Your A precast concrete wall panel is being hoisted solution images are ready. A precast concrete wall panel is being hoisted solution are a topic that is being searched for and liked by netizens today. You can Find and Download the A precast concrete wall panel is being hoisted solution files here. Find and Download all royalty-free photos and vectors.

If you’re looking for a precast concrete wall panel is being hoisted solution images information connected with to the a precast concrete wall panel is being hoisted solution keyword, you have pay a visit to the ideal site. Our site always provides you with suggestions for viewing the highest quality video and image content, please kindly hunt and locate more enlightening video articles and images that match your interests.

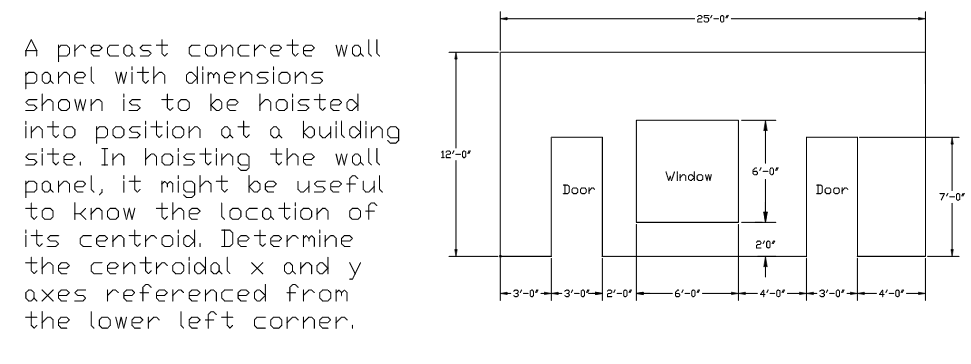

A Precast Concrete Wall Panel Is Being Hoisted Solution. Flexural Stiffness of Sandwich Panels. Whether youre an architect builder contractor or owner Tindall has provided smart solutions. Any precast wall panels carry a minimum service life of 75 years. Create assemblies drawings with automatic dimensions scheduling and sheet.

A Precast Concrete Wall Panel Is Being Hoisted Into Place As Shown The Wall Weighs 18 Kn With The Weight Passing Through Its Center Through Point O Determine The Force T2 Necessary From holooly.com

A Precast Concrete Wall Panel Is Being Hoisted Into Place As Shown The Wall Weighs 18 Kn With The Weight Passing Through Its Center Through Point O Determine The Force T2 Necessary From holooly.com

Describes an investigation of the structural behavior of 31 cancrete sandwich panels tested under uniform flexural loading. Tindalls precast concrete wall panel systems are as durable as they are versatile able to stand. A precast concrete wall panel is being hoisted into place as shown. Formerly a member of the Longley Group of Companies have been supplying precast concrete storage solutions for over 60 years working with many organisations in the construction industry agricultural sector and utilities companies to provide fast and economical storage of liquids and bulk materials. It is from High Concrete Group LLC known for providing peak performance. Precast Concrete Wall Panels.

FP McCann offers an industry leading range of standard and bespoke retaining and containing precast concrete walling solutions.

Tindalls precast concrete wall panel systems are as durable as they are versatile able to stand. The Precast Concrete solution is a tool package made for the precast industry on the Revit platform. Concrete panel construction is increasingly being used for the entire range of buildings from residential to high-rise. Whether youre an architect builder contractor or owner Tindall has provided smart solutions. The precast beams can also provide a base for the construction of block or brick walls. This Briefing Note outlines some of the engineering design issues that should be considered in the use of this type of construction for industrial or commercial applications irrespective of whether the concrete panels are cast on-site or factory precast.

But precast concrete building envelopes dont stop there. But precast concrete building envelopes dont stop there. The designer must appreciate however that the total wall assembly must be designed as a unit to separate the internal and external conditions. It is from High Concrete Group LLC known for providing peak performance. Faster construction times general cost savings that include lower long-term maintenance costs and sustainability are common benefits of utilizing Precast Concrete Solutions structural precast concrete wall panels.

Source: pinterest.com

Source: pinterest.com

Maintenance of precast panels is very little over its life span. Maintenance of precast panels is very little over its life span. Precast concrete Insulated Wall Panels IWP are thermally and structurally efficient systems used in buildings. It is main reason to becoming very popular. Insert details connections and cuts on wall panels.

Source: pinterest.com

Source: pinterest.com

The wall weighs 18 kN with the weight passing through its center through point O. Precast Concrete Wall Panels. Concrete panel construction is increasingly being used for the entire range of buildings from residential to high-rise. Create assemblies drawings with automatic dimensions scheduling and sheet. In some cases precast panels are used as formwork for cast-in- place concrete.

While most walls of this type ore trouble-free defects in some precast walls are forcing those concerned to take a closer look at design and con- struction practices. Naylor Precast previously Whites Concrete Ltd. In particular the present practice of using a precast panel as both the structural unit of the wall and the external facade with insulation on its inside face. The wall weighs 18 kN with the weight passing through its center through point O. All walls include weather tight enclosures for maximum protection against mold and blast-resistant for maximum security and mildew and their superior structural strength makes them highly impactful.

Durability reduces the risk of contamination of the stored material from wall fragments. The precast beams can also provide a base for the construction of block or brick walls. The effectiveness of precast concrete shear walls is largely dependent on the panel-to-panel connections. Product is already Prepared So very little time is required to install it. Bridge Beams Precast Concrete Panels Hollow core slab concrete wall panels precast stairs.

