidity in the concrete slab will tell you how much excess moisture is present deep in the slab that might evaporate up through the surface. This is a nominal value most product manufacturers specify when concrete is dry enough to allow their product to lay down on it. Added to that beneath continuous flooring moisture can also cause floor darkening or. For instance lifting tile off the floor rotting hardwood damping carpet and coatings delamination. If the concrete is at 5 percent moisture content it will neither absorb nor desorb moisture if the air above it is 70 F 21 C and 75 percent RH.

Source: concretedecor.net

Source: concretedecor.net

Why Concrete Moisture Measurement is Important Before applying a protective coating or other flooring materials to a concrete slab it is critical to ensure that the moisture level inside the concrete has decreased to acceptable levelstypically 75 Relative Humidity RH 3 lbs1000 sq. Drying out will be severely. Figure 1 shows moisture profiles through a drying concrete slab. The concrete floor slab is required to be at service temperature at least 48 hours prior to testing the moisture content. Therefore measuring RH levels at 40 depth of the slab 20 depth if drying on two sides is more representative of the overall humidity conditions of the concrete.

Source: pinterest.com

Source: pinterest.com

Moisture content of concrete changes as it dries. According to ASTM F2170 when drying concrete slabs have lower moisture levels near the surface and higher levels towards the bottom of the slab. Moisture content of concrete changes as it dries. The presence of moisture can prevent the primer from penetrating the concrete and affect the bond of the liquid waterproofing system. Once topped the moisture redistributes itself to a uniform moisture content that may be as high as 5 85 relative humidity.

Source: pinterest.com

Source: pinterest.com

Once topped the moisture redistributes itself to a uniform moisture content that may be as high as 5 85 relative humidity. The presence of moisture can prevent the primer from penetrating the concrete and affect the bond of the liquid waterproofing system. The thermo-hygrometers reading of the humidity in the concrete slab will tell you how much excess moisture is present deep in the slab that might evaporate up through the surface. Ft24 hours MVER or 5 Moisture Content MC. Excessive moisture present beneath a Sealoflex System can.

Source: concretedecor.net

Source: concretedecor.net

Excessive moisture present beneath a Sealoflex System can. Why Concrete Moisture Is Tested If excess moisture is present in a concrete slab when an impermeable surface treatment is installed it will become trapped under that covering. Added to that beneath continuous flooring moisture can also cause floor darkening or. If the subfloor is above this moisture level take steps to dry out the plywood before acclimating or installing the floorboards. Whether you are installing a new concrete slab or you are looking to seal an existing concrete floor in your home or garage application of Original Bone Dry will yield a strong vapor barrier eliminate causes of concrete sweating and mitigate moisture in your cement masonry project.

Source: allgaragefloors.com

Source: allgaragefloors.com

Why Concrete Moisture Measurement is Important Before applying a protective coating or other flooring materials to a concrete slab it is critical to ensure that the moisture level inside the concrete has decreased to acceptable levelstypically 75 Relative Humidity RH 3 lbs1000 sq. If these conditions are not possible tests should be conducted at 75F 10F 24C 5C and RH of. With the use of an insulated box. Figure 1 shows moisture profiles through a drying concrete slab. For instance lifting tile off the floor rotting hardwood damping carpet and coatings delamination.

Source: pinterest.com

Source: pinterest.com

It will take many months for a slab to dry sufficiently to give a top surface RH of 75 even in a well ventilated and weather tight building particularly for ground slabs and slabs on permanent formwork. Drying out will be severely. If not addressed properly the moisture vapor. When considering moisture-sensitive finishes it is important to realise that because of the minute nature of the capillaries within concrete in which moisture is held the concrete can be almost saturated and may still have a moisture content of only about 5 figure 1. Whether you are installing a new concrete slab or you are looking to seal an existing concrete floor in your home or garage application of Original Bone Dry will yield a strong vapor barrier eliminate causes of concrete sweating and mitigate moisture in your cement masonry project.

Source: concretedecor.net

Source: concretedecor.net

When considering moisture-sensitive finishes it is important to realise that because of the minute nature of the capillaries within concrete in which moisture is held the concrete can be almost saturated and may still have a moisture content of only about 5 figure 1. Moisture Content Guidelines Concrete Substrates. However concrete with a moisture content of 55 is in equilibrium when the relative humidity of the ambient air is 90. Figure 1 shows moisture profiles through a drying concrete slab. Excessive moisture present beneath a Sealoflex System can.

