Your A precast concrete wall panel is being hoisted images are ready in this website. A precast concrete wall panel is being hoisted are a topic that is being searched for and liked by netizens today. You can Get the A precast concrete wall panel is being hoisted files here. Get all royalty-free photos and vectors.

If you’re looking for a precast concrete wall panel is being hoisted pictures information related to the a precast concrete wall panel is being hoisted topic, you have visit the ideal site. Our site always provides you with suggestions for refferencing the maximum quality video and picture content, please kindly surf and locate more informative video articles and graphics that match your interests.

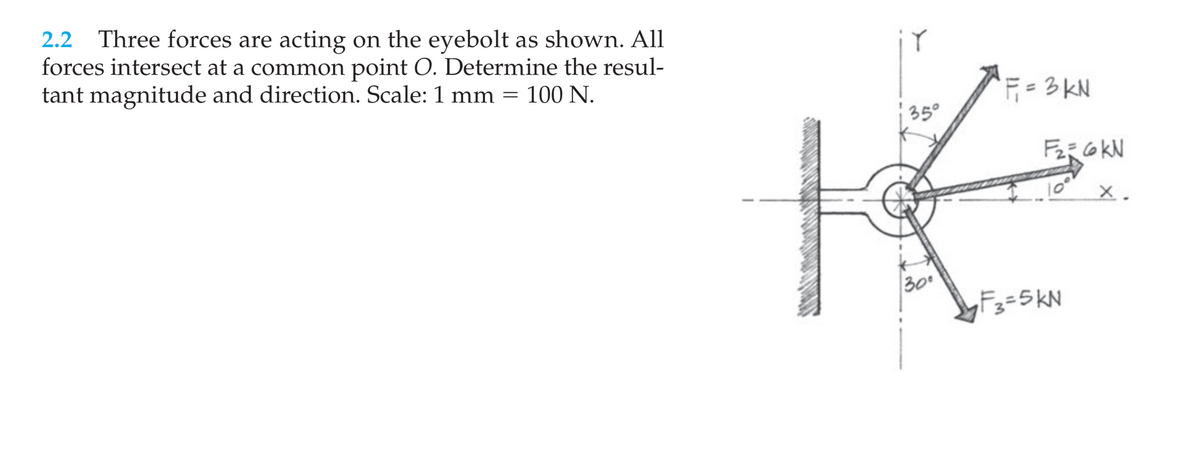

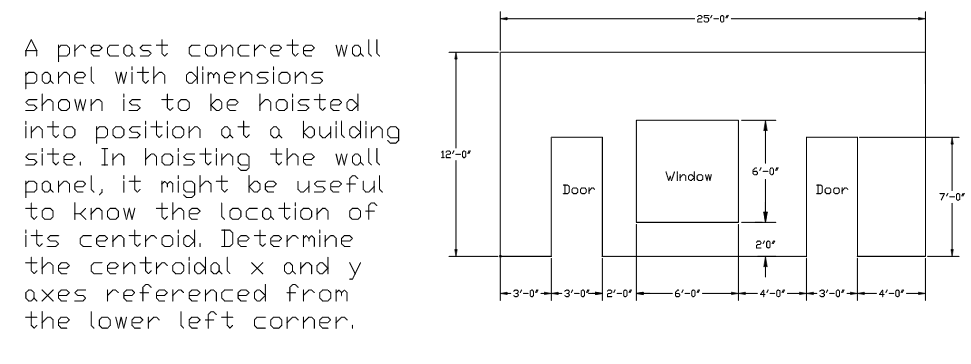

A Precast Concrete Wall Panel Is Being Hoisted. 1 mm 100 N. Precast concrete offers the aesthetics affordability durability strength and speed of installation owners and architects want in a building material. A precast concrete wall panel is being hoisted into place as shown in figure. When erecting precast concrete members the control line shall be erected not less than 6 feet 18 m nor more than 60 feet 18 m or half the length of the member being erected whichever is less from the leading edge.

When erecting precast concrete members the control line shall be erected not less than 6 feet 18 m nor more than 60 feet 18 m or half the length of the member being erected whichever is less from the leading edge. And thus saves time. 1 mm 100 N. The main function of the precast walls is to speed up the construction process. 25 A precast concrete wall panel is being hoisted into place as shown. Precast Concrete construction saves time the risk of project delay is also less.

Some things to be aware of when looking at using precast concrete for a job include.