Source: chegg.com

Source: chegg.com

The versatility of Precast Concrete Solutions precast wall panels is unmatched and perfect for complex building designs and structures. This article presents the many benefits that can be derived from using. The wall weighs 18 kN with the weight passing through its center through point O. Precast concrete Insulated Wall Panels IWP are thermally and structurally efficient systems used in buildings. While most walls of this type ore trouble-free defects in some precast walls are forcing those concerned to take a closer look at design and con- struction practices.

Source: in.pinterest.com

Source: in.pinterest.com

The use of prefabricated concrete wall panels for cur- tain walls is gaining popularity in the building industry. Precast concrete has proved to be very useful in todays lifestyle. Our Wall Panel Systems Provide Peak Performance. The precast beams can also provide a base for the construction of block or brick walls. In many cases this integration can also simplify construction and reduce costs.

Source: pinterest.com

Source: pinterest.com

Since concrete is the. Product is already Prepared So very little time is required to install it. Naylor Precast previously Whites Concrete Ltd. A precast concrete wall panel is being hoisted into place as shown. The effectiveness of precast concrete shear walls is largely dependent on the panel-to-panel connections.

25 A precast concrete wall panel is being hoisted into place as shown. It is reusable cost cutter and saving space also. Tindalls precast prestressed concrete wall panels offer innovative design features and economical construction solutions. In many cases this integration can also simplify construction and reduce costs. The precast process was first created in Liverpool England in 1905 by the serial inventor and civil engineer John Alexander Brodie.

The precast process was first created in Liverpool England in 1905 by the serial inventor and civil engineer John Alexander Brodie. Determine the force T necessary for the workers to guide the wall into place. Any precast wall panels carry a minimum service life of 75 years. Maintenance of precast panels is very little over its life span. Precast Concrete enables you to quickly and easily model prefabricated concrete walls floors and columns and.

Source: sciencedirect.com

Source: sciencedirect.com

Determine the force T_2 necessary for the workers to guide the wall into place. Precast Concrete enables you to quickly and easily model prefabricated concrete walls floors and columns and. It is from High Concrete Group LLC known for providing peak performance. In many cases this integration can also simplify construction and reduce costs. The versatility of Precast Concrete Solutions precast wall panels is unmatched and perfect for complex building designs and structures.

Source: holooly.com

Source: holooly.com

Since concrete is the. Whether youre an architect builder contractor or owner Tindall has provided smart solutions. It is from High Concrete Group LLC known for providing peak performance. Maintenance of precast panels is very little over its life span. Naylor Precast previously Whites Concrete Ltd.

Whether youre an architect builder contractor or owner Tindall has provided smart solutions. In some cases precast panels are used as formwork for cast-in- place concrete. This is because concrete has an inbuilt fire resistance property of its own that is present during all stages of construction. The speed at which quality panels are casted and erected has long been the attraction to this method Tindall a leading expert in precast concrete has over 50 years of experience delivering precast concrete solutions that precisely meets their clients needs. In particular the present practice of using a precast panel as both the structural unit of the wall and the external facade with insulation on its inside face.

For a fast and sustainable construction method our solution begins with an insulated sandwich wall panel which includes an exterior concrete skin with variable finishes a continuous layer of insulation and the load bearing structure said Ignacio Cariaga senior cement technical services manager with LeHigh Cement Canada formerly with Armtec the main. Precast Concrete enables you to quickly and easily model prefabricated concrete walls floors and columns and. Faster construction times general cost savings that include lower long-term maintenance costs and sustainability are common benefits of utilizing Precast Concrete Solutions structural precast concrete wall panels. This eliminates potential damage points between the loading shovel and the precast wall unit commonly associated with traditional L and T section wall panels. As a result this offers an inherent advantage over steel and timber solutions.

Source: holooly.com

Source: holooly.com

The versatility of Precast Concrete Solutions precast wall panels is unmatched and perfect for complex building designs and structures. In particular the present practice of using a precast panel as both the structural unit of the wall and the external facade with insulation on its inside face. Since concrete is the. Precast Wall Panels In the case of concrete there is no inherent need to achieve fire resistance by applying additional sprays and linings. Precast concrete Insulated Wall Panels IWP are thermally and structurally efficient systems used in buildings.

Source: sciencedirect.com

Source: sciencedirect.com

1 mm 100 N. Tindalls precast prestressed concrete wall panels offer innovative design features and economical construction solutions. Maintenance of precast panels is very little over its life span. It is from High Concrete Group LLC known for providing peak performance. The use of prefabricated concrete wall panels for cur- tain walls is gaining popularity in the building industry.

Source: kadvacorp.com

Source: kadvacorp.com

The speed at which quality panels are casted and erected has long been the attraction to this method Tindall a leading expert in precast concrete has over 50 years of experience delivering precast concrete solutions that precisely meets their clients needs. Formerly a member of the Longley Group of Companies have been supplying precast concrete storage solutions for over 60 years working with many organisations in the construction industry agricultural sector and utilities companies to provide fast and economical storage of liquids and bulk materials. However the precast concrete wall panel in service can cause problems. The Precast Concrete solution is a tool package made for the precast industry on the Revit platform. Designed to span between steel columns or concrete pad foundations precast ground beams form a permanent shutter around the perimeter of your building to simplify the pouring of concrete floors.

Source: studylib.net

Source: studylib.net

However the precast concrete wall panel in service can cause problems. Naylor Precast previously Whites Concrete Ltd. Our Wall Panel Systems Provide Peak Performance. While most walls of this type ore trouble-free defects in some precast walls are forcing those concerned to take a closer look at design and con- struction practices. For a fast and sustainable construction method our solution begins with an insulated sandwich wall panel which includes an exterior concrete skin with variable finishes a continuous layer of insulation and the load bearing structure said Ignacio Cariaga senior cement technical services manager with LeHigh Cement Canada formerly with Armtec the main.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site convienient, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title a precast concrete wall panel is being hoisted solution by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.