Source: pinterest.com

Source: pinterest.com

Why Concrete Moisture Is Tested If excess moisture is present in a concrete slab when an impermeable surface treatment is installed it will become trapped under that covering. The presence of moisture can prevent the primer from penetrating the concrete and affect the bond of the liquid waterproofing system. Therefore if the air inside the box measures less than 75 percent it can be assumed that the mois-ture content of the concrete is less than 5 percent. The concrete floor slab is required to be at service temperature at least 48 hours prior to testing the moisture content. Over time hydrostatic pressure will force that moisture upwards and can cause bubbles in surface treatments and cracks in covering materials that are installed above it.

Source: pinterest.com

Source: pinterest.com

When considering moisture-sensitive finishes it is important to realise that because of the minute nature of the capillaries within concrete in which moisture is held the concrete can be almost saturated and may still have a moisture content of only about 5 figure 1. Why You Should Test a Concrete Slab Subfloor. When considering moisture-sensitive finishes it is important to realise that because of the minute nature of the capillaries within concrete in which moisture is held the concrete can be almost saturated and may still have a moisture content of only about 5 figure 1. It is very important to realise that if the slab has been force-dried for example with heating or dehumidification or if the concrete has been rewetted with rain for example the Edney gauge can no longer be used. Ft24 hours MVER or 5 Moisture Content MC.

Source: pinterest.com

Source: pinterest.com

We have identified the most common causes of excessive concrete moisture. Drying out will be severely. Excessive moisture present beneath a Sealoflex System can. The bottom of the slab usually has a higher moisture content than the top so vapor will move within the interstitial pores of. With this in mind it has been demonstrated that the only way to get an accurate reliable assessment of this true overall moisture condition in older concrete is by taking moisture measurements at specific depths 40 depth for a slab drying from one side and 20 depth for a slab drying from two sides.

Source: pinterest.com

Source: pinterest.com

Maximum Moisture Content Of Concrete. Non-toxic Original Bone Dry Original permanently waterproofs concrete floors to protect your. It is very important to realise that if the slab has been force-dried for example with heating or dehumidification or if the concrete has been rewetted with rain for example the Edney gauge can no longer be used. Once topped the moisture redistributes itself to a uniform moisture content that may be as high as 5 85 relative humidity. Excessive moisture present beneath a Sealoflex System can.

Source: greenbuildingadvisor.com

Source: greenbuildingadvisor.com

With this in mind it has been demonstrated that the only way to get an accurate reliable assessment of this true overall moisture condition in older concrete is by taking moisture measurements at specific depths 40 depth for a slab drying from one side and 20 depth for a slab drying from two sides. Drying out will be severely. Therefore measuring RH levels at 40 depth of the slab 20 depth if drying on two sides is more representative of the overall humidity conditions of the concrete. Excessive moisture present beneath a Sealoflex System can. 1 minute Concrete slabs on grade and basement slabs are weak and vulnerable to the detrimental effect of moisture which may lead to various problems.

Source: concretemoisture.com

Source: concretemoisture.com

Ft24 hours MVER or 5 Moisture Content MC. It will take many months for a slab to dry sufficiently to give a top surface RH of 75 even in a well ventilated and weather tight building particularly for ground slabs and slabs on permanent formwork. Therefore measuring RH levels at 40 depth of the slab 20 depth if drying on two sides is more representative of the overall humidity conditions of the concrete. The thermo-hygrometers reading of the humidity in the concrete slab will tell you how much excess moisture is present deep in the slab that might evaporate up through the surface. If the ambient relative humidity is lower like 60 the equilibrium.

Source: pinterest.com

Source: pinterest.com

Over time hydrostatic pressure will force that moisture upwards and can cause bubbles in surface treatments and cracks in covering materials that are installed above it. If the concrete is at 5 percent moisture content it will neither absorb nor desorb moisture if the air above it is 70 F 21 C and 75 percent RH. Acceptable moisture levels in concrete according to ASTM standard when testing via ASTM F2170 the RH level of a concrete slab needs to be at or below 75 unless the flooring system manufacturer provides alternate guidelines. This is a nominal value most product manufacturers specify when concrete is dry enough to allow their product to lay down on it. When considering moisture-sensitive finishes it is important to realise that because of the minute nature of the capillaries within concrete in which moisture is held the concrete can be almost saturated and may still have a moisture content of only about 5 figure 1.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site serviceableness, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title concrete slab high moisture content by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.