The precast concrete casting can be carried on simultaneously with other works on site such as earthwork survey etc. Some things to be aware of when looking at using precast concrete for a job include. Solid sandwich and thin-shell. The major one is that on average on-site poured concrete walls have a higher density than precast concrete walls. United States Patent 3952471. -The R value achieved by precast concrete insulated wall panels can vary widely depending on the desired performance of the wall panel-Increased R-values are achieved by increasing the insulation thickness between the two concrete panels-R-values for insulated wall panels range from R-5 to R-50.

But precast concrete building envelopes dont stop there. While the density may be higher you do need to consider the disadvantages of climate and weather to get the high-density result. In some cases precast panels are used as formwork for cast-in-place concrete. Cold weather is not a factor since the panels are cast in a temperature. Precast concrete insulated sandwich wall panels have gained popularity over the years but some industry professionals are still not familiar with them.

Source: shutterstock.com

Source: shutterstock.com

Prefabricated reinforced brick wall panels can be attached to the structural frame without a structural backup wall being required. Precast concrete walls are constructed by casting concrete in a reusable wall mold or form which is then cured in a controlled environment transported to the construction site and lifted into place. A building is quickly erected on the site by preparing a footing below ground level erecting at spaced apart distances around the footing a plurality of vertical pre-cast combined foundation wall and side wall panels of U-cross section which have load bearing vertical side edge flanges and may include a parapet section and then welding. Some things to be aware of when looking at using precast concrete for a job include. A building is quickly erected on the site by preparing a footing below ground level erecting at spaced apart distances around the footing a plurality of vertical pre-cast combined foundation wall and side wall panels of U-cross section which have load bearing vertical side edge flanges and may include a parapet section and then welding infill panels containing windows and.

25 A precast concrete wall panel is being hoisted into place as shown. Cold weather is not a factor since the panels are cast in a temperature. Precast concrete for unusual plan forms. The 5 ft 152 m wide 35 ft 107 m high three-story exterior panels carry the two upper floors and roof see Fig. Precast concrete wall panels and veneer are typically lightweight and easy to install with products.

Source: prezi.com

Source: prezi.com

In contrast cast-in-place concrete is poured into site-specific forms and cured on site. Wall panel size and shape can be af fected by the details and locations of the vertical and horizontal panel-to panel connections. Wall panels can be designed as non-loadbearing or loadbearing carrying floor and roof loads as well as lateral. Solid sandwich and thin-shell. Cold weather is not a factor since the panels are cast in a temperature.

Source: bartleby.com

Source: bartleby.com

The wall weighs 4 kips with the weight passing through its center through point A. A typical warehouse can be erected in a week. Some things to be aware of when looking at using precast concrete for a job include. Wall panel size and shape can be af fected by the details and locations of the vertical and horizontal panel-to panel connections. Precast stone is distinguished from precast concrete using a fine aggregate in.

Source: chegg.com

Source: chegg.com

Precast concrete is a construction product produced by casting concrete in a reusable mold or form which is then cured in a controlled environment transported to the construction site and lifted into place tilt up. Some things to be aware of when looking at using precast concrete for a job include. The wall weighs 4 kips with the weight passing through its center through point A. The effectiveness of precast concrete shear walls is largely dependent on the panel-to-panel connections. The 5 ft 152 m wide 35 ft 107 m high three-story exterior panels carry the two upper floors and roof see Fig.

Source: sciencedirect.com

Source: sciencedirect.com

Precast concrete for unusual plan forms. United States Patent 3952471. Glass-fiber-reinforced concrete curtain wall cladding has several advantages over conventional precast concrete panels. Fabcons VersaCoreGreen Sandwich panel provides outstanding thermal performance. Precast Concrete construction saves time the risk of project delay is also less.

Source: engineer-educators.com

Source: engineer-educators.com

Precast prestressed insulated wall panels are designed for 1 ultimate strength 2 in-service stresses and 3 handling. But precast concrete building envelopes dont stop there. A masonry backup wall is usually preferred to other forms of backup walls. Precast stone is distinguished from precast concrete using a fine aggregate in. A building is quickly erected on the site by preparing a footing below ground level erecting at spaced apart distances around the footing a plurality of vertical pre-cast combined foundation wall and side wall panels of U-cross section which have load bearing vertical side edge flanges and may include a parapet section and then welding infill panels containing windows and.

ORANB WALL PANEL 20 FOOTING Te opULL EXERTED BY WORKBRS. Some things to be aware of when looking at using precast concrete for a job include. Available in a wide variety of colors textures and finishes our precast wall panels are ideal for any building project that needs quick installation and without compromising quality. Solid sandwich and thin-shell. Precast concrete wall panels and veneer are typically lightweight and easy to install with products.

Source: holooly.com

Source: holooly.com

The major one is that on average on-site poured concrete walls have a higher density than precast concrete walls. And thus saves time. Determine the force T necessary for the workers to guide the wall into place. In some cases precast panels are used as formwork for cast-in-place concrete. Solid sandwich and thin-shell.

Source: pinterest.com

Source: pinterest.com

The precast panels act as a form providing the. A typical warehouse can be erected in a week. These can be panelized and erected in either a horizontal or vertical position and used on all types of structures from residential to commercial institutional to industrial. Available in a wide variety of colors textures and finishes our precast wall panels are ideal for any building project that needs quick installation and without compromising quality. -The R value achieved by precast concrete insulated wall panels can vary widely depending on the desired performance of the wall panel-Increased R-values are achieved by increasing the insulation thickness between the two concrete panels-R-values for insulated wall panels range from R-5 to R-50.

Source: holooly.com

Source: holooly.com

A building is quickly erected on the site by preparing a footing below ground level erecting at spaced apart distances around the footing a plurality of vertical pre-cast combined foundation wall and side wall panels of U-cross section which have load bearing vertical side edge flanges and may include a parapet section and then welding. Its continuous 25-inch layer of insulation increases the static R-value by as much as 250 over many construction methods including site-cast panels and CMU construction. Determine the force T2 required for the workers to guide the wall into place. When erecting precast concrete members the control line shall be erected not less than 6 feet 18 m nor more than 60 feet 18 m or half the length of the member being erected whichever is less from the leading edge. The precast concrete casting can be carried on simultaneously with other works on site such as earthwork survey etc.

Source: pinterest.com

Source: pinterest.com

On-site concrete poured walls do have plenty of advantages to consider. A building is quickly erected on the site by preparing a footing below ground level erecting at spaced apart distances around the footing a plurality of vertical pre-cast combined foundation wall and side wall panels of U-cross section which have load bearing vertical side edge flanges and may include a parapet section and then welding infill panels containing windows and. A typical warehouse can be erected in a week. Precast prestressed insulated wall panels are designed for 1 ultimate strength 2 in-service stresses and 3 handling. The key factors which regulate the quality of construction such as curing temperature mix design formwork etc.

Precast concrete wall panels and veneer are typically lightweight and easy to install with products. There are many reasons to use precast concrete products for construction landscaping and. Precast Concrete construction saves time the risk of project delay is also less. Also calculate cable tension T1. And thus saves time.

Source: studylib.net

Source: studylib.net

ORANB WALL PANEL 20 FOOTING Te opULL EXERTED BY WORKBRS. Precast Concrete construction saves time the risk of project delay is also less. Determine the force T2 required for the workers to guide the wall into place. The vast majority of the insulating properties. The effectiveness of precast concrete shear walls is largely dependent on the panel-to-panel connections.

Source: constructionequipmentguide.com

Source: constructionequipmentguide.com

A typical warehouse can be erected in a week. Precast concrete is a construction product produced by casting concrete in a reusable mold or form which is then cured in a controlled environment transported to the construction site and lifted into place tilt up. Precast concrete offers the aesthetics affordability durability strength and speed of installation owners and architects want in a building material. Precast concrete wall panels and veneer are typically lightweight and easy to install with products. The vast majority of the insulating properties.

Determine the force T necessary for the workers to guide the wall into place. When erecting precast concrete members the control line shall be erected not less than 6 feet 18 m nor more than 60 feet 18 m or half the length of the member being erected whichever is less from the leading edge. A typical warehouse can be erected in a week. A masonry backup wall is usually preferred to other forms of backup walls. Solid sandwich and thin-shell.

Source: pinterest.com

Source: pinterest.com

Huffcutts wall panels stand the test of time while providing an aesthetically pleasing appearance that is low maintenance and durable. Precast concrete is a construction product produced by casting concrete in a reusable mold or form which is then cured in a controlled environment transported to the construction site and lifted into place tilt up. The wall weighs 18 kN with the weight passing through its center through point O. In contrast cast-in-place concrete is poured into site-specific forms and cured on site. Reasons for their increased use in place of more traditional materials include.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site good, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title a precast concrete wall panel is being hoisted by